Coupling device for double core optical fiber and manufacturing method thereof

A dual-core optical fiber and coupling device technology, which is applied in the coupling of optical waveguides, clad optical fibers, optical waveguide light guides, etc., can solve the problems that multi-core optical fiber beam splitting cannot be realized, and the connection problem has not been effectively solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

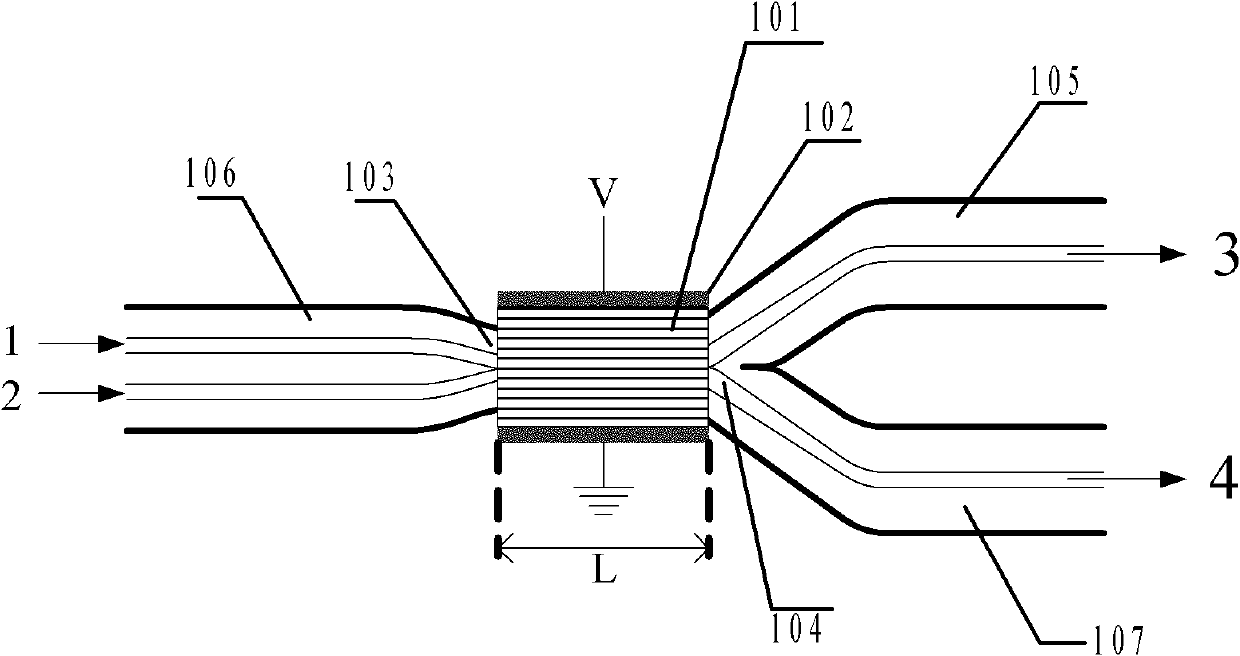

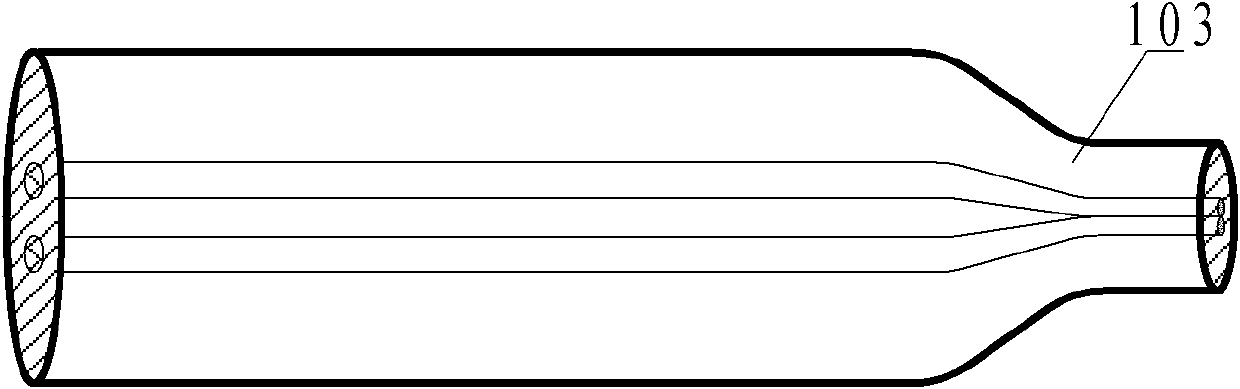

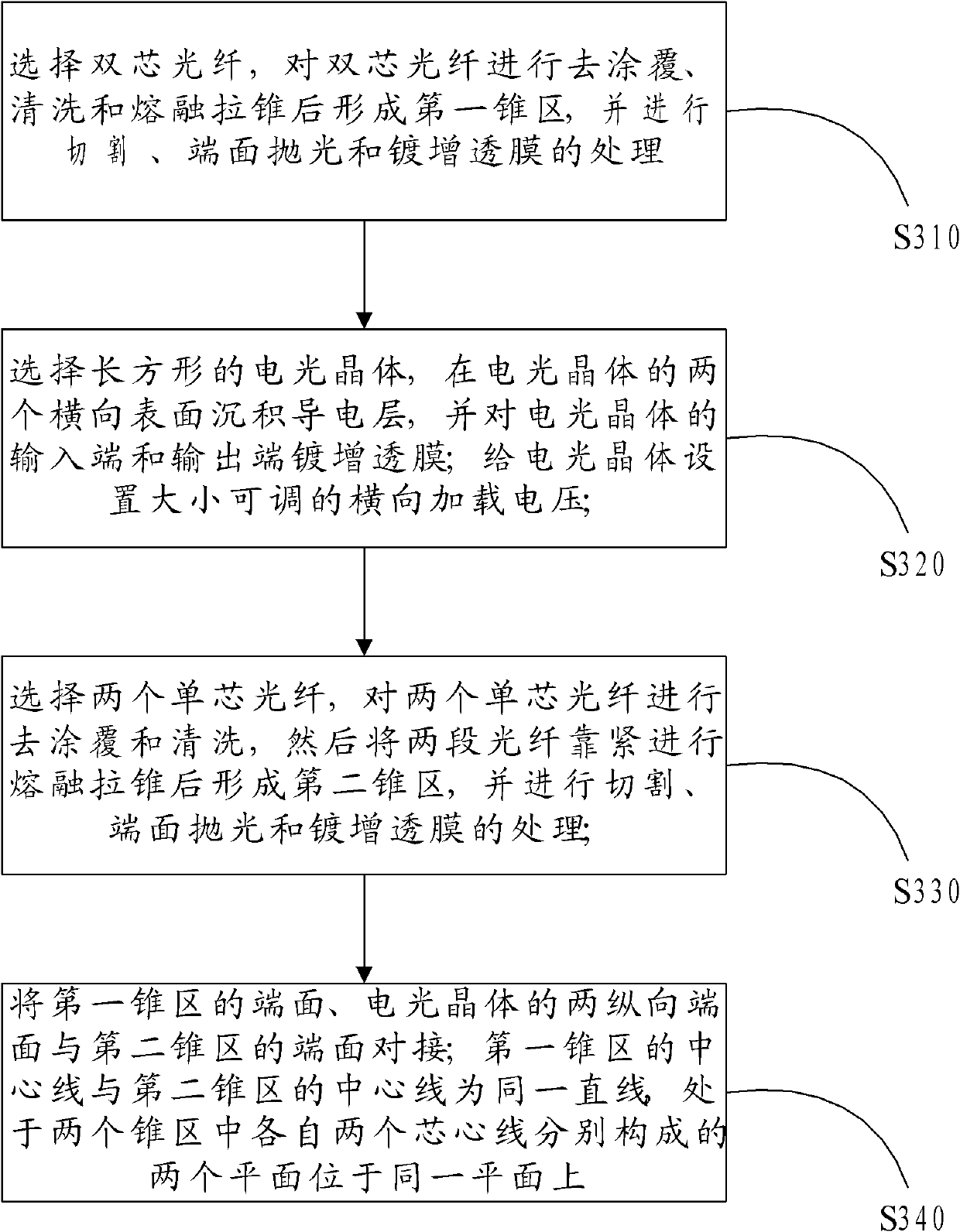

[0035] refer to figure 1 and figure 2, in this embodiment, the coupling device of double-core fiber comprises: double-core fiber 106 (comprising input fiber core 1 and input fiber core 2), the electro-optic crystal 101 that is connected with double-core fiber 106; And, respectively with electro-optic crystal 101 The first single-core optical fiber 105 (comprising the output core 3) and the second single-core optical fiber 107 ((comprising the output core 4)) that are connected; A single-core optical fiber 105 and a second single-core optical fiber 107 comprise a second tapered region 104 formed after melting and tapering; the centerline of the first tapered region 103 is the same straight line as the centerline of the second tapered region 104; the first tapered region 103 The plane formed by the two core wires and the plane formed by the two core wires in the second cone area 104 are the same plane; and the end of the first cone area 103, the end of the electro-optic crysta...

Embodiment 2

[0038] refer to figure 1 and figure 2 , in this embodiment, the coupling device of double-core fiber comprises: double-core fiber 106 (comprising input fiber core 1 and input fiber core 2), the electro-optic crystal 101 that is connected with double-core fiber 106; And, respectively with electro-optic crystal 101 The first single-core optical fiber 105 (comprising the output core 3) and the second single-core optical fiber 107 ((comprising the output core 4)) that are connected; A single-core optical fiber 105 and the second single-core optical fiber 107 comprise the second tapered region 104 formed after melting and drawing; the centerline of the first tapered region 103 is the same straight line as the centerline of the second tapered region 104; in the first tapered region The plane formed by the two core wires is the same plane as the plane formed by the two core wires in the second cone area; and the end of the first cone area 103, the end of the electro-optic crystal 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com