Method for producing high multilayered blind hole multilayer board by double head pressing insertion pin

A multi-layer board and high multi-layer technology is applied in the direction of multi-layer circuit manufacturing and electrical connection formation of printed components. It can solve problems such as poor hole wall quality, difficulty in chip removal, and decreased electroplating efficiency, so as to solve protection problems and manufacture The effect of process optimization and reduction of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

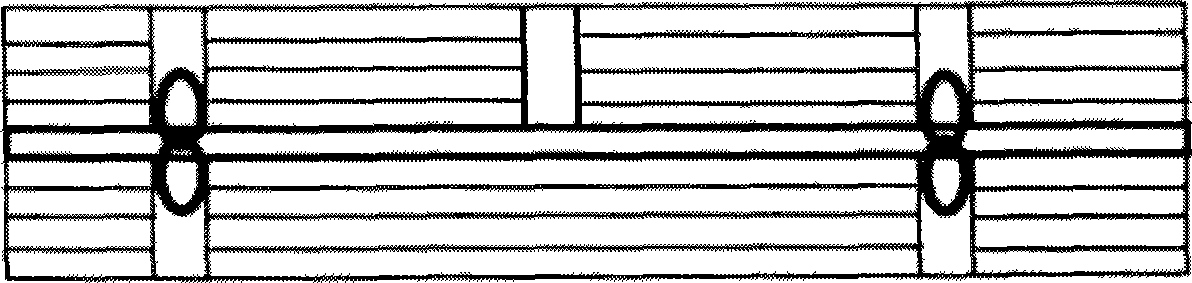

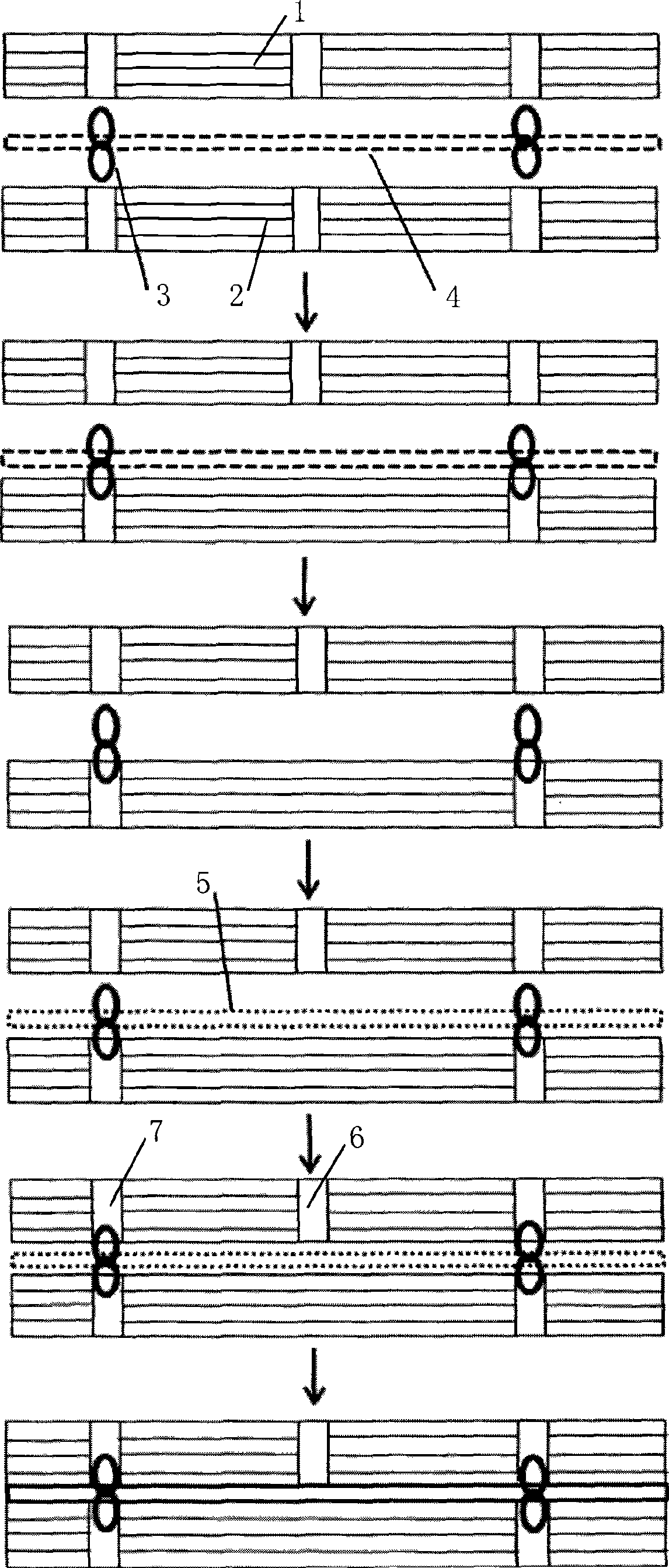

[0014] like image 3 As shown in the figure, the method of making high-level multi-layer blind-hole multilayer boards by double-headed crimping pins is to divide a backplane into several sub-boards. After the sub-boards are fabricated through drilling, electroplating and surface treatment, Then, the upper and lower sub-boards are crimped to the upper and lower sub-boards through the double-ended pressing pins 3, and then lamination and pressing are carried out to finally form the mother board. The other holes without pressing pins become blind holes. After pressing, the board can be used directly without wet treatment.

[0015] Using double-ended press pins, first put the tool board 4 (such as image 3 shown) drilling, only drill through hole 7 when drilling, do not drill blind hole 6, insert the double-ended press pin 3 into the tool 4 board, and press the double-ended press insert on the tool board 4 through the cooperation of the positioning holes Press one end of pin 3 int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com