Metal mixing device

A technology of mixing iron and iron mouth, applied in the field of metallurgical steelmaking accessories, can solve the problems of affecting the speed of the new baking furnace, preventing the evaporation of water, and wasting the energy of the baking furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

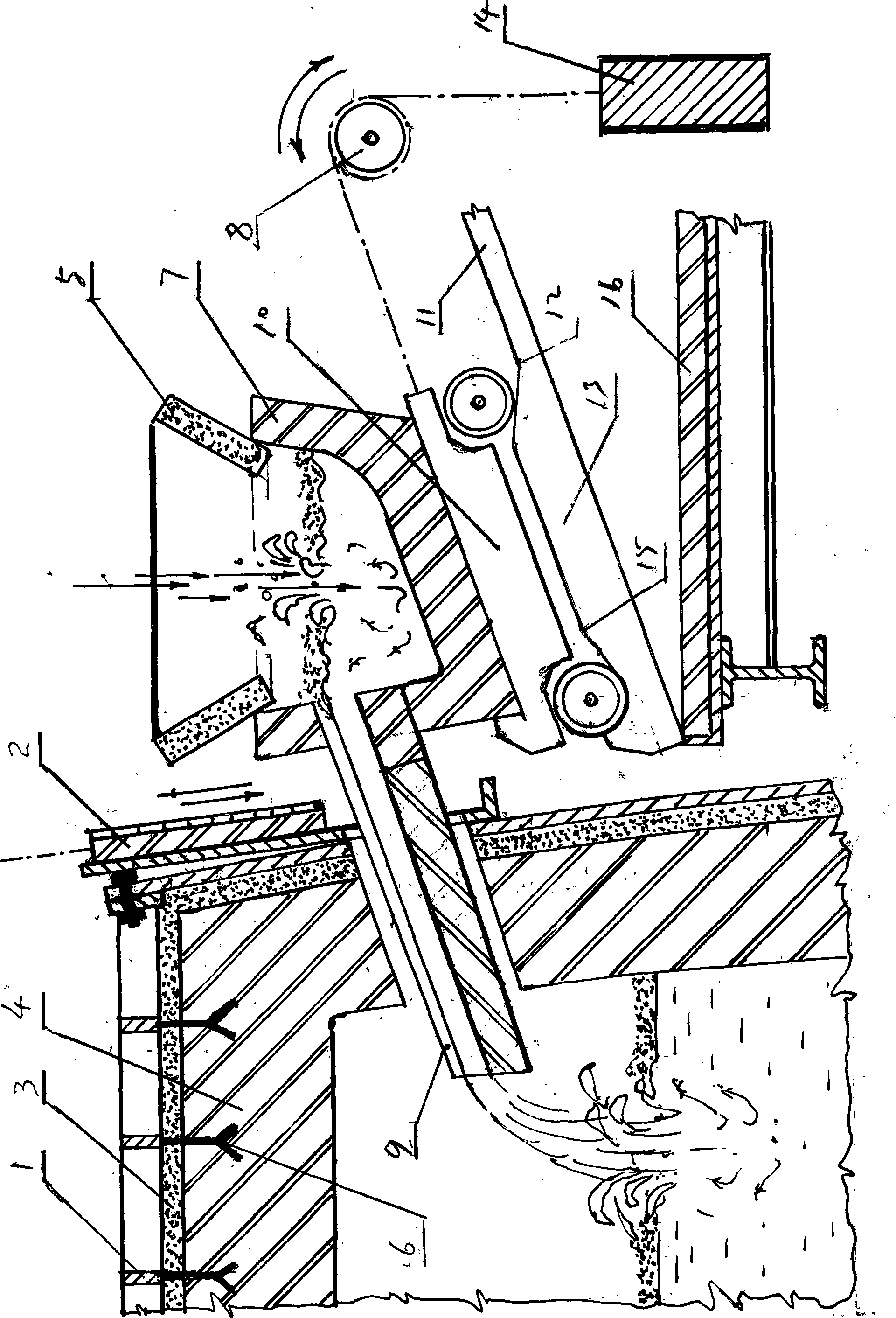

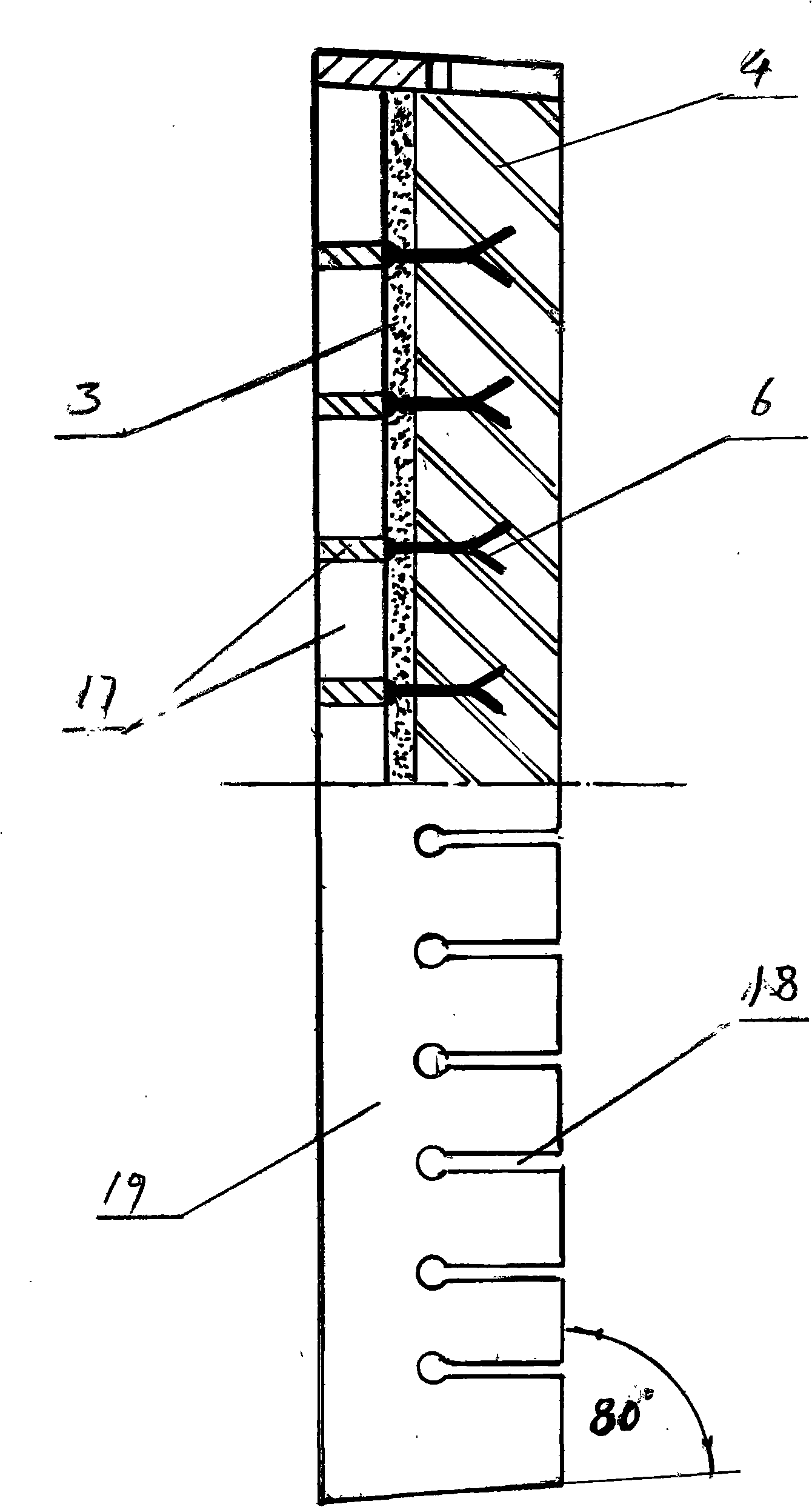

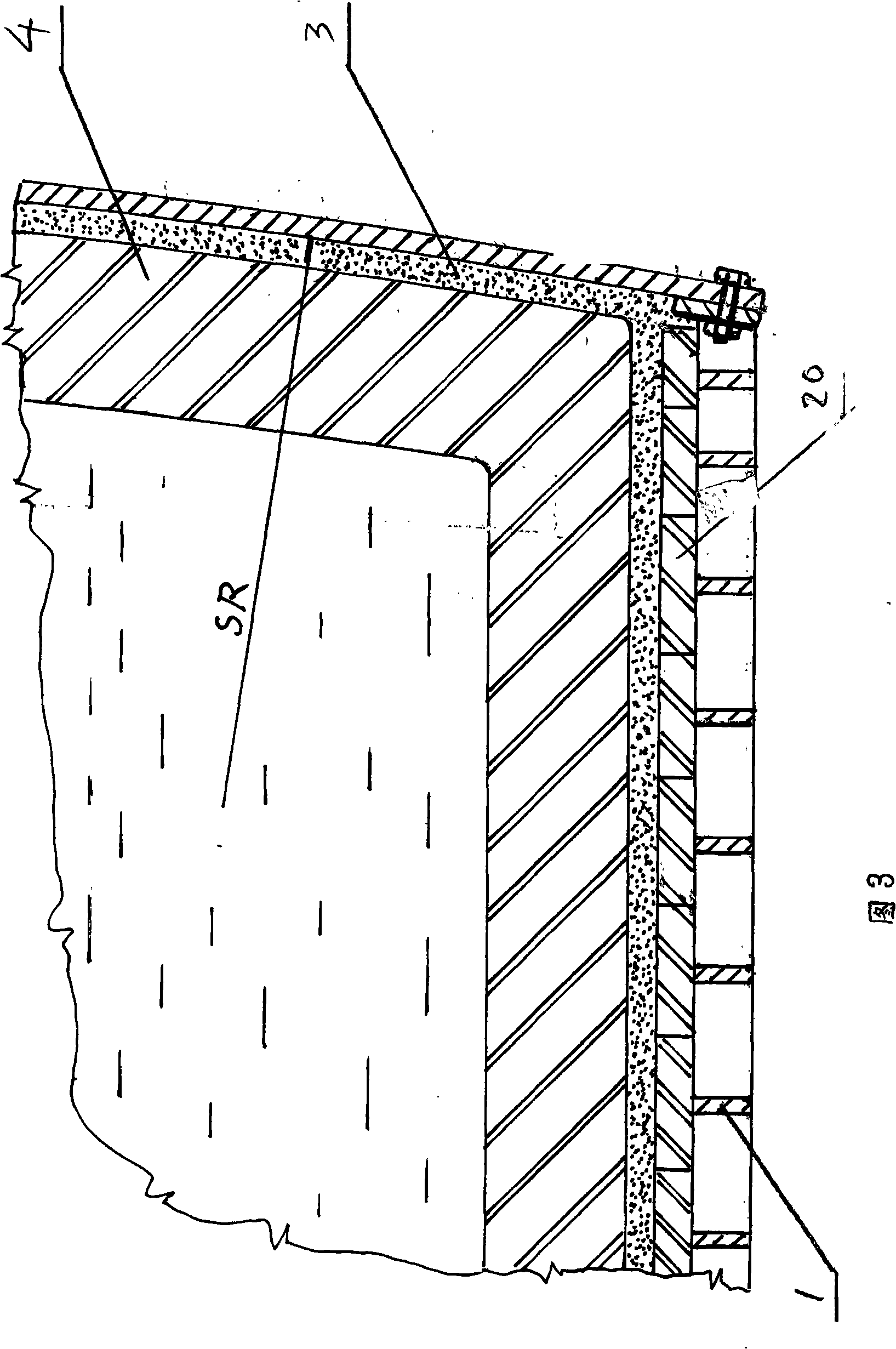

[0024] As shown in the figure, an iron mixing device is composed of an iron mixing furnace, an iron mixing tundish 7 and a tank car 10. The track 11 of the tank car 10 is arranged on the upper part of the track platform 16, and the track 11 is arranged obliquely. The track 11 gradually rises outward from the furnace body, the launder 9 of the iron mixing tundish 7 is parallel to the track 11, the cross-sectional size of the launder 9 matches the size of the iron mixing port of the iron mixing furnace, and the traction chain of the tank car 10 The tail portion of the tank car 10 is provided with a counterweight 14 equivalent in quality to the tank car 10, and the traction sprocket 8 of the tank car 10 is a forward and reverse sprocket wheel. The front portion of the track 11 is provided with a boss 13, the boss 13 has a transition section with the track at its rear, and the front end of the boss is provided with a front wheel spacer pit, and the starting point 12 of the transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com