Controllable liquid injection pipe and controllable liquid injection method convenient for downhole and uplifting

A liquid injection pipe and liquid injection technology, which is applied in the direction of earthwork drilling, wellbore/well components, and production fluids, etc., can solve the problems of reducing the lifting speed, increasing the outer diameter of the bladder, and low discharge speed, so as to increase the lifting speed , Eliminate the effect of skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 Controllable Liquid Injection Pipe Structure

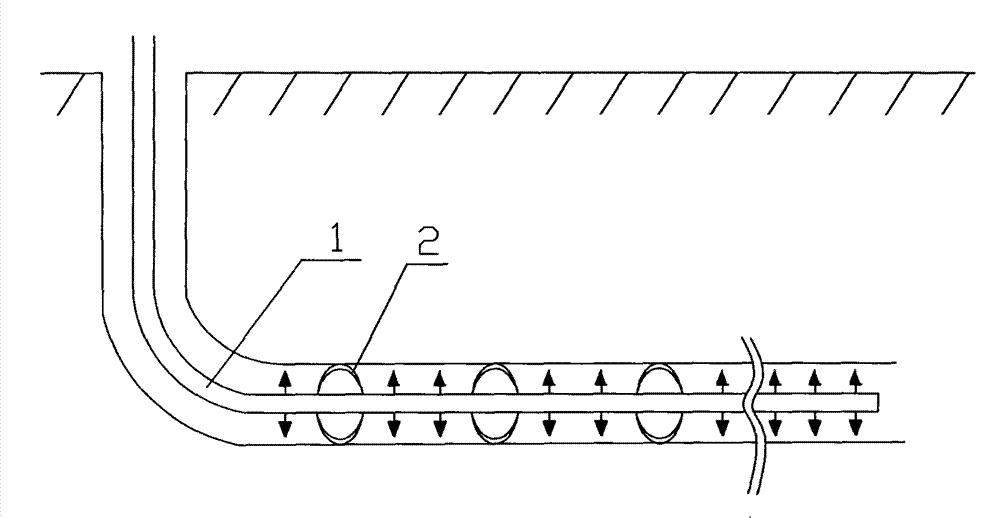

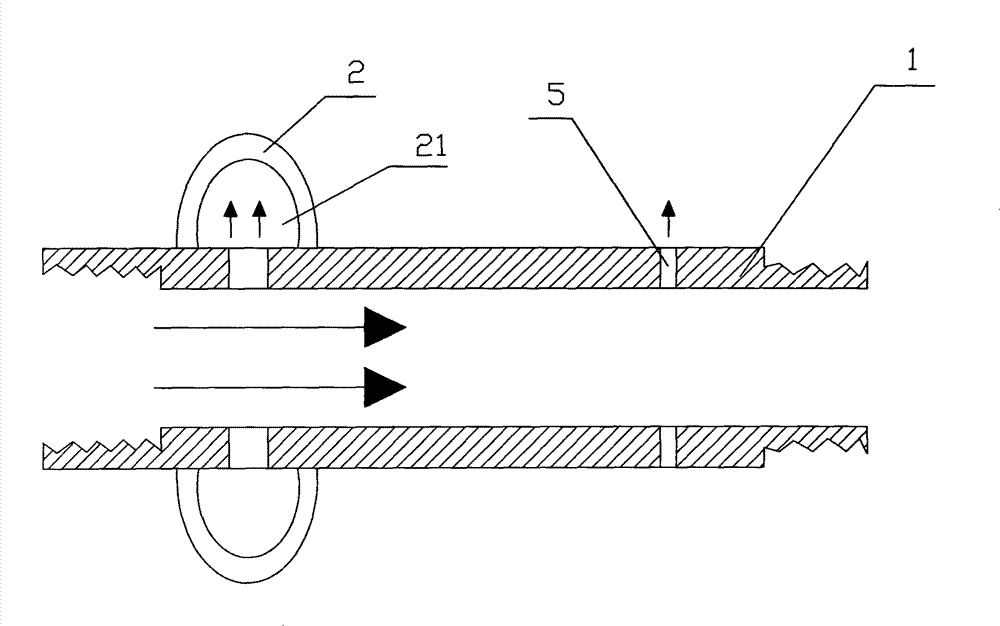

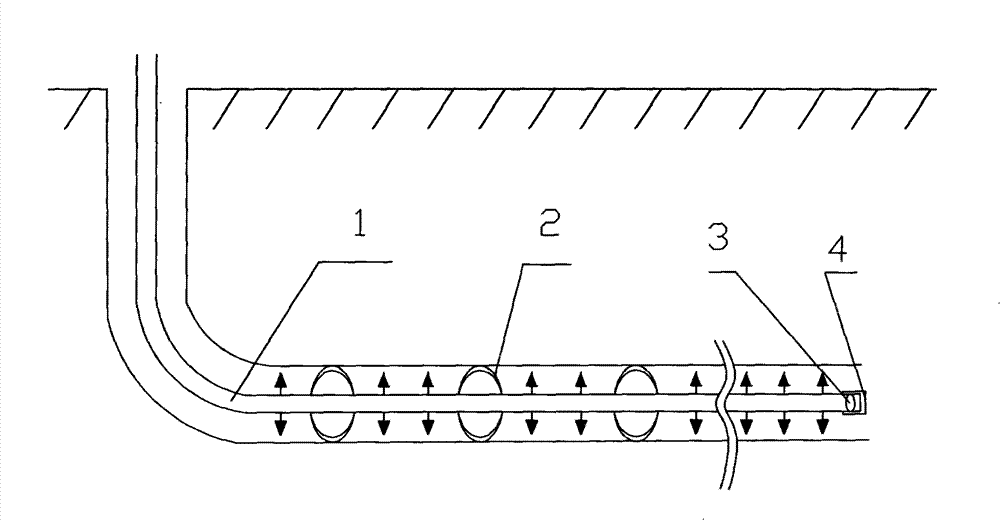

[0037] Such as image 3 As shown, the present invention is a controllable liquid injection pipe that is convenient for going into the well and lifting up, including the controllable liquid injection pipe 1. For the controllable liquid injection, the controllable liquid injection pipe of the present invention is provided with a throttle hole, so The diameter of the throttle hole is 0.2mm~5mm, because the diameter of the throttle hole is too small, image 3 The orifice is not drawn in, ( figure 2 The orifice 5) is marked in the middle, image 3 The direction of the middle black arrow is the injection direction through the orifice. In order to cut off the channeling of the injection medium in the annular space between the liquid injection pipe and the well wall and ensure the controllable liquid injection, the controllable liquid injection pipe of the present invention is provided with a bladder packer 2, such a...

Embodiment 2

[0039] Embodiment 2 Controllable Liquid Injection Pipe Structure

