Electrical distribution box bus bar and insulation supporting protection system

A technology of insulating support and protection system, which is applied in the direction of busbar/line layout and open busbar installation, etc. It can solve the problems of poor support effect, potential safety hazards in use, poor insulation performance, etc., and achieves compact structure, high safety, and insulation good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

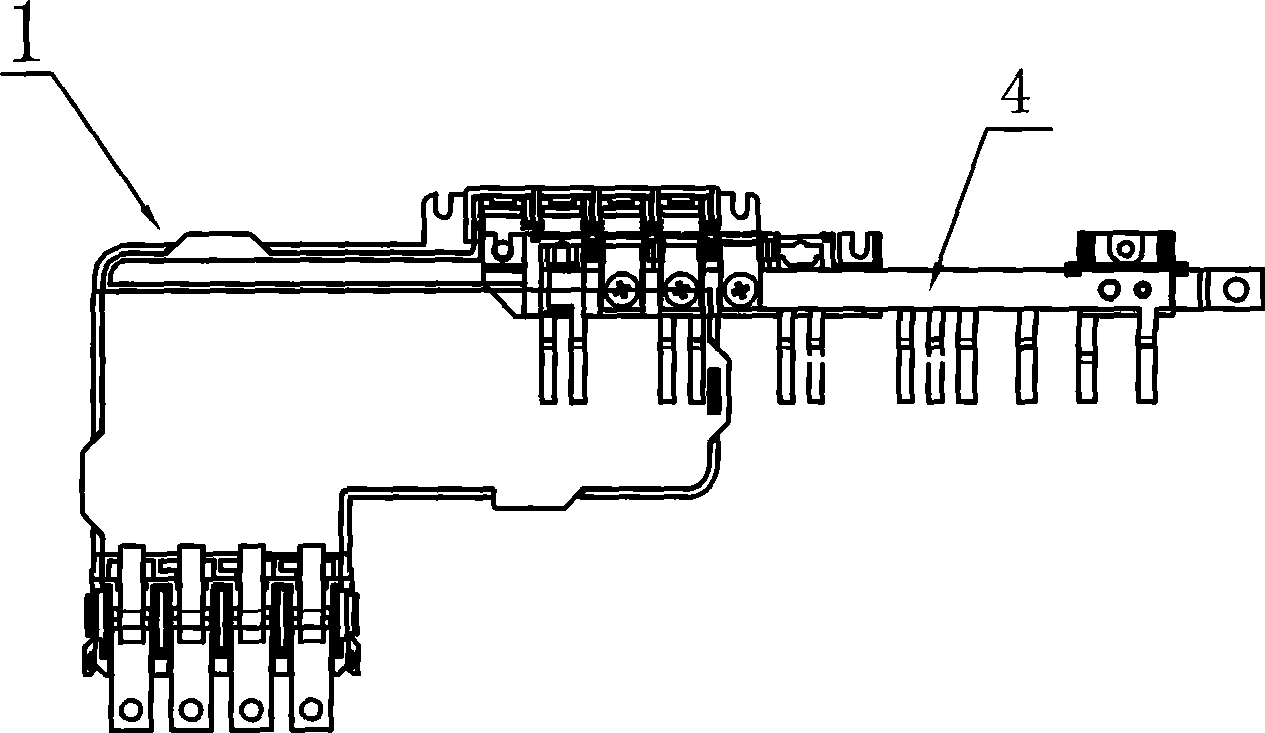

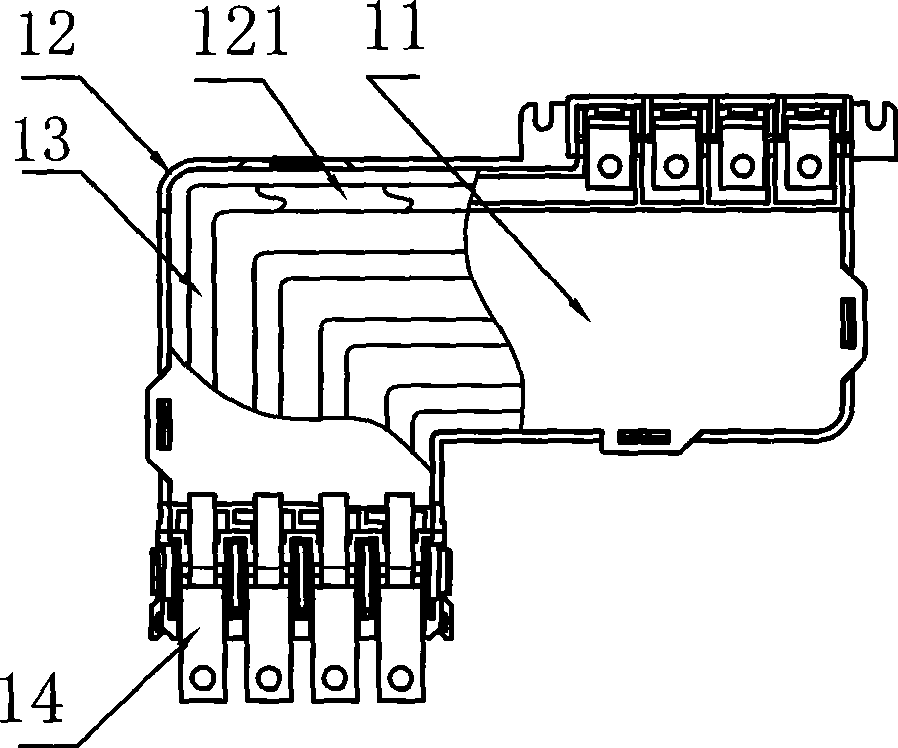

[0017] Embodiment 1: The distribution box busbar and insulation support protection system described in this embodiment include a transfer busbar module group 1 and a single-row branch busbar module group 4, wherein the transfer busbar module group 1 includes transfer Busbar protective cover base 11, transfer busbar protective cover bottom cover 12, transfer busbar 13, outgoing busbar 14, use card between transfer busbar protective cover base 11 and transfer busbar protective cover bottom cover 12 The hook-and-catch slot structures are interconnected to form an adapter busbar shield, and four busbar grooves 121 are arranged on the inner surface of the adapter busbar shield bottom cover 12, and the adapter busbars 13 are installed in each busbar groove in turn. In 121, screw holes are provided at both ends of each transfer busbar 13 for connecting with other parts. In the branch busbar module group 4, the rear ends of each transfer busbar 13 are respectively connected with outle...

Embodiment 2

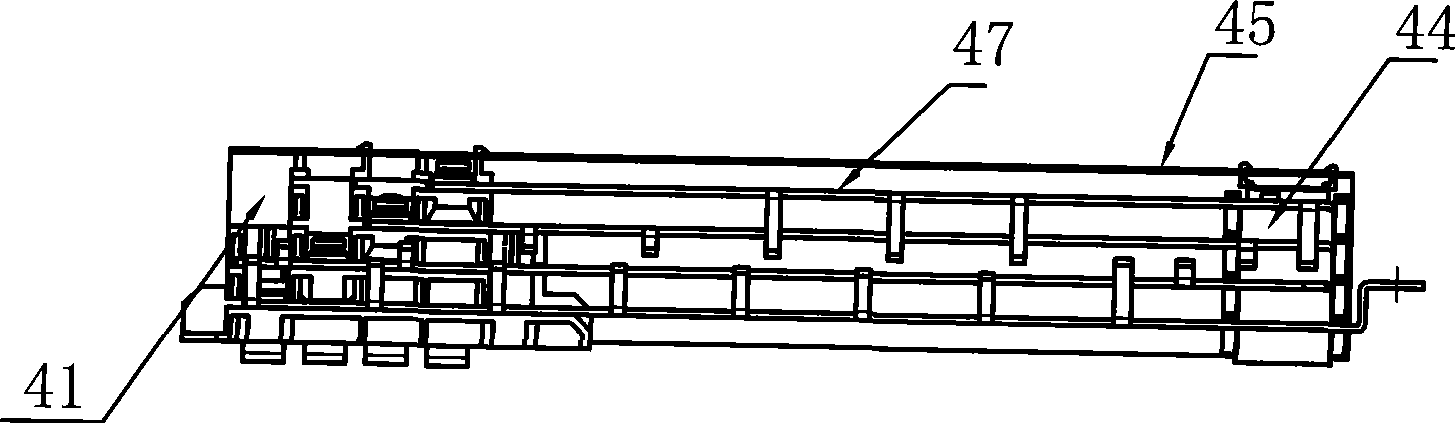

