Stress absorbing load bearing complex structure of high viscosity asphalt gap grading

A technology of high-viscosity asphalt and composite structure, which can be applied to cohesive pavement paved on site, roads, roads, etc., and can solve problems such as doubts about the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

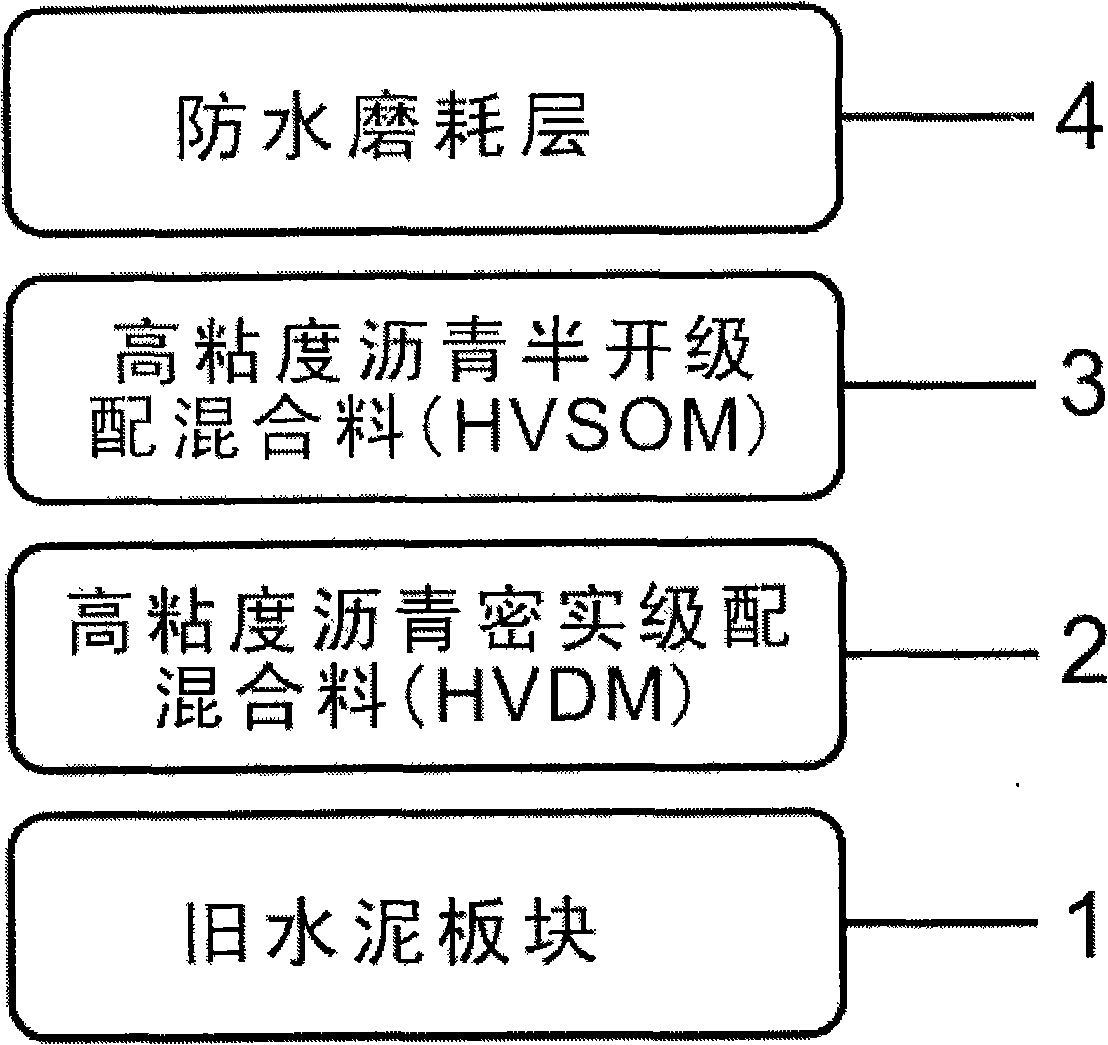

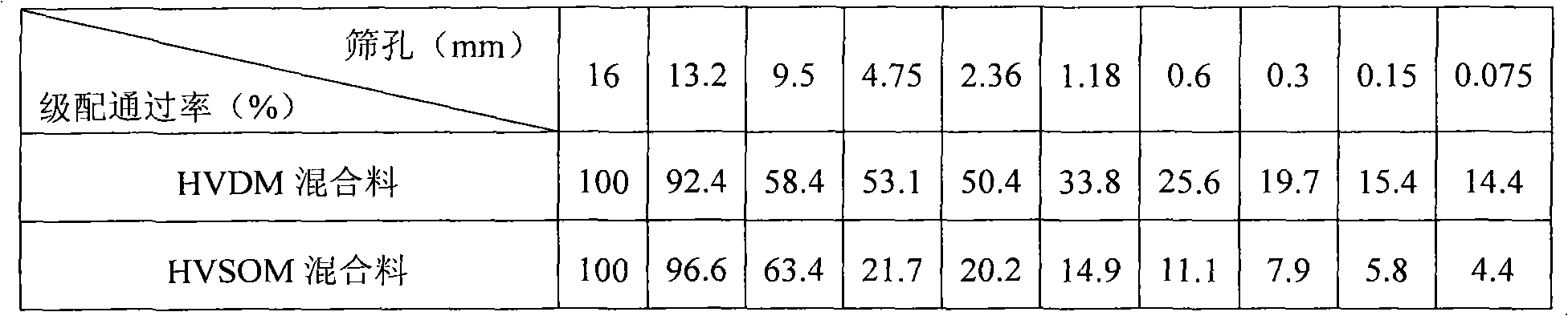

[0021] The aforementioned stress-absorbing composite structural layers are employed. The gradation of HVDM and HVSOM is shown in the table below.

[0022]

[0023] Use 90# base asphalt, add 10% additives, of which SBS is 55% of the additives. See the table below for the dosage of high viscosity modified asphalt and fiber. (accounting for mixture mass)

[0024] High Viscosity Modified Bitumen

lignin fiber

Amount added in HVDM (%)

9.6

0.3

/

Amount added in HVSOM (%)

5.8

0.1

0.2

[0025] In this example, the old cement slab has undergone grouting treatment, the thickness of HVDM is 2cm, the porosity is 2.5%, the thickness of HVSOM is 4cm, the porosity is 8.62%, and the waterproof wear layer is 4cm.

[0026] The overlay structure has been used in the test section and the feedback is good. A return visit after 1 year showed no reflection cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com