Method of using rotational multiaxial borehole pouring concrete occluding pile wall for enclosing deep foundation pit and slope protection project

A technology of occlusal piles and engineering, which is applied in the direction of foundation structure engineering, sheet pile walls, excavation, etc., to achieve the effect of speeding up construction, reducing project cost, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

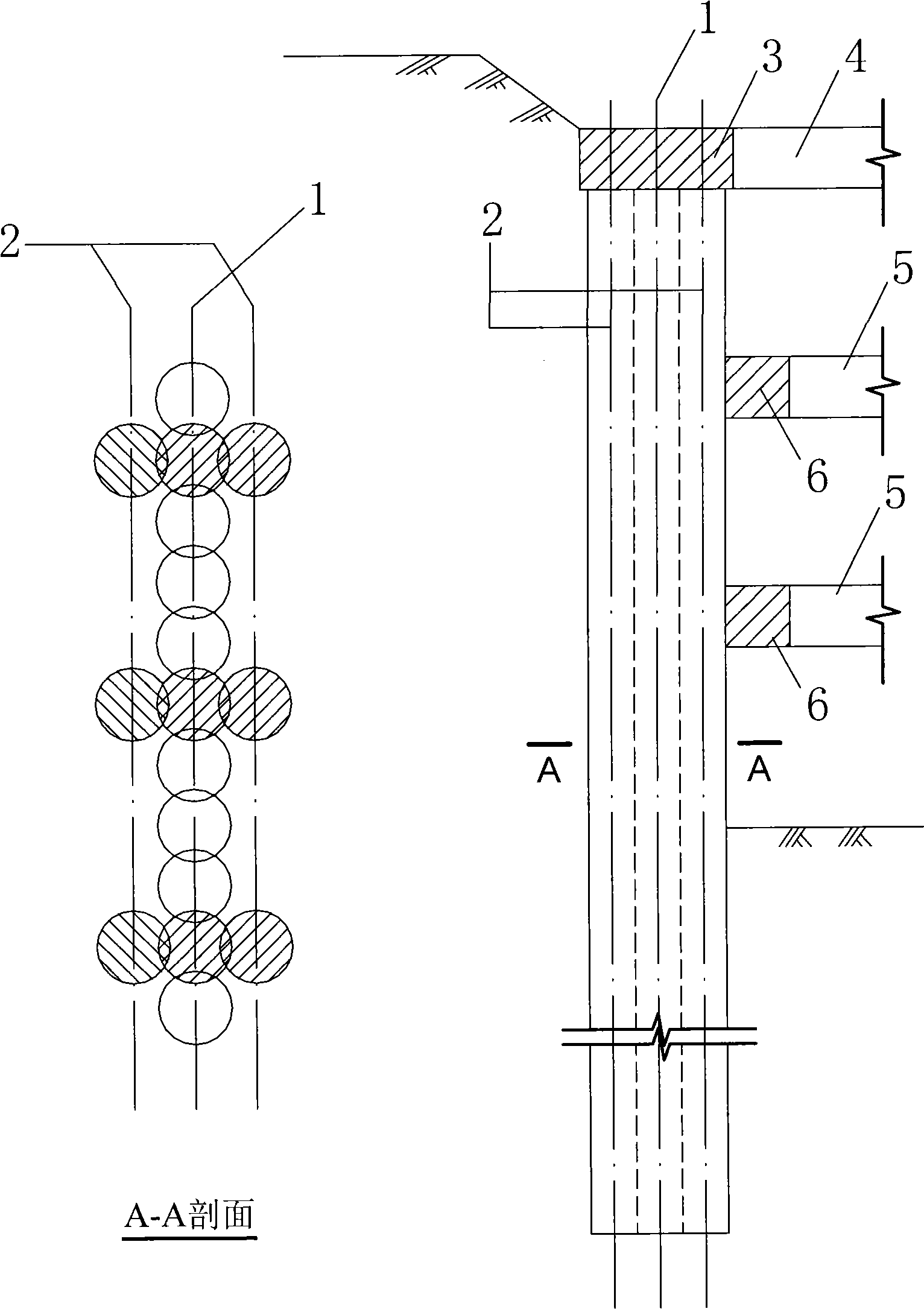

[0036] Embodiment 1: The internal support in multi-storey basement, subway or underground space excavation and other deep foundation pits combined with multi-axis drilling and pouring concrete occlusal protection pile wall enclosure method.

[0037] This enclosure structure is suitable for the excavation enclosure of various multi-storey basements, subways and underground spaces, and the specific implementation is to set multi-axis drilling and pouring concrete occlusal enclosure pile walls along the basement enclosure. This kind of retaining pile wall can be a method of pure rotatable multi-axis drilling and pouring surrounding retaining pile wall (Figure 4), or a method of cement-soil wall combined with rotatable multi-axis drilling and pouring concrete to occlude the retaining pile wall (Figure 5 ). According to the excavation depth, excavate from top to bottom while pouring each layer of reinforced concrete top beams or enclosure beams and supports to form a complete enclo...

