Orifice plate type rock surface roughness mechanical measuring apparatus

A surface roughness and measurement technology, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of positioning error, expensive equipment, affecting the accuracy of the measured surface roughness, etc., and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

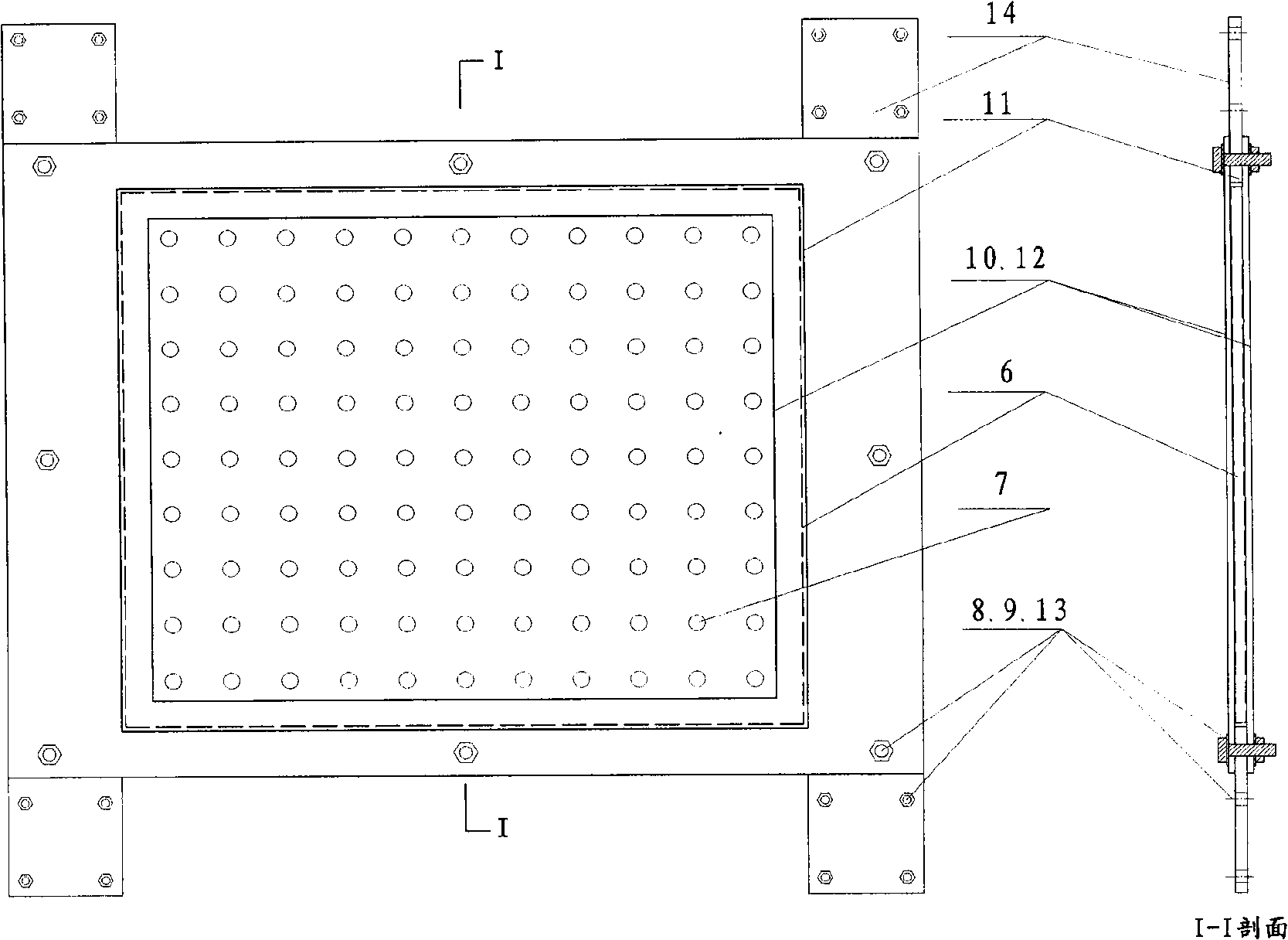

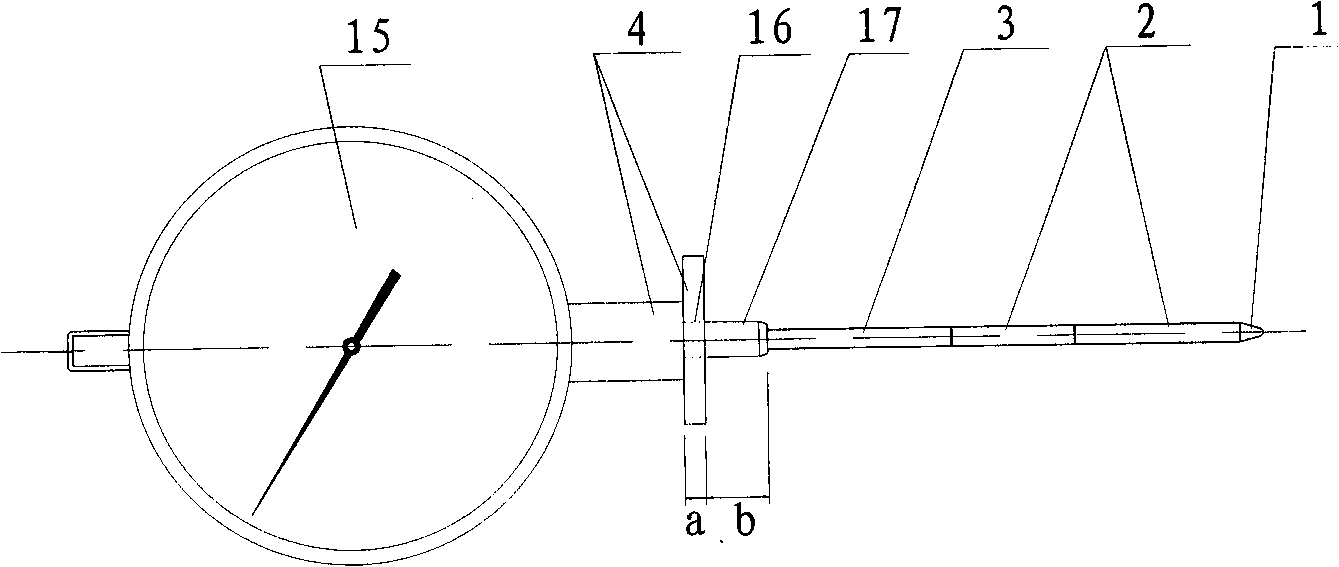

[0041] The invention provides a method for measuring rock surface roughness. The invention mainly includes a transparent test plate 6 with hole group distribution, three-layer protective frames 10-12, a strip joint plate 21, a right-angle joint plate 22, a frame-plate joint 14, and a hundred sub-table 5. Refer below Figure 1-Figure 5 And according to the manufacture and measurement process of the embodiment, the measurement method of the invention is described in detail.

[0042] In general, the length and width of the transparent measuring board are equal to (or slightly less than) the length and width of the hollow part of the middle protective frame 11, and greater than the length and width of the upper and lower protective frames 10 and 12 hollow parts, and its thickness is equal to ( Or slightly less than) the thickness of the middle layer protective frame 11, so the transparent measuring board 6 can be completely fixed by the upper, middle and lower three layers of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com