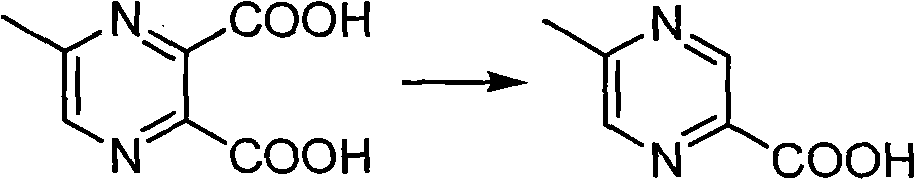

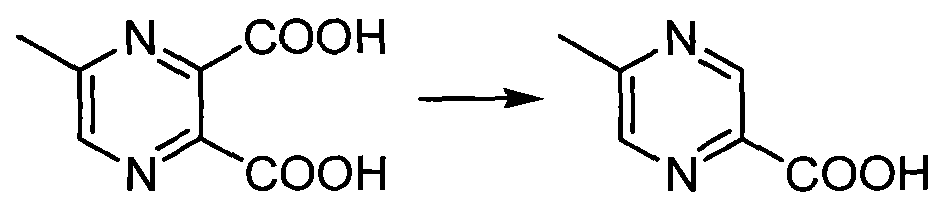

Method for preparing 5-methylprazine-2-carboxylic acid

A technology of methylpyrazine and pyrazine dicarboxylic acid, applied in chemical instruments and methods, organic decomposition, organic chemistry, etc., can solve the problems of harsh conditions, unfavorable large-scale production, and high temperature, and achieves less by-products, green environmental protection Mild conditions and highly selective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 80g of 5-methyl-2,3-pyrazinedicarboxylic acid to the 2L four-necked bottle And 0.96kg saturated saline (10ml / g), warming up to 110oC reflux reaction for 10h. When the reaction is carried out until the HPLC shows that the conversion rate is 91%, it is cooled to room temperature, and the filtrate is filtered with 1.6kg butanone (25mL / g), the organic phase is combined and concentrated, cooled and crystallized in an ice-water bath, and the product is obtained by suction filtration 33.5 g. HPLC purity: 98%, isomer impurity content: 1.1%, yield: 55%.

Embodiment 2

[0019] Add 36g of 5-methyl-2,3-pyrazinedicarboxylic acid to the 2L four-necked bottle And 349g saturated brine (8ml / g), warming up to 108oC reflux reaction 8h. When the reaction is carried out until the HPLC shows that the conversion rate is 92%, it is cooled to room temperature, suction filtered, and the filtrate is concentrated with 524g butanone (18mL / g), the organic phase is combined, cooled and crystallized in an ice-water bath, and the product 15.3 g. HPLC purity: 98%, isomer impurity content: 0.7%, yield: 56.2%.

Embodiment 3

[0021] Add 54g of 5-methyl-2,3-pyrazinedicarboxylic acid to the 2L four-necked bottle And 327g saturated brine (5ml / g), warming up to 105oC reflux reaction 8h. When the reaction is carried out until the HPLC shows that the conversion rate is 90%, it is cooled to room temperature, suction filtered, and the filtrate is concentrated with 655g butanone (15mL / g), the organic phase is combined, cooled and crystallized in an ice-water bath, and the product 22.5 is obtained by suction filtration. g. HPLC purity: 98%, isomer impurity content: 2.0%, yield: 55%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com