Embodiment 2

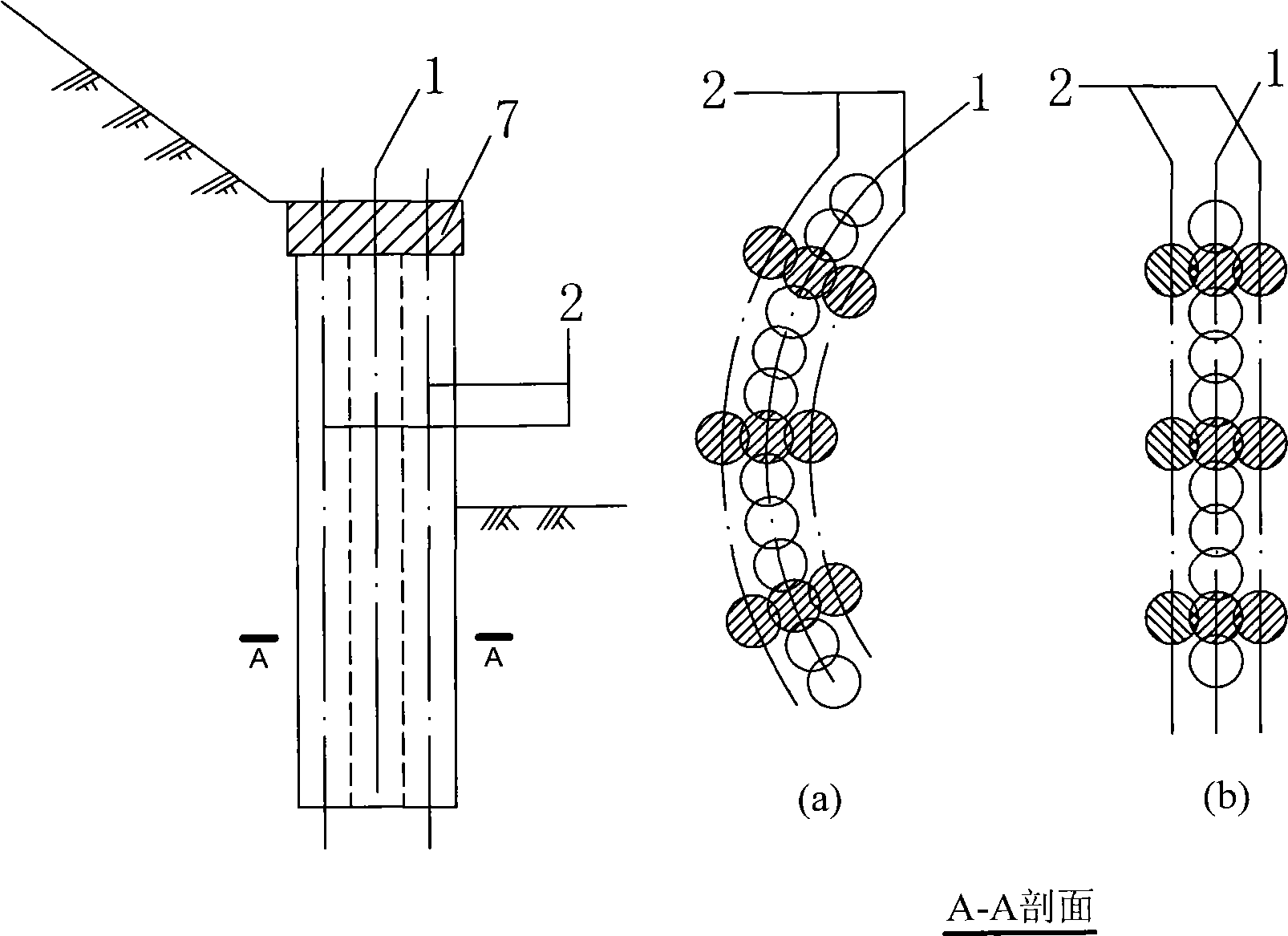

[0038] Embodiment 2: The method of cantilever multi-axis drilling and pouring concrete occlusal pile wall enclosure in slope protection engineering.

[0039] This enclosure structure is suitable for mountain slope protection projects, and multi-axis drilling and pouring concrete occlusal enclosure pile walls are drilled along the slope protection axis. This kind of enclosure structure can be purely rotatable multi-axis drilling and pouring concrete to occlude the enclosure pile wall (Fig. 4), or it can be a method of cement-soil wall combined with rotatable multi-axis drilling and pouring enclosure retaining pile wall (Fig. 5) , so that a cantilever enclosure structure is formed, and reinforced concrete pressure beams are generally poured on the top of the enclosure pile wall to enhance the integrity of the enclosure structure. According to the plane distribution of the slope protection, the axis of the retaining pile wall can be a straight line, or it can be set in a circular...

