Roller equipment with sectionally independent air intake and air discharge

A drum equipment and drum technology are applied in the fields of tobacco preparation, application, tobacco, etc., and can solve the problems such as inability to control temperature in sections, inability to effectively adjust and control tobacco processing process indicators, and inability to achieve independent speed regulation in sections, etc. The effect of tobacco smoking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

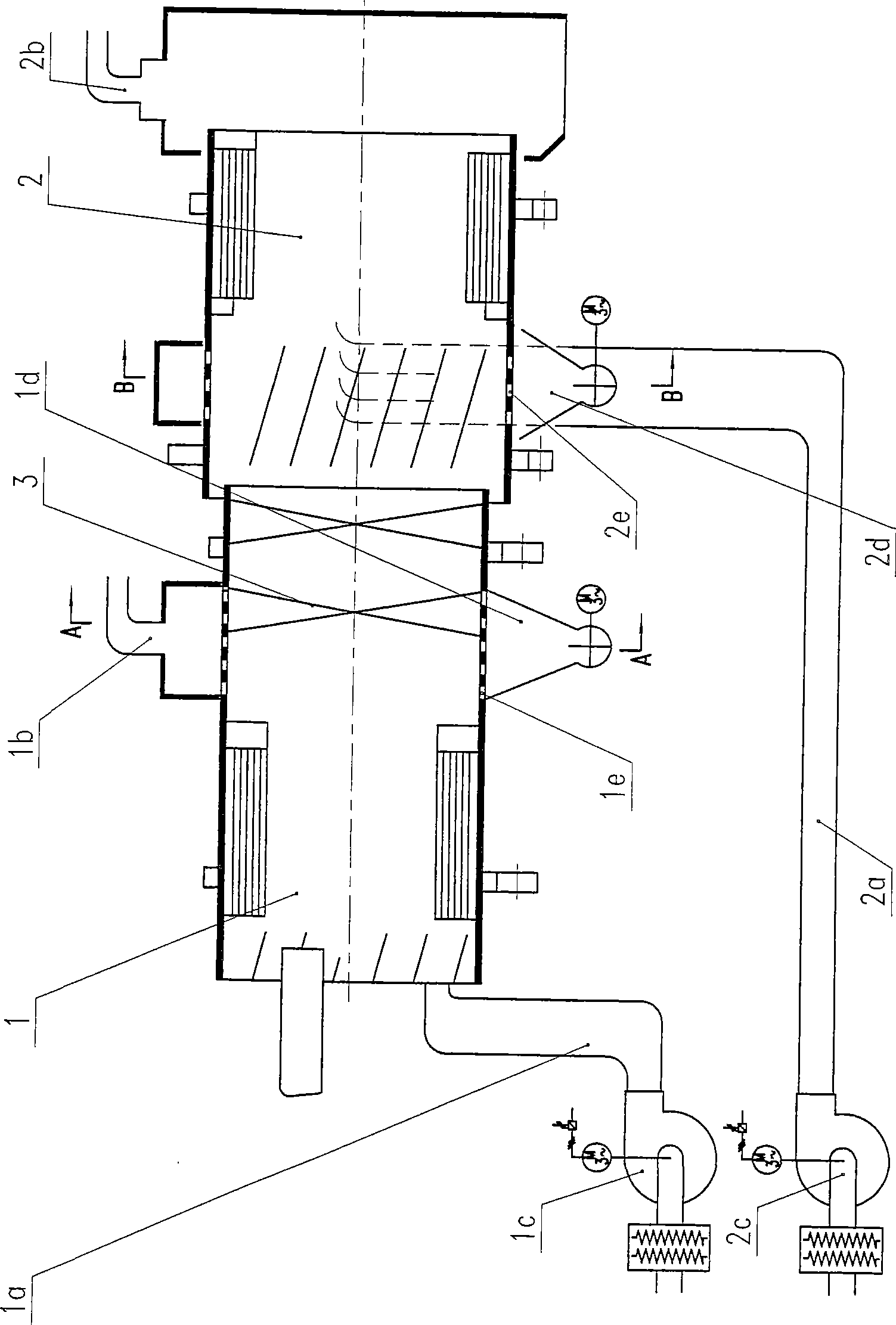