[0040] Such as image 3 As shown, the present invention is a controllable liquid injection pipe that is convenient for going into the well and lifting up, including the controllable liquid injection pipe 1. For the controllable liquid injection, the controllable liquid injection pipe of the present invention is provided with a throttle hole, so The diameter of the throttle hole is 0.2mm~5mm, because the diameter of the throttle hole is too small, image 3 The orifice is not drawn in, ( figure 2 The orifice 5) is marked in the middle, image 3 The direction of the middle black arrow is the injection direction through the orifice. In order to cut off the channeling of the injection medium in the annular space between the liquid injection pipe and the well wall and ensure the controllable liquid injection, the controllable liquid injection pipe of the present invention is provided with a bladder packer 2, such...

Embodiment 3

[0042] Embodiment 3 Controllable Liquid Injection Pipe Structure

[0043] Such as image 3 As shown, the present invention is a controllable liquid injection pipe that is convenient for going into the well and lifting up, including the controllable liquid injection pipe 1. For the controllable liquid injection, the controllable liquid injection pipe of the present invention is provided with a throttle hole, so The diameter of the throttle hole is 0.2mm~5mm, because the diameter of the throttle hole is too small, image 3 The orifice is not drawn in, ( figure 2 The orifice 5) is marked in the middle, image 3 The direction of the middle black arrow is the injection direction through the orifice. In order to cut off the channeling of the injection medium in the annular space between the liquid injection pipe and the well wall and ensure the controllable liquid injection, the controllable liquid injection pipe of the present invention is provided with a bladder packer 2, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com