connection socket

A technology of sockets and connecting parts, which is applied in the direction of connection, fixed connection, parts of connection devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

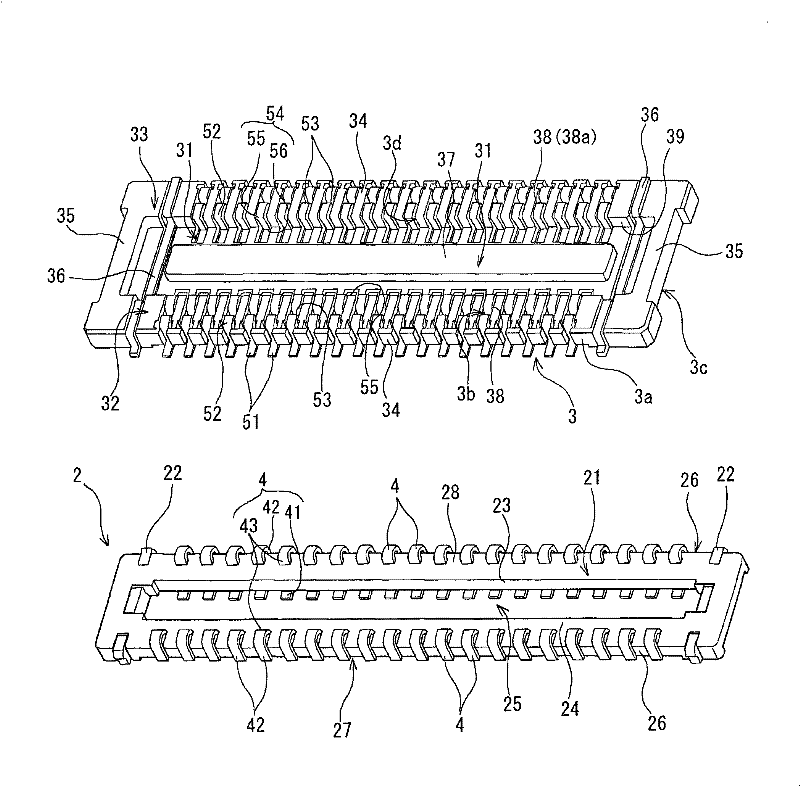

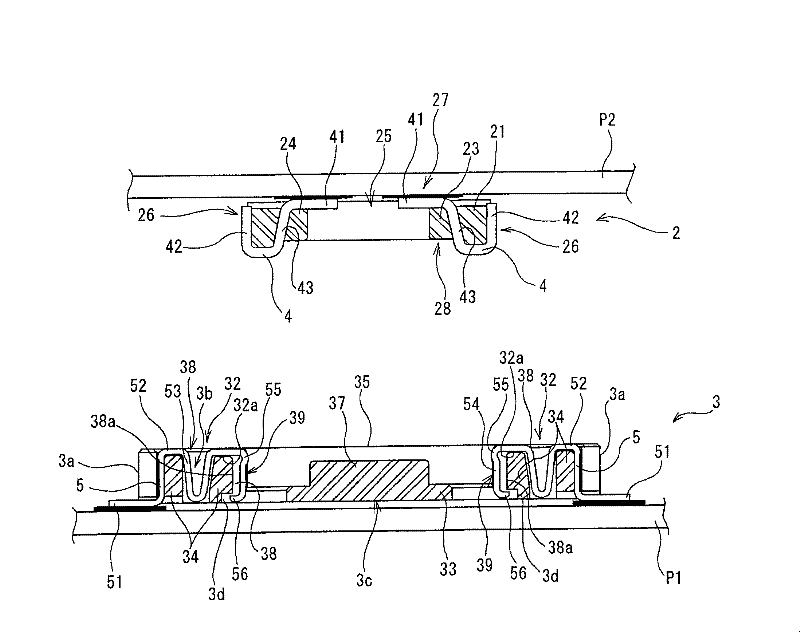

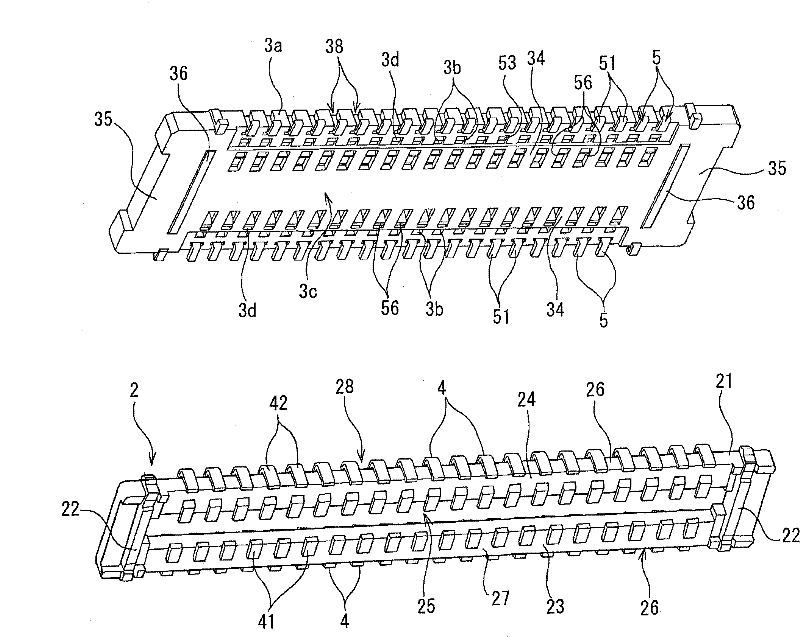

[0066] Embodiment 1 of the present invention will be described below with reference to the drawings. figure 1 is a perspective explanatory view showing Embodiment 1 of the present invention, figure 2 It is a central sectional explanatory view showing Embodiment 1 of the present invention, image 3 is a perspective explanatory view showing Embodiment 1 of the present invention, Figure 4 It is a central sectional explanatory view showing the fitting state of Example 1.

[0067] Reference numeral 1 is a board-to-board connector as Embodiment 1 of the present invention. Connector 1 (hereinafter simply referred to as connector 1) is composed of a plug 2 mounted on a second printed wiring board P2 and a connecting socket 3 mounted on a first printed wiring board P1 as a first connection object (hereinafter referred to as The socket 3) is configured to connect the pin 2 to the socket 3 and to electrically connect the first printed wiring board P1 and the second printed wiring b...

Embodiment 2

[0089] In the first embodiment described above, the connection connector 1 is used to electrically connect the first printed wiring board P1 and the second printed wiring board P2. Example 2 of the structure using the plug 2 as an electronic module as an electronic component is connected to P1.

[0090] Figure 5 It is a perspective explanatory drawing which shows Example 2.

[0091] In the case where the electronic module 2a is formed as a plug and must be connected to the printed wiring board as in Embodiment 2, it is because the electronic module 2a is afraid of heat and has low heat resistance, so it cannot withstand heat such as soldering and when it is repaired. Easy attachment and detachment is necessary and the fixing to the printed wiring board by a fixing method such as soldering is not appropriate. Of course, it can also be used in other cases.

[0092] In the second embodiment, the electronic module 2 a is provided with the latch contacts 4 similarly to the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com