Ventilated anti-blocking composite filter tube structure and method for banding the same

A filter tube and anti-silting technology, applied in separation methods, infrastructure engineering, chemical instruments and methods, etc., can solve problems such as filter layer silting, and achieve the effects of low cost, convenient use, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

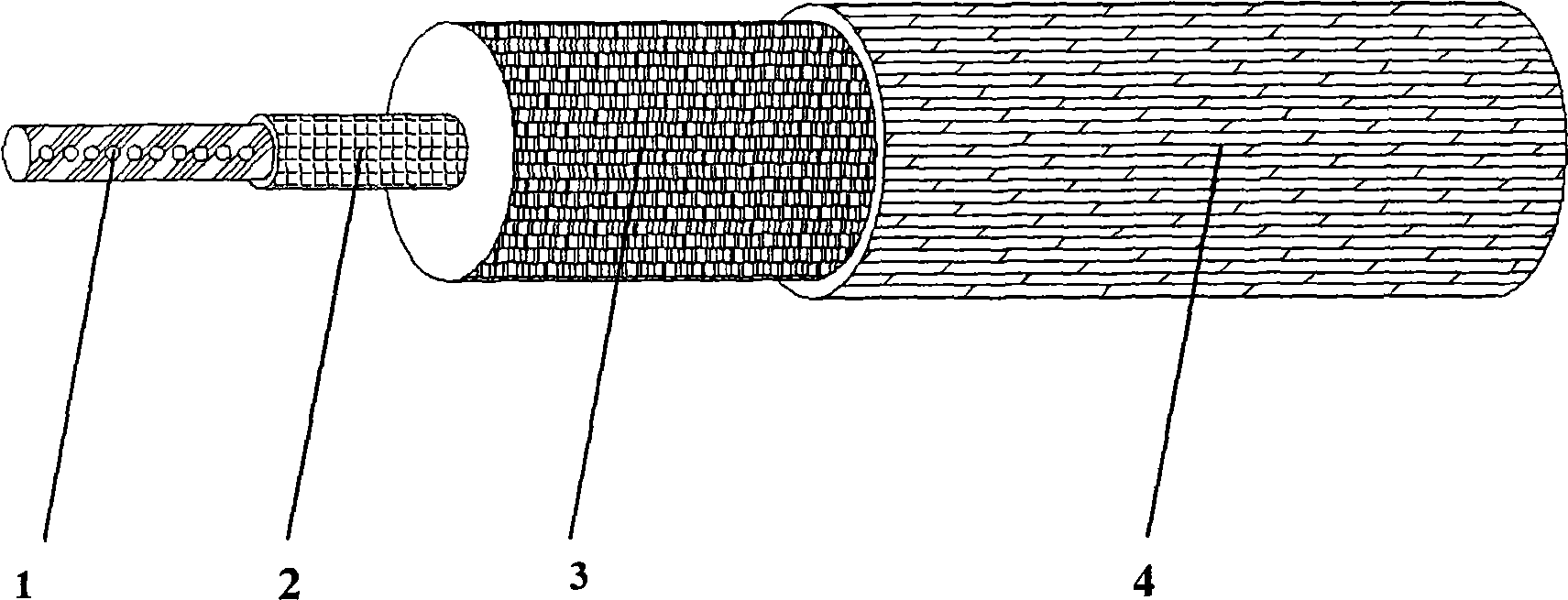

[0014] control attached figure 1 , its structure is a four-layer structure, from inside to outside as follows: low-conductance inner tube 1, water filter layer 2, air-permeable porous filling material 3, and high-permeability water-permeable outsourcing material 4.

[0015] As for the low flow conductance inner tube 1 , flow conductance is a concept in fluid mechanics, which is the amount of air flowing through the conduit under a unit pressure difference. The relationship of conductance to piping systems can be compared to the relationship of electrical resistance to electrical circuits. The low-conductance inner pipe is made of densely drilled hard plastic pipes (such as PVC, PP, PE pipes). For deep silt yards, galvanized iron pipes with densely drilled holes should be used for deep-buried piping systems. As a low-conductance inner tube, it increases its pressure resistance. The diameter of the low conductance inner tube 1 is generally between 3cm and 10cm.

[0016] The m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Filling thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com