[0018] Embodiment 2: The distribution box busbar and insulation support protection system described in this embodiment is based on the technical solution described in Embodiment 1. A second branch busbar module group 4 is added and used to connect the branch The short confluence busbar module group 2 of the busbar module group 4, wherein the short confluence busbar module group 2 includes a busbar fixing seat 21, a busbar fixing groove 22, and a protective cover box 23, and the upper surface of the busbar fixing seat 21 is provided with Four busbar slots 213, the bottom of each busbar slot 213 is provided with a blind hole 214 for receiving the screws connected to the busbar, the front end of the busbar fixing seat 21 is connected to the rear end of the transfer busbar protective cover bottom cover 12 through an elastic clip , each busbar groove 213 is aligned with the busbar groove 121 on the bottom cover 12 of the transfer busbar protective cover, and the two sides of the bus...

Embodiment 3

[0019] Embodiment 3: The distribution box busbar and insulation support protection system described in this embodiment is based on the technical solution described in Embodiment 2. A third branch busbar module group 4 is added and used to connect the branch The long confluence busbar module group 3 of the busbar module group 4, wherein the long confluence busbar module group 3 includes two busbar protection grooves 31 connected end to end, a confluence busbar 32 and a busbar fixing groove 22, the busbar in this embodiment The protective slot 31 is composed of two interlocking slot plates. Four busbar slots 311 are arranged on the inside of each slot plate, and the four busbars 32 are installed in the four busbar slots 311 respectively. The card is connected to the rear end of the short confluence busbar module group 2, each busbar groove 311 is aligned with the busbar groove 223 on the busbar fixing seat 21, and the front ends of the four confluence busbars 32 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com