Preparation method of liposome

A technology of liposomes and spheres, which is applied in the direction of liposome delivery, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., which can solve the problems of inability to increase the thickness of lipid film, low feasibility, limitations, etc. problems, to achieve the effects of low manufacturing cost, wide applicability, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

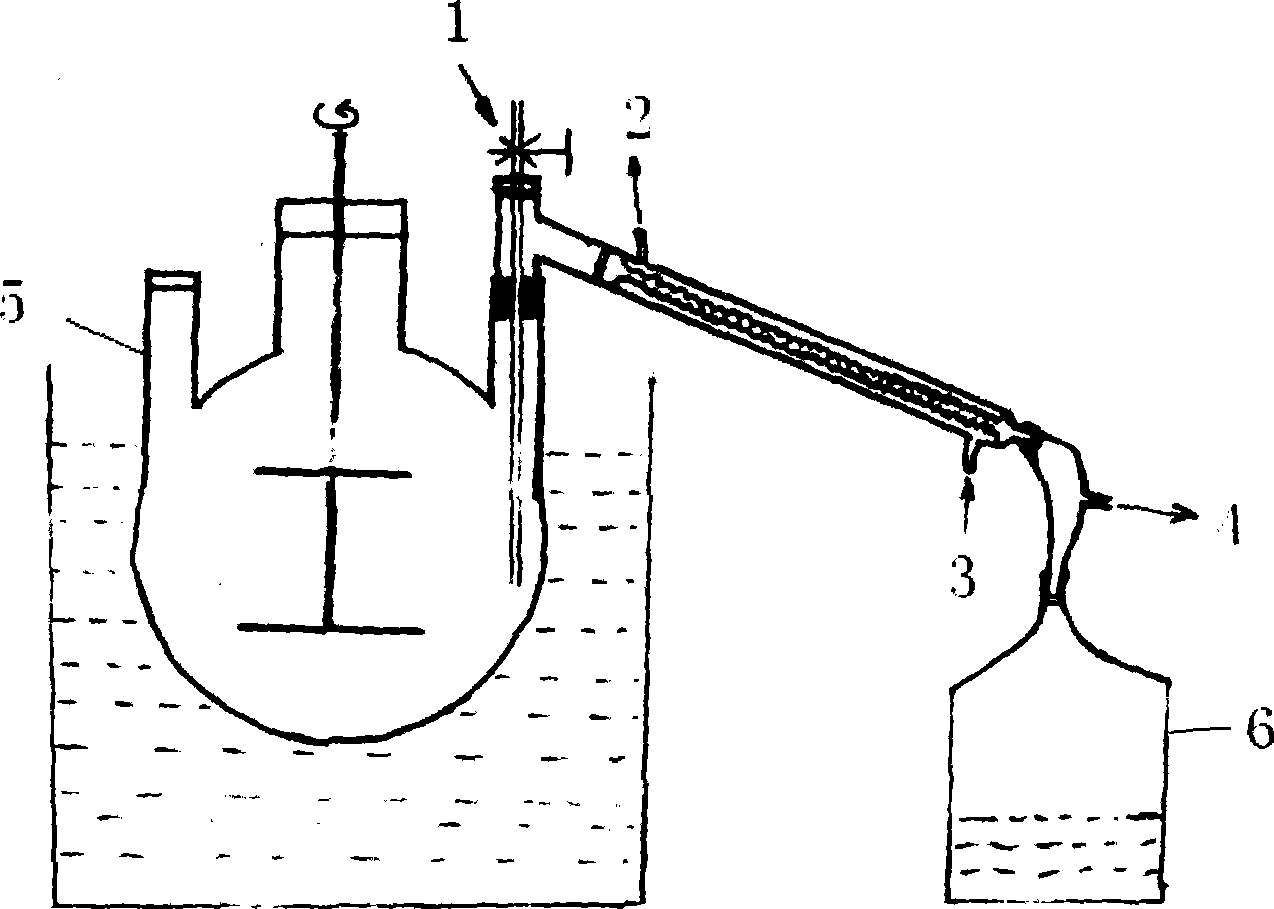

[0035] The preparation steps of liposome of the present invention are:

[0036] Step 1: Put the organic solvent into a container that meets the pharmaceutical requirements,

[0037] Step 2: adding film-forming material and fat-soluble drug to the container,

[0038] Step 3: stirring or heating under reflux to fully dissolve the contents of the container,

[0039] Step 4: Put the microbeads into the above container,

[0040] Step 5: Rotate, heat the container in a water bath and evacuate, evaporate and remove the organic solvent,

[0041] A layer of lipid film is formed on the inner wall of the container and the surface of the microbeads,

