Optimal design method of subwavelength metal polarization beam splitting grating

A polarization beam splitting and subwavelength technology, applied in diffraction gratings, optics, optical components, etc., can solve the problem of wrong parameter selection, inability to solve the problems of grating period, width ratio groove depth, etc., to achieve the effect of improving scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

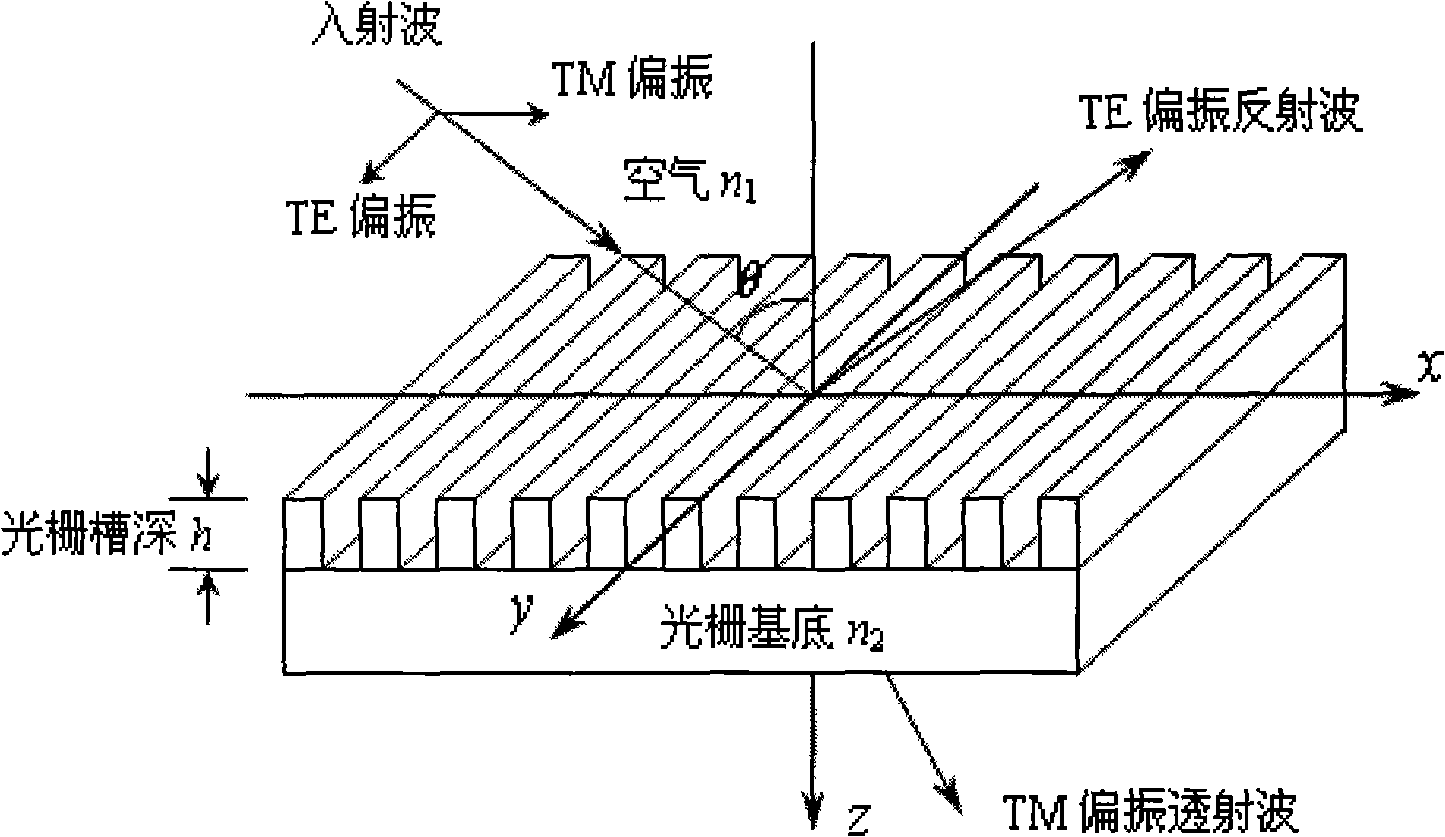

[0021] The sub-wavelength metal polarization beam-splitting grating is designed below for the working wavelength of 1550 nanometers, and the specific optimization design process of the present invention is described in detail. The required sub-wavelength metal polarization beam-splitting grating structure is as follows figure 1 shown.

