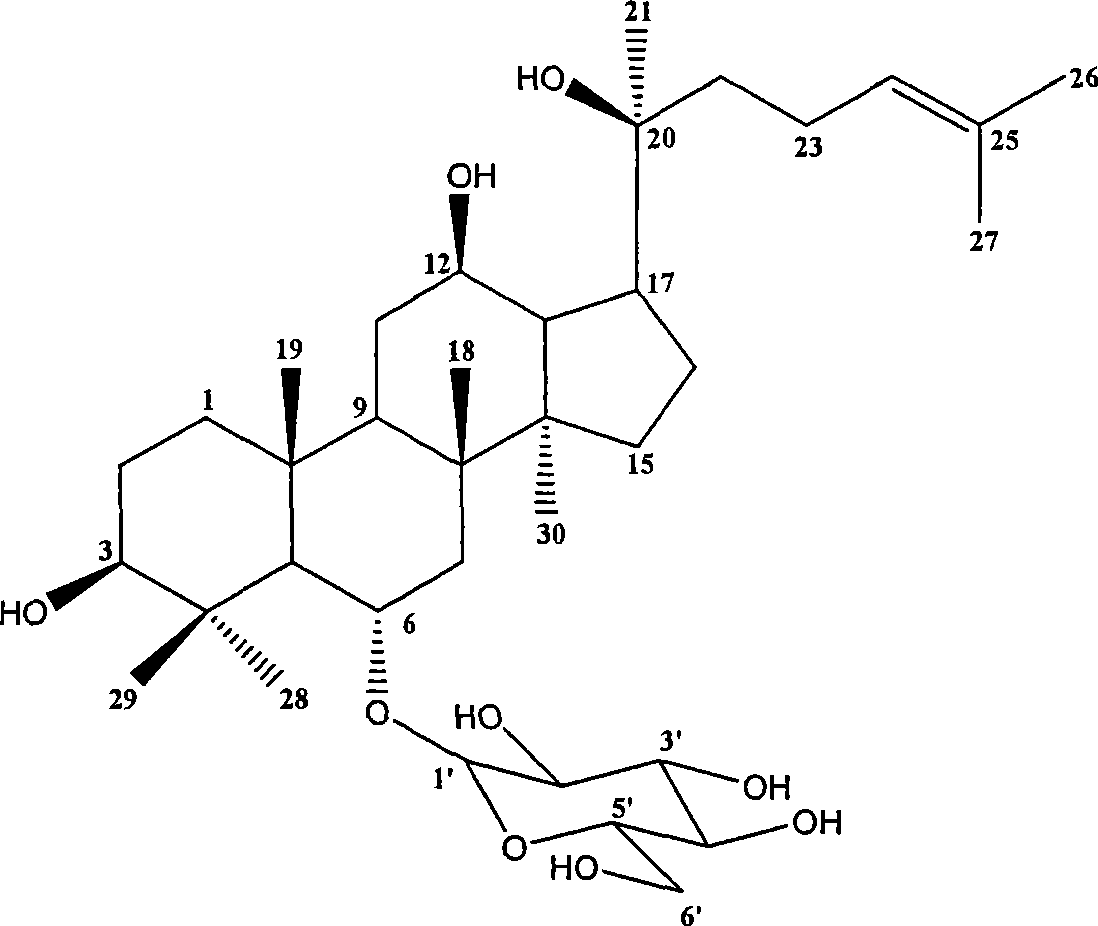

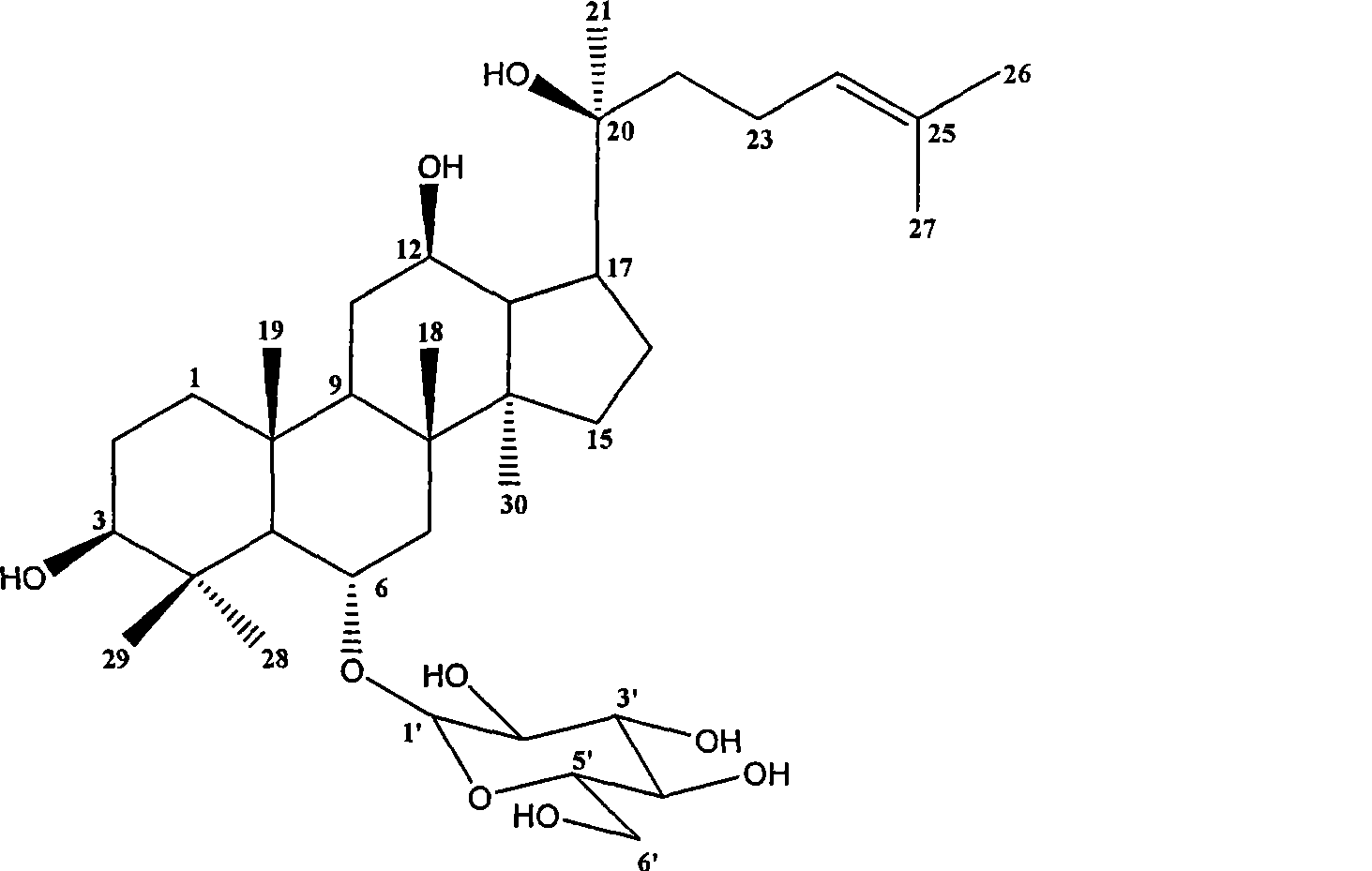

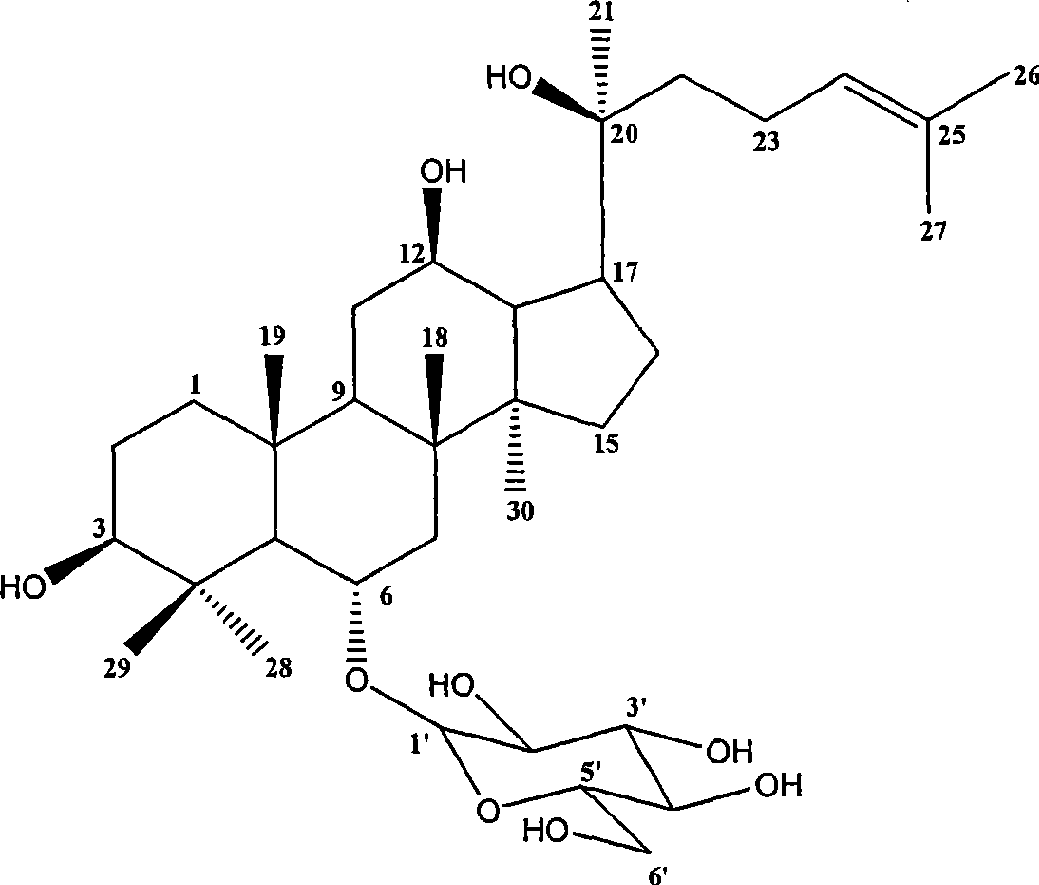

Process of preparing 20(S)-ginsenoside Rh1 with streptomycete fermentation of pseudo-ginseng saponin

A technology of notoginseng saponins and ginsenosides, which is applied in the fields of medicine and biology, and can solve problems such as high cost, high price, and inconvenient enzyme sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Streptomyces fradiae NTGA-334 was transferred from Gao Shi No. 1 slant to the ISP2 seed medium containing 1% (w / v) Panax notoginseng saponins, cultivated at 28°C for 12h; then inoculated into the seed medium containing 2500g In the 60L humic acid medium of Panax notoginseng saponins, the fermentation was carried out in a 100L fermenter at 28°C. After 36 hours, adjust and