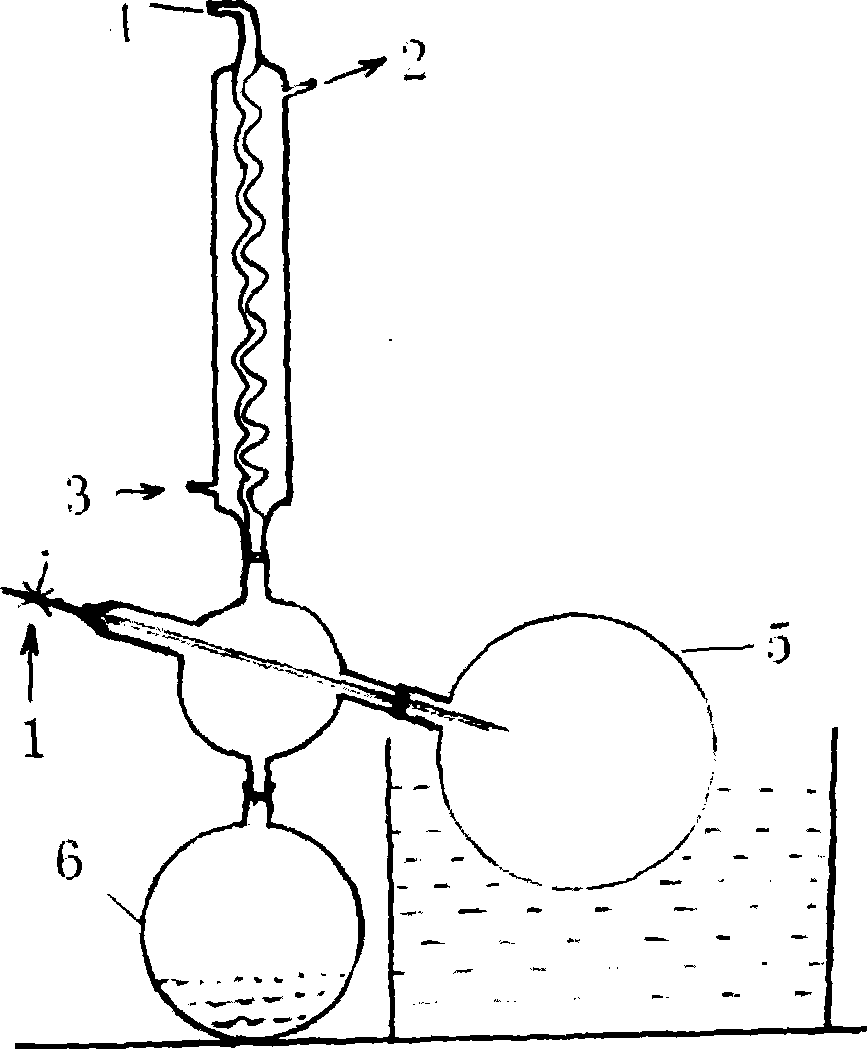

[0042] Step 6: further drying the formed lipid film,

[0043] Step 7: Add the water phase or the water phase containing the drug, so that the lipid film forms liposomes from the inner wall of the container and

[0044] The surface of the microbeads falls off.

[0045] On the basis of the above scheme, said step 2 can also be: adding fi...

Embodiment 1

[0054] Embodiment 1 - the preparation of dexamethasone acetate liposome

[0055]Take 0.65g of egg yolk phospholipids, 0.125g of cholesterol, 20mg of dexamethasone acetate, and 30mg of vitamin E in a 250ml round bottom flask, dissolve them in 100ml of ethanol, add glass beads with a diameter of 3mm, vacuum at 11KPa, temperature at 46°C, and rotate at 30rpm Evaporate for 30 minutes to remove the organic solvent, and a layer of lipid film is formed on the surface of the microbeads. Put the flask into a vacuum dryer or blow hot air into the flask to further dry the lipid film, and add pH7.38 phosphate containing sodium sulfite to the flask Buffer solution, rotate or shake the flask, the lipid dry film will soon form a milky white liposome liquid, and there is no sediment and suspended matter in the emulsion.

[0056] Take the liposome liquid prepared above, add it into molten polyethylene glycol 6000 according to the weight ratio of 1:1.5, mix evenly, and then the dropping pill ca...

Embodiment 2

[0057] Embodiment 2 - the preparation of vitamin E liposome

[0058] Take 0.65g of egg yolk phospholipids, 0.125g of cholesterol, and 58mg of hydroquinone in a 250ml round bottom flask, dissolve them in 100ml of dichloromethane, add glass beads with a diameter of 2mm, vacuum at 12KPa, temperature at 35°C, and 50rpm rotary evaporation for 32 minutes Remove the organic solvent and form a layer of lipid film on the surface of the microbeads. Put the flask into a vacuum dryer or blow hot air into the flask to further dry the lipid film. Add pH7.42 boric acid containing sodium bisulfite to the flask Salt buffer solution, rotating or shaking the flask, the lipid dry film will soon form a milky white liposome liquid, and there is no sediment and suspended matter in the emulsion. The prepared vitamin E liposome liquid can be used as skin care liquid or cosmetics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com