Method and device for separating oil and water

A technology of oil-water separation and oil-water mixing, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., and can solve the problems of affecting the separation efficiency of spiral tubes and the deterioration of separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

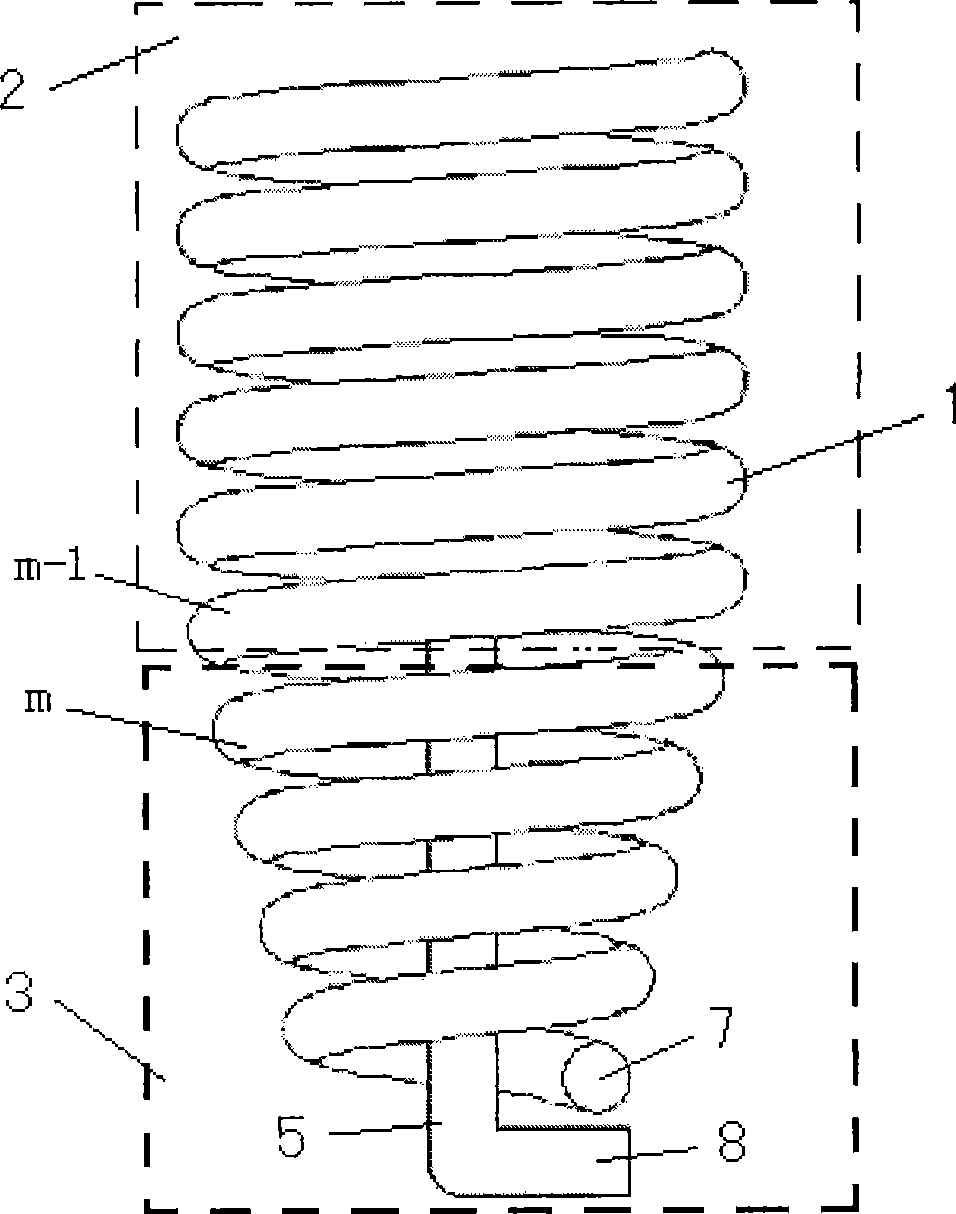

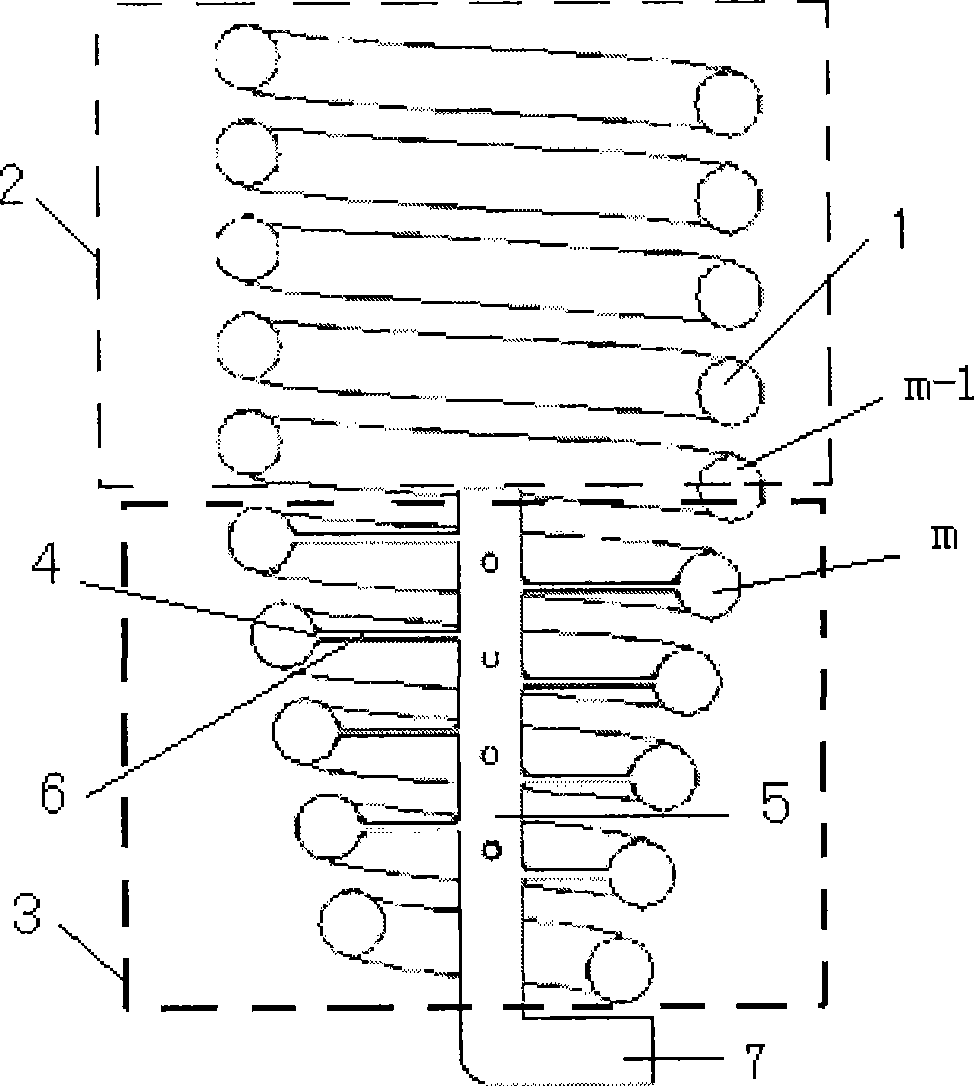

[0022] Such as figure 1 , figure 2 As shown, the present invention is provided with a helical tube 1, and the helical tube 1 is divided into a cylindrical upper tube 2 with an equal radius of rotation and a lower tube 3 with an inverted tapered radius of rotation. A plurality of holes 4 are arranged at intervals inside the tube wall of the lower tube 3, and an oil collecting pipe 5 is arranged in the center of the lower tube 3, and the oil collecting tube 5 is connected with corresponding holes 4 on the inner wall of the lower tube 3 through several connecting pipes 6.

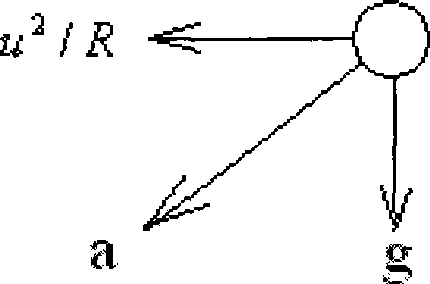

[0023] The present invention makes use of the density difference between oil and water and the centrifugal force generated by the rotating flow of the oil-water mixture in the spiral tube 1, so that the oil-water mixture gradually separates in the upper tube 2 and enters the lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com