Process for producing polarizer, polarizer, polarizing plate, optical film, process for producing composite polarizing plate, composite polarizing plate, and image display device

一种图像显示装置、制造方法的技术,应用在光学、光学元件、偏振元件等方向,能够解决制造装置大型化、复杂结构、PVA薄膜结构困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0134] (Preparation of PVA film)

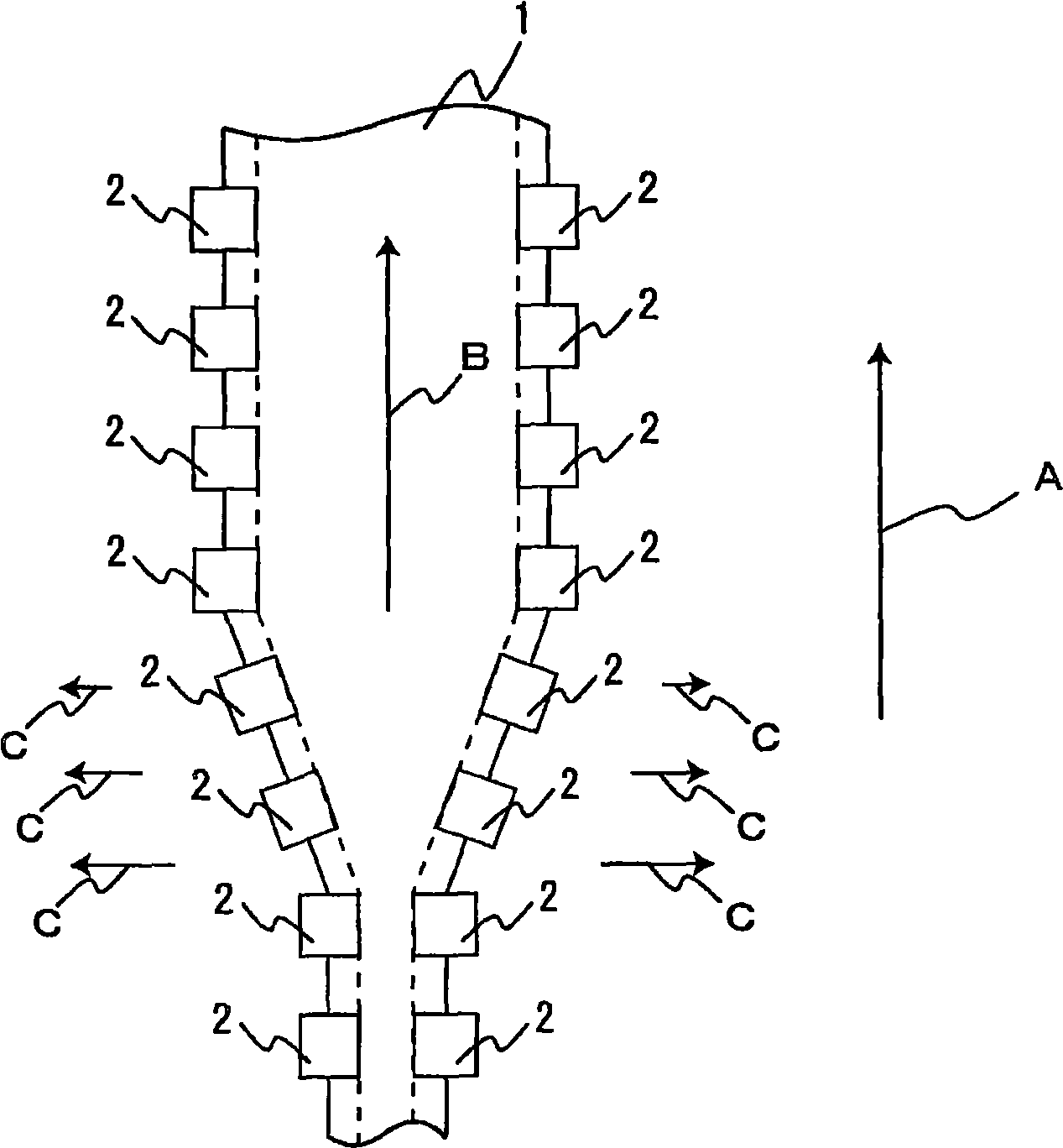

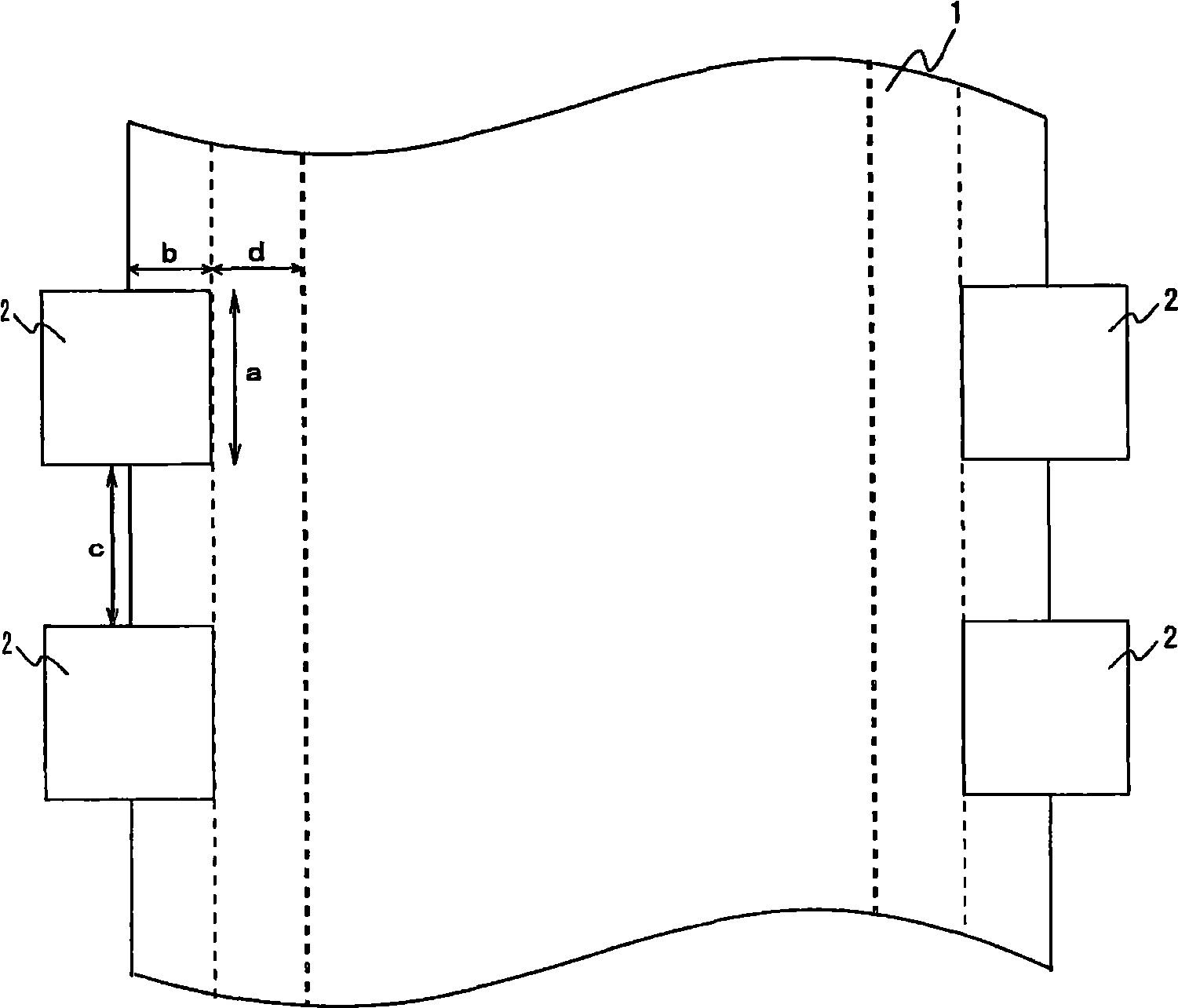

[0135] A raw material PVA film (manufactured by Kurary Co., Ltd., trade name: "VF-PS") was prepared. The thickness of the PVA film was 75 μm. Using a tenter stretching machine, both ends in the width direction of the PVA film were held by tenter clips (holding mechanism), and the PVA film was conveyed in its longitudinal direction, and the following steps were carried out. The length of the holding region of the tenter clips (holding mechanism) was set to 14 mm, and the width was set to 19 mm. In addition, the distance between the tenter clips (holding mechanisms) adjacent to each other in the longitudinal direction of the PVA film was set to 10 mm.

[0136] (production of polarizer)

[0137] (1) Swelling process

[0138] One surface of the PVA film was sprayed with water (swelling liquid) at room temperature (23° C.) for 30 seconds in a gas phase. At this time, assuming that there is a line connecting the ends of tenter clips (holding m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com