Scale inhibitor for reverse osmosis membrane and preparation thereof

A technology of reverse osmosis membrane and scale inhibitor, applied in chemical instruments and methods, descaling and water softening, water/sludge/sewage treatment, etc. Efficiency has not yet reached the scale inhibition efficiency and other issues, to achieve the effect of a wide range of applications, improved scale inhibition performance, and reduced cleaning frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Antiscalant formula:

[0023] Hydroxyethylidene Diphosphonic Acid (HEDP) 3%

[0024] 2-Phosphono-1,2,4-tricarboxylic butane (PBTCA) 7%

[0025] Acrylic acid / methyl acrylate copolymer 20%

[0026] Polymaleic acid 1%

[0027] Water 69%

[0028] Static evaluation of reverse osmosis antiscalant test water quality:

[0029] Ca2 + 100mg / L HCO 3 - 100mg / L pH value 8.6

[0030] Scale inhibition test temperature: 80℃±1℃

[0031] Standing time: 10 hours

[0032] Drug dosage: 5mg / L

example 2

[0035] Antiscalant formula:

[0036] Amino Trimethylene Phosphonic Acid (ATMP) 2.5%

[0037] 2-Phosphono-1,2,4-tricarboxylic butane (PBTCA) 6.5%

[0038] Acrylic acid / hydroxypropyl acrylate copolymer 21%

[0039] Polymaleic acid 1%

[0040] Water 69%

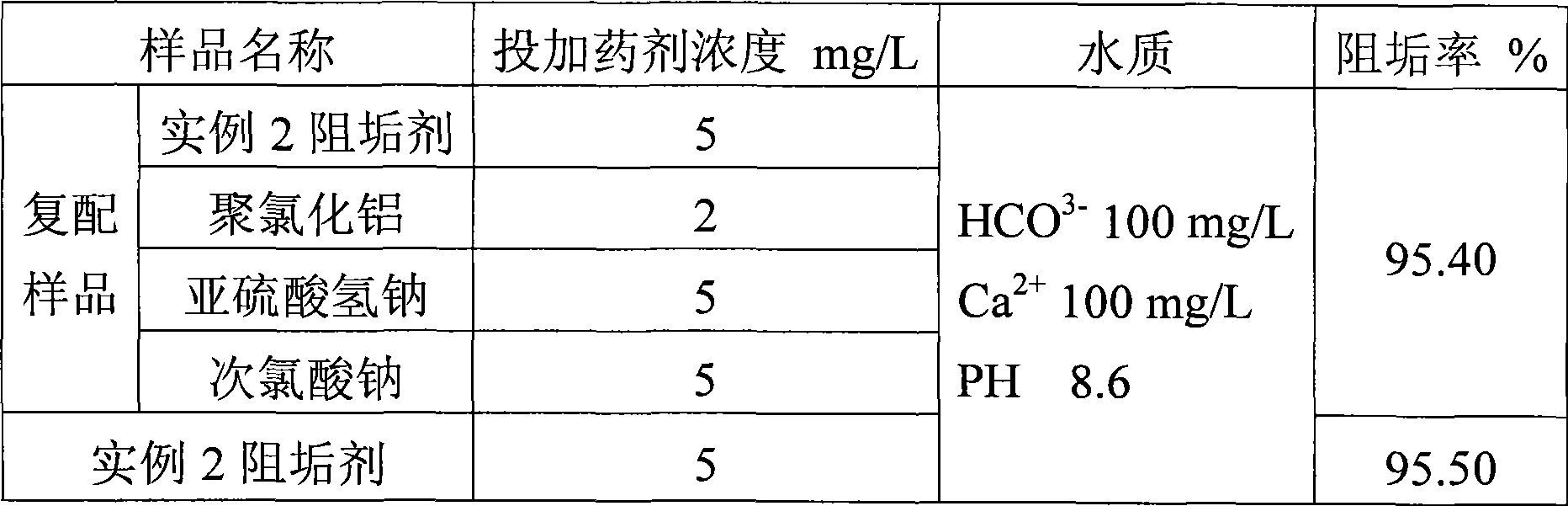

[0041] The antiscalant of the present invention forms a clear solution after being compounded with flocculants, reducing agents, bactericides, etc. added by the reverse osmosis system, and does not become turbid for a long time. The antiscalant was subjected to the static compound antiscaling test, and compared with the antiscaling test of this antiscalant when used in a single agent, the results are shown in the following table:

[0042]

[0043] The data in the table shows that the scale inhibitors in Example 2 have basically similar scale inhibition rates in the presence of flocculants, reducing agents and bactericides, and the scale inhibitors of the present invention have sufficient compatibility and high anti-interf...

example 3

[0045] Antiscalant formula is the same as Example 1

[0046] It is operated on a reverse osmosis equipment with a water treatment capacity of 100 tons / hour in a certain company, and the dosing concentration is 5mg / L.

[0047] Influent water quality:

[0048] Na + 395mg / L HCO 3 - 340mg / L

[0049] Ca 2+ 7.00mg / L Cl - 80.0mg / L

[0050] Mg 2+ 13.5mg / L SO 4 2- 86.50mg / L

[0051] Fe 3+ 0.30mg / L CO 3 2+ 20mg / L

[0052] AL 3+ 0.15mg / L SDI <3

[0053] SiO 2 2- 20.0mg / LCOD Mn 1.5mg / L

[0054] Total Hardness 25mg / L PH 8.70

[0055] After 10 months of operation, the pressure difference in the second stage of the reverse osmosis membrane dropped from 0.14 MPa to 0.09 MPa, the desalination rate remained above 98.5%, and the purified water output decreased by 8.5%. The cleaning cycle was extended from 2.5 to 3 months to 10 moon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com