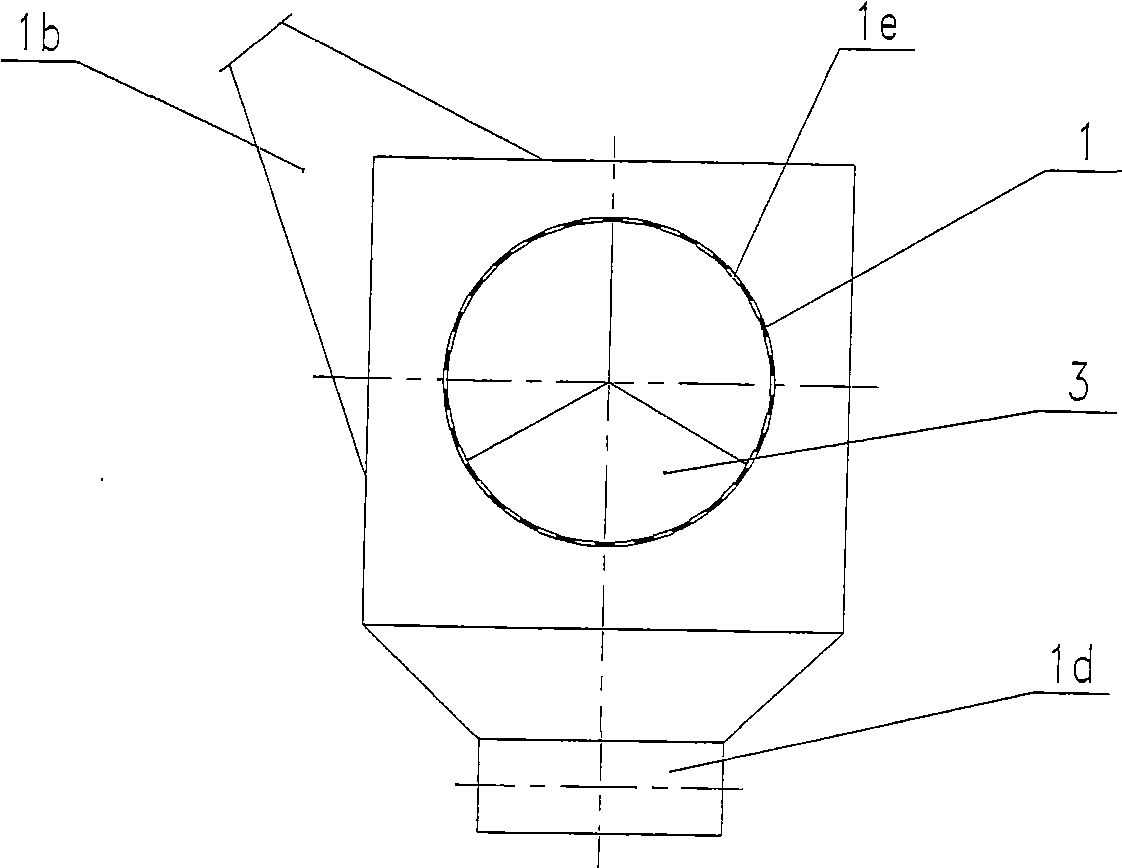

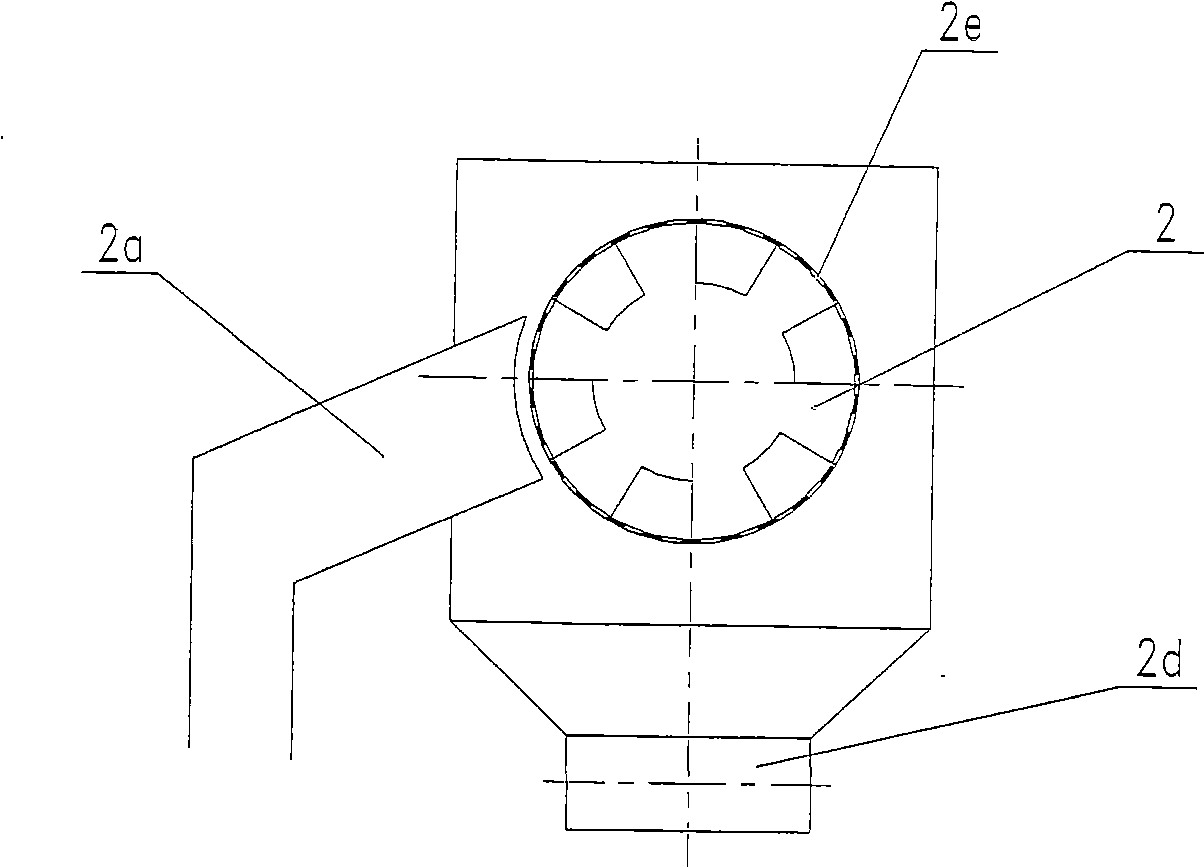

[0013] As shown in the figure, the drum of the present invention is composed of two or more drums connected to each other. In this embodiment, there are two drums, that is, drum 1 and drum 2, and each drum is provided with an independent air inlet pipe. 1a, 2a and the air outlet pipes 1b, 2b are provided with a wind shield 3 between each connected two-section drum. One end of the air inlet pipe 1a of the drum 1 is connected to the fan 1c, and the other end leads into the feed end of the drum 1, and the air outlet pipe 1b is arranged above the tail of the drum 1. One end of the air inlet pipe 2a of the drum 2 is connected to the side of the drum, the other end is connected to the fan 2c, and the air outlet pipe 2b is arranged on the top of the drum 2 . The wind-shielding plate 3 can be a helical blade or an inclined blade, and the helical blade is selected in this embodiment. Ash discharge hoppers 1d and 2d are respectively arranged at the bottom of each section of the drum. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com