Atomizing chilling and fractional condensing process and apparatus used for biomass, coal or oil shale pyrolysis and liquefaction

A technology of graded condensation and oil shale, applied in the directions of liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of pyrolysis steam quenching, slow cooling speed, and liquid polycondensation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

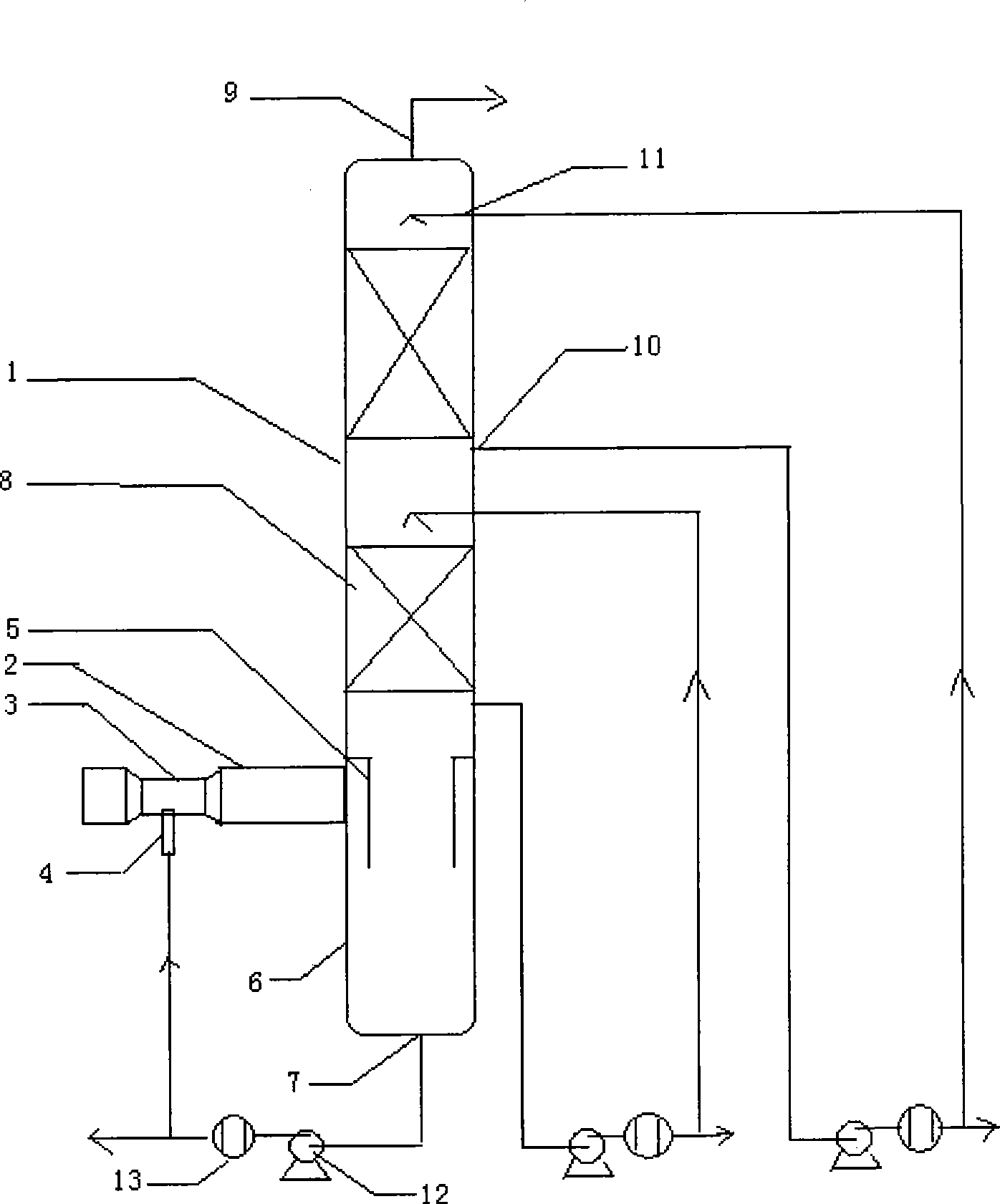

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings: the spray quenching and staged condensation process and device for the pyrolysis and liquefaction of biomass, coal or oil shale described in the present invention are heavy liquid cooling backflow through the quenching oil atomization nozzle (4) From the venturi throat (3) spray into the high-temperature pyrolysis gas flowing through the Venturi type into the tower tube (2), the oil mist and the pyrolysis gas are fully contacted and quenched, so that the temperature of the oil and gas is low At 300°C, it enters the graded condensation tower (1) at high speed along the tangential direction; the oil and gas are centrifugally separated by the cyclone drum (5), and the heavy liquid flows downward into the bottom section of the tower (6) and flows out from the heavy liquid outlet (7) and Pressurized by the oil pump (12) and cooled by the heat exchanger (13), part of the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com