Continuous annealing process of deep drawing and extra-deep drawing steel plates

An annealing process and ultra-deep drawing technology, used in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of reducing the quality of home appliances and automobiles, low production efficiency, and poor furnace temperature uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The steel plate is cleaned before annealing, so that the content of rolling oil and iron powder on the surface of the steel plate is required to be less than 20mg / m 2 . The steel plate enters the continuous annealing furnace and walks at a speed of 150-350m / min, using H 2 Nitrogen-hydrogen mixed gas with a content of 3-5% is sprayed on the surface of the steel plate to protect the steel plate from oxidation, and at the same time heat the steel plate to 120-180°C.

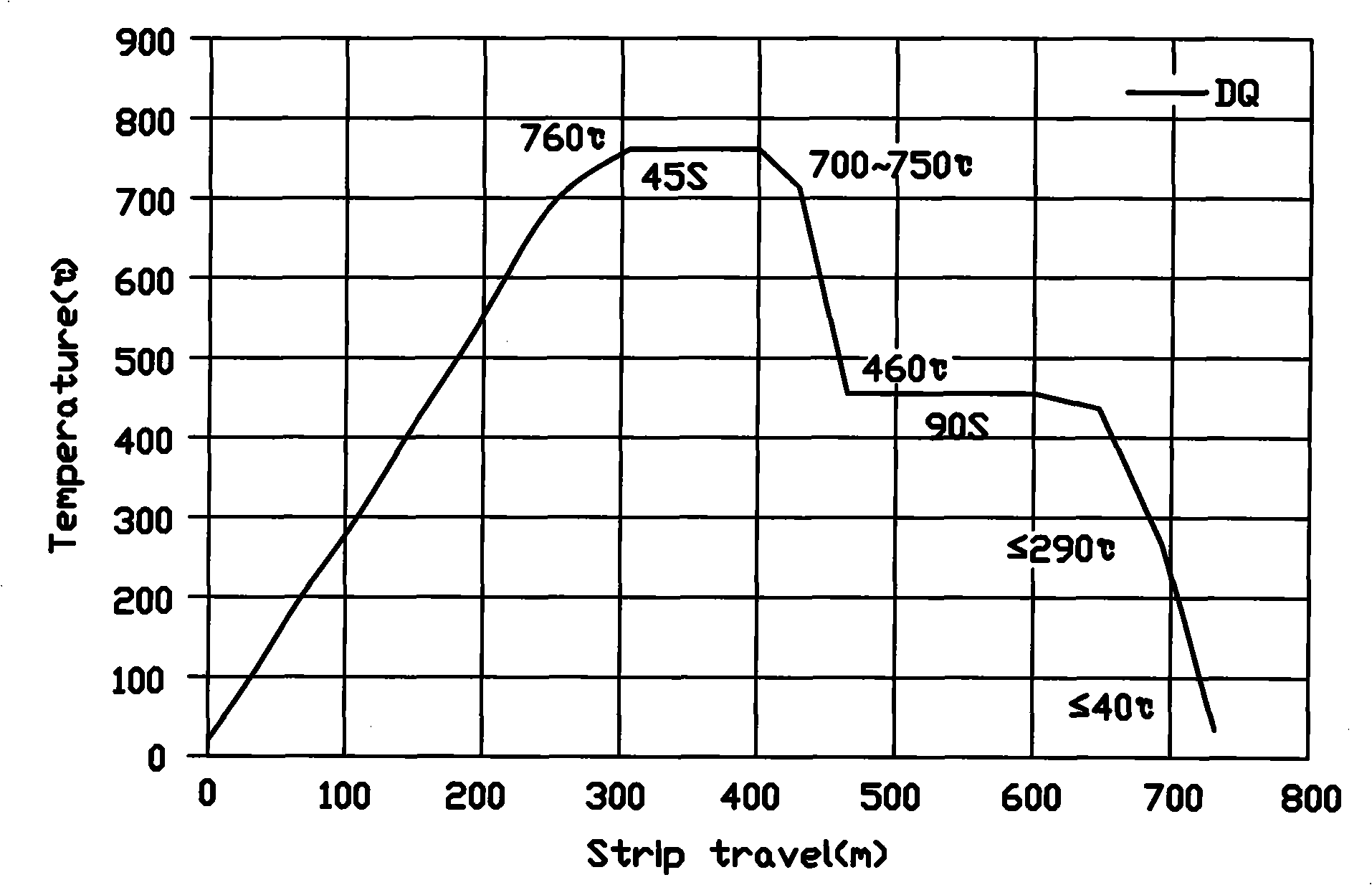

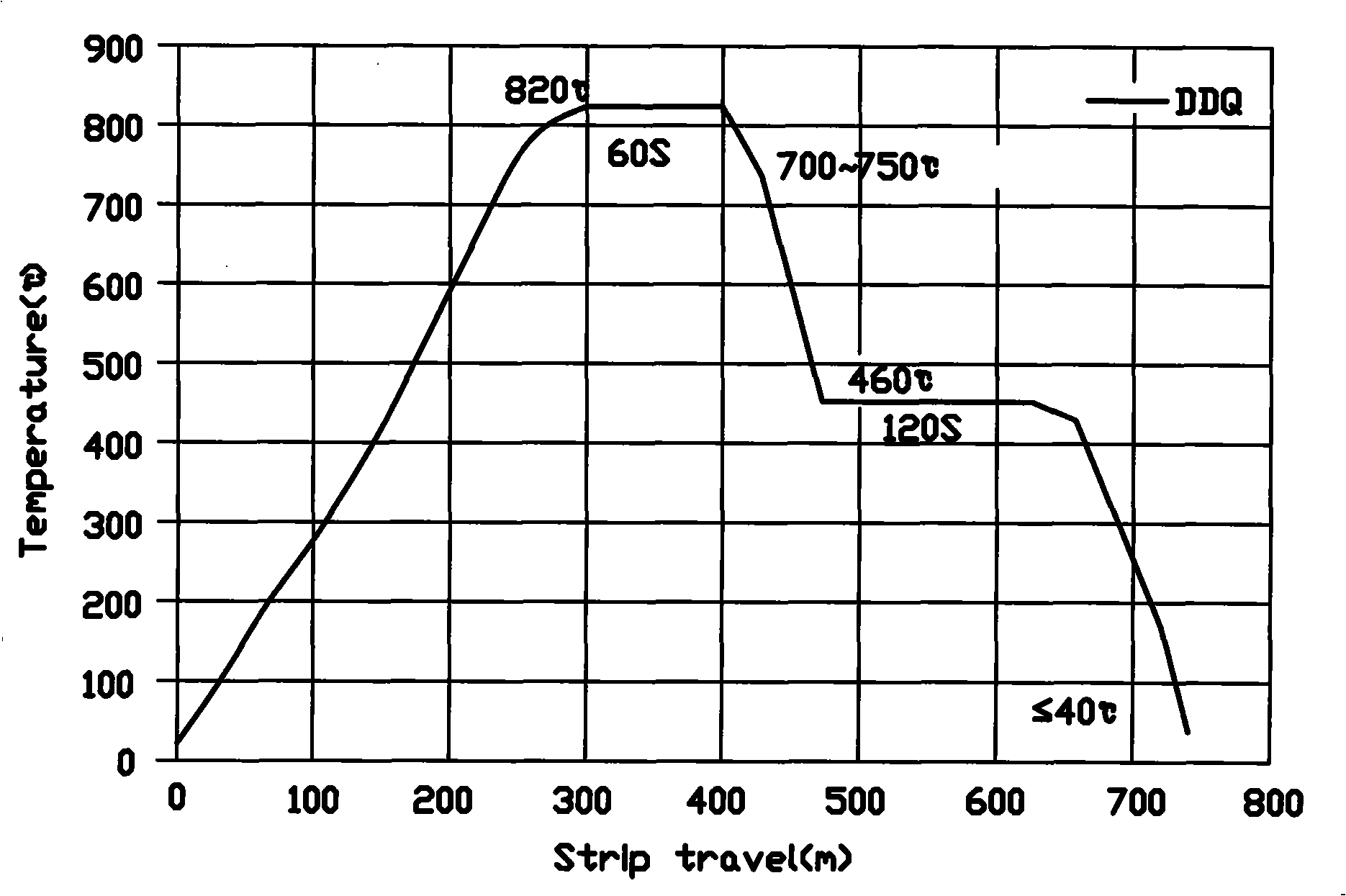