Embodiment 3

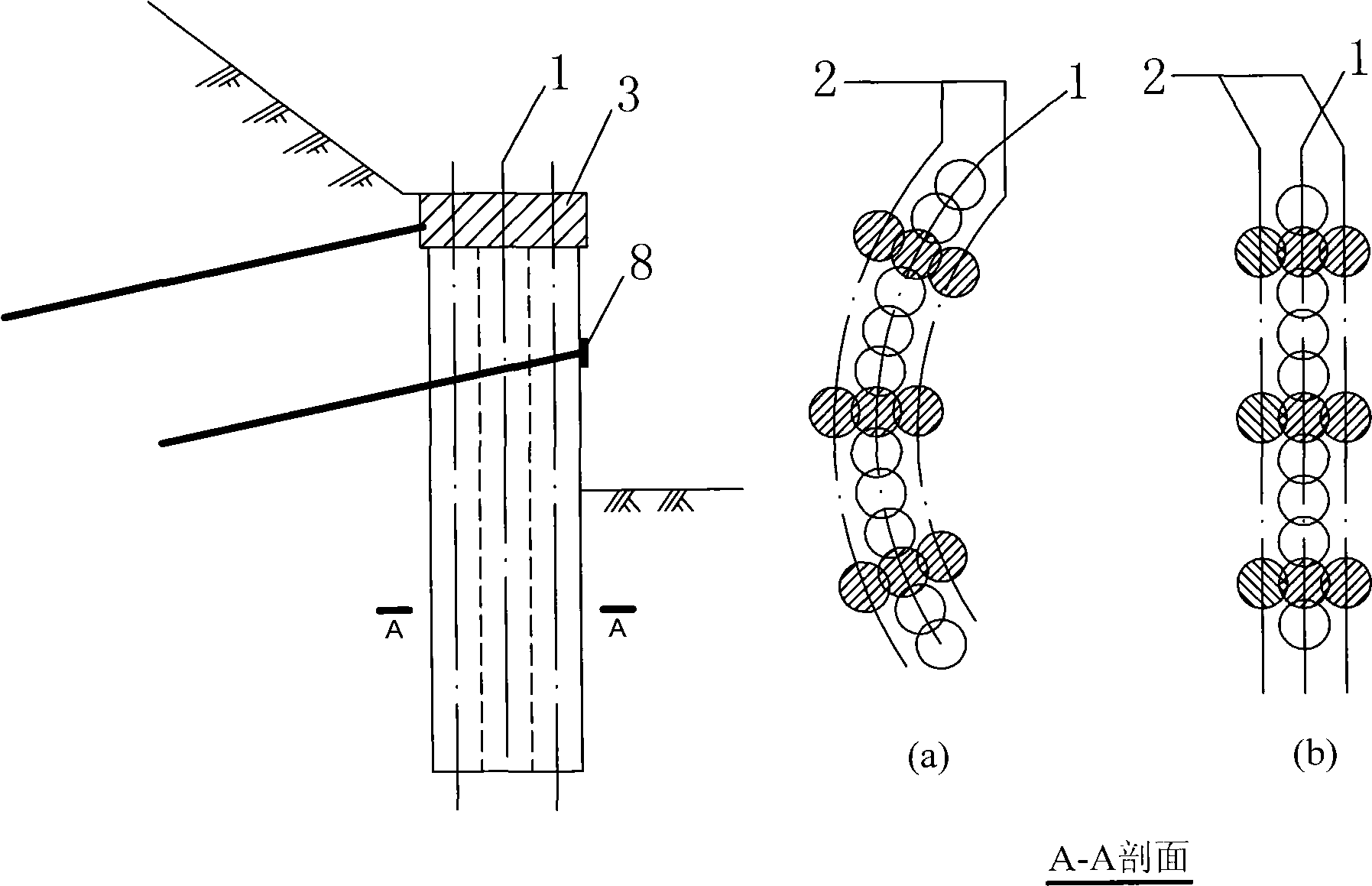

[0040] Example 3: Multi-axis drilling and pouring concrete occlusal enclosure method with anchor rods in slope protection engineering This enclosure structure is also suitable for mountain slope protection engineering, and multi-axial drilling and pouring concrete occlusal is set along the slope protection axis Guard pile wall. This kind of enclosure structure can be purely rotatable multi-axis drilling and pouring concrete to occlude the enclosure pile wall (Fig. 4), or it can be a method of cement-soil wall combined with rotatable multi-axis drilling and pouring enclosure retaining pile wall (Fig. 5) . One or more rows of anchor rods are laid on the top and middle of the enclosure wall, and the anchor rods and the enclosure wall form a complete enclosure structure by using the reinforced concrete pressure beam on the top of the enclosure wall and the enclosure beam in the middle of the enclosure wall ( image 3 ). The axis of the pile wall can also be straight or arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com