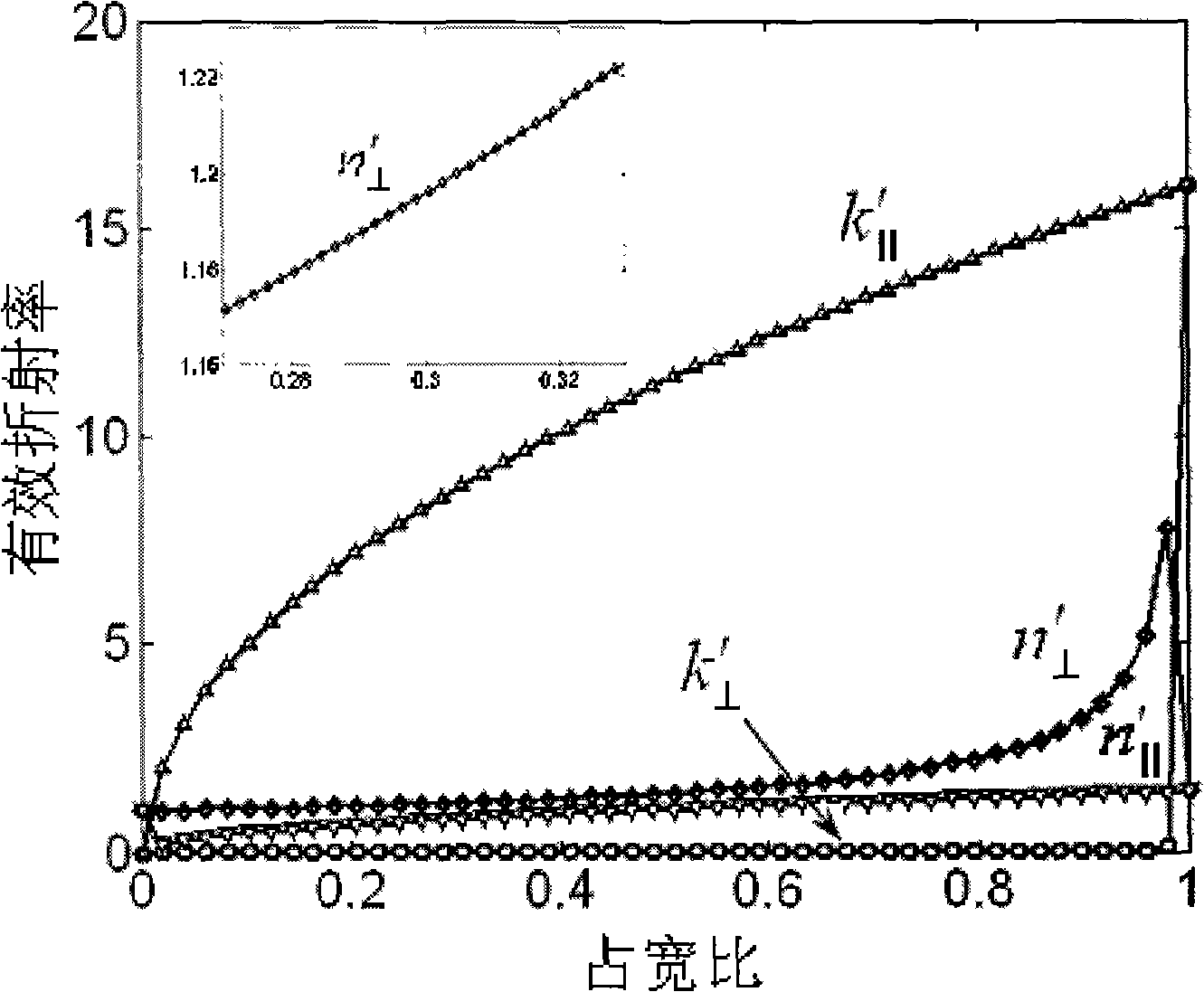

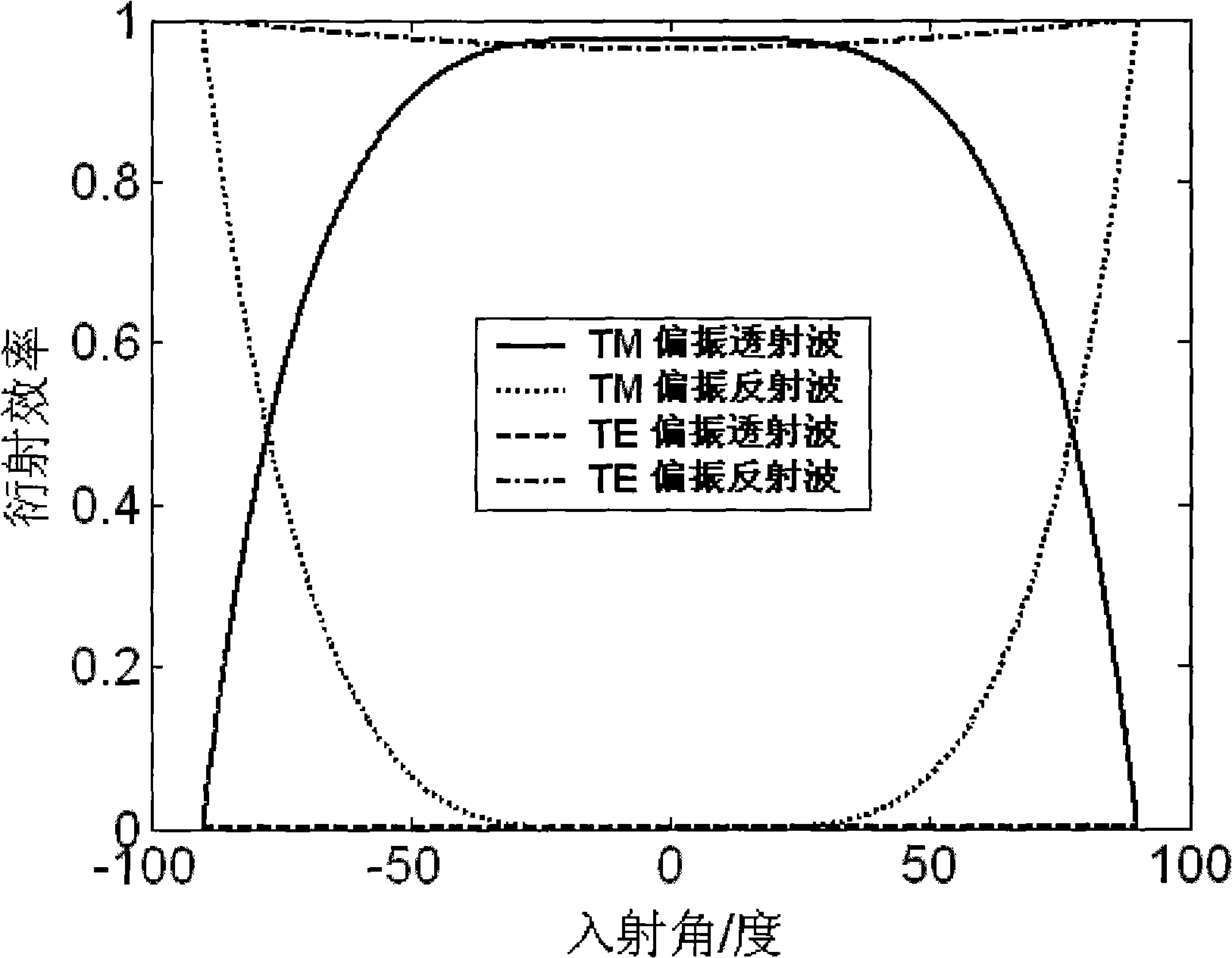

[0022] Step 1: Determine the grating period Λ. According to the periodic condition of the subwavelength grating (Λ≤λ 0 / 10), determine the working wavelength λ 0 = 1550 nanometers grating period Λ ≤ 155 nanometers, in order to reduce processing difficulty, usually take the upper limit of the grating period Λ = 150 nanometers, at this time there is only 0 order diffraction in the grating.

[0023] Step 2: Determine the effective refractive index required for maximum transmission of the TM polarization. The sub-wavelength metal grating is equivalent to a metal film for TE polarized light, which has reflection characteristics, and is equivalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com