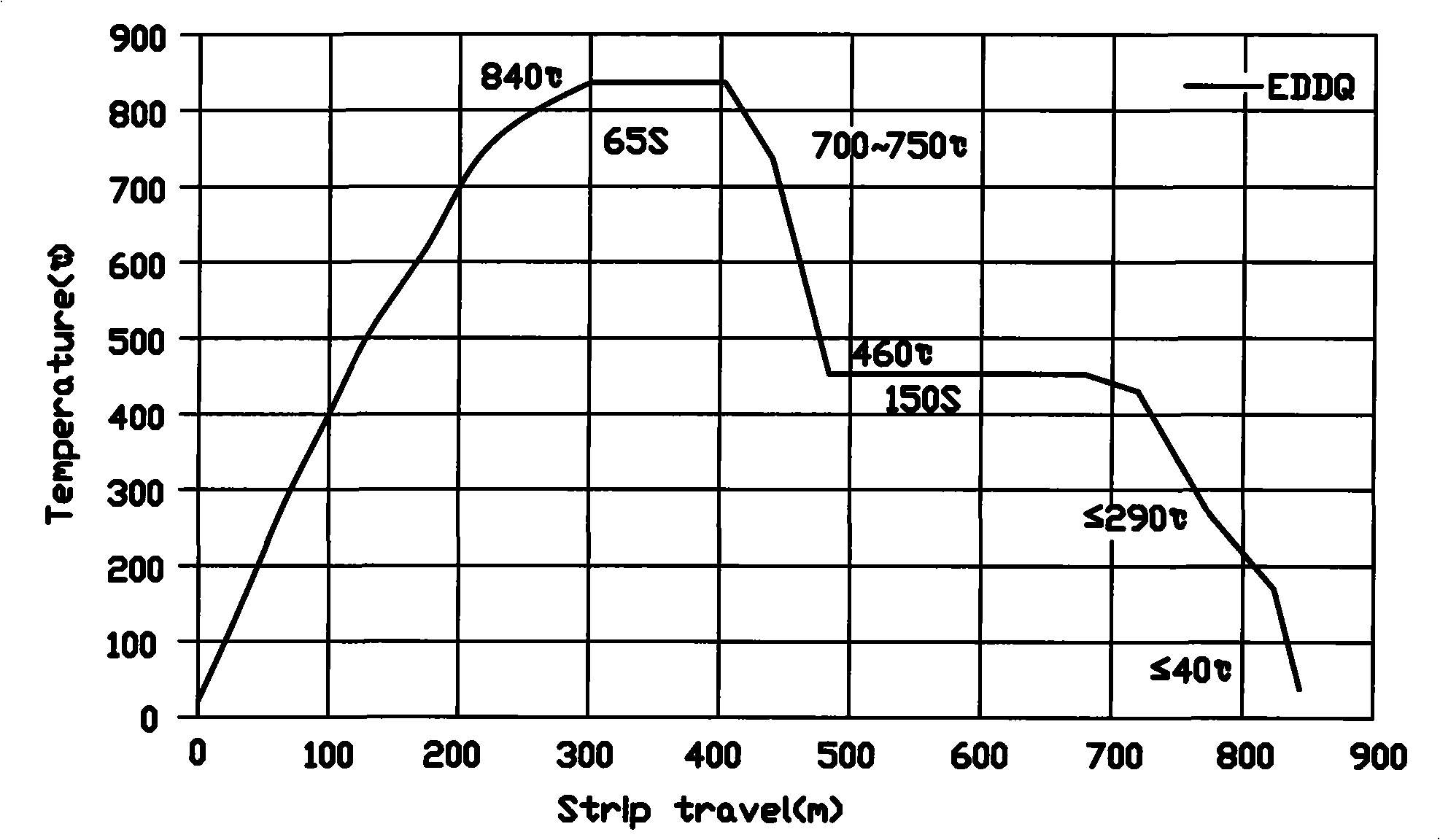

[0017] The steel plate heating temperature, holding time, overaging temperature and time generally vary according to the material grade. The steel plate heating temperature of different steel types is shown in the following table:

[0018]

steel type

(℃)

(S)

Overaging temperature

(℃)

aging time

(S)

DQ

760

45

400~460

90

DDQ-IF

820

60

400~460

120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com