increase the ventilation ratio to 1:3 (v / v), and adjust the stirring rate to 400r / min. After 48 hours, adjust the fermentation temperature to 42°C, and dynamically adjust the pH to 5.0 with 5% (w / v) ammonia water. After 60 hours of fermentation, add Amberlite XAD~16 macroporous adsorption resin at 5% (w / v), stir for 2 hours, and put Can. The fermentation broth was filtered through a filter cloth to obtain a precipitate with a wet weight of 3912 g, which was ultrasonically extracted with 30 L of ethanol (95%) for 2 h and filtered through a filter cloth, and the filter residue was washed 5 times with 1 L...

Embodiment 2

[0018] Streptomyces fradiae NTGA-334 was transferred from Gao Shi No. 1 slant to the ISP2 medium medium containing 1% (w / v) panaxatriol group saponins, and cultivated at 28°C for 12h; then inoculated into In a 60L humic acid medium containing 1000g of panaxatriol group saponins, the fermentation was carried out in a 100L fermenter at 28°C. After 36 hours, adjust and increase the ventilation ratio to 1:2, and adjust the stirring rate to 350r / min. After 48 hours, adjust the fermentation temperature to 38°C, and dynamically adjust the pH to 5.0 with 5% (w / v) ammonia water. After 60 hours of fermentation, add Amberlite XAD~16 macroporous adsorption resin at 1% (w / v), stir for 4 hours, and put Can. The fermentation broth was filtered through a filter cloth to obtain a precipitate with a wet weight of 2023 g, which was ultrasonically extracted with 20 L of ethanol (95%) for 2 h and filtered through a filter cloth, and the filter residue was washed 5 times with 1 L of ethanol (95%)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com