Technique for producing run-resistant spandex core-spun silk stockings

A spandex core-spun, production process technology, applied to socks, pantyhose, yarn, etc., can solve the problems of scarcity of raw materials, immature technology, difficulty in popularization, etc., and achieve the goal of reducing production costs, facilitating large-scale production and wide use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

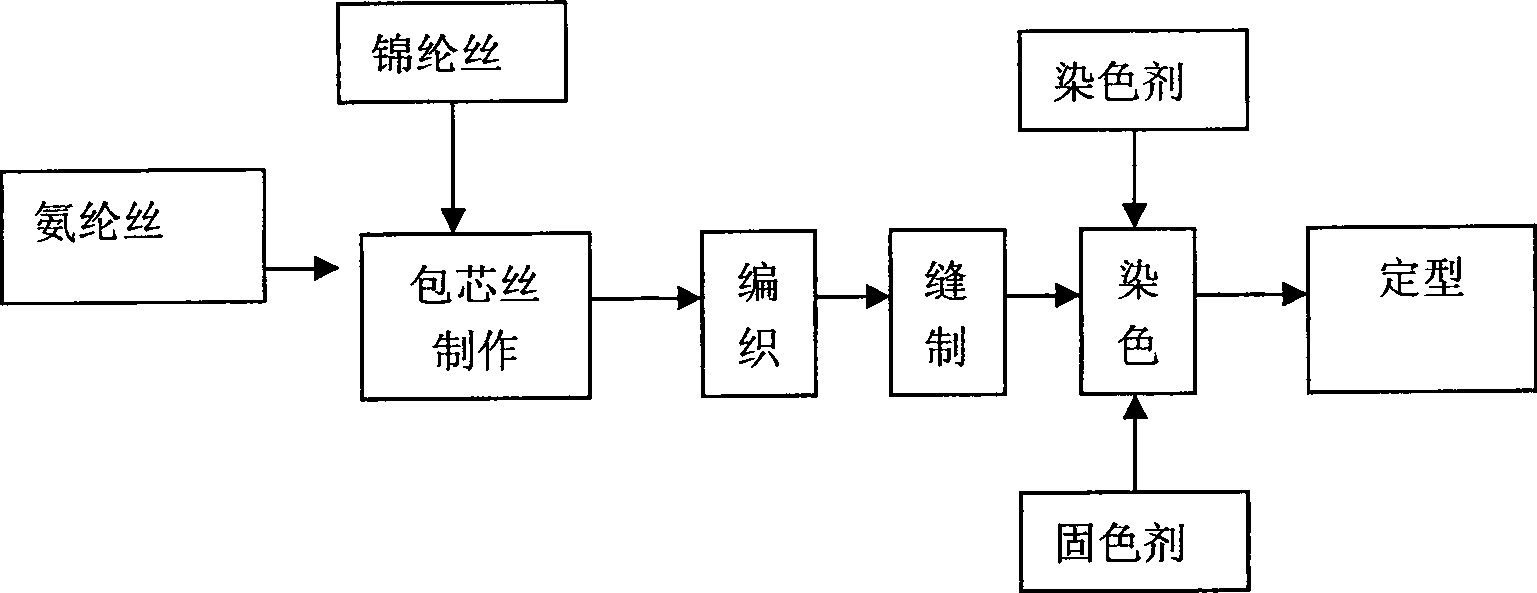

[0023] figure 1 Described, the technology realized by the present invention comprises the following steps:

[0024] A. Production of cored wire:

[0025] Spandex is first stretched according to a certain draft ratio, then nylon is used as the outer wrapping yarn, and it is wrapped on a high-speed wrapping machine to make a core-spun yarn (CR) suitable for weaving;

[0026] The spandex is 20D type spandex, the outsourcing yarn is nylon DT12 / 7 type (DT20 / 5 or other types can also be selected according to needs), the motor speed is 20000 rpm, the draft ratio is 3, the twist is 1300T / M, and the overfeed is 94 %, the working temperature is 25°.

[0027] B. Weaving:

[0028] After the core-spun silk (CR) is balanced for a certain period of time (5 days, the temperature is controlled at 25°), the core-spun silk is fed into the knitting machine for weaving to make semi-finished stockings;

[0029] On each thread path of the knitting machine, use KTF (automatic yarn feeder), throug...

Embodiment approach 2

[0040] A. Production of cored wire:

[0041] The special spandex is first stretched according to a certain draft ratio, and nylon is used as the outer wrapping yarn, which is wrapped on a high-speed wrapping machine to make a core-spun yarn suitable for weaving;

[0042] Choose 15D model for spandex, DT12 / 7 model for nylon (or DT20 / 5 or other models according to needs), the motor speed is 25000 rpm, the draft ratio is 2, the twist is 1800T / M, and the overfeed is 95%. The temperature is 20°.

[0043] B. Weaving:

[0044] After the core-spun silk is balanced for a certain period of time (7 days, the temperature is controlled at 20°), the core-spun silk is sent into the knitting machine for weaving to make semi-finished stockings;

[0045] On each thread path of the knitting machine, use KTF (automatic yarn feeder), through the buffering and balancing effect of KTF, the tension of each thread is controlled to 0.15-1G, thus solving the problem of poor texture; by adjusting The ...

Embodiment approach 3

[0055] A. Production of cored wire:

[0056] Spandex is first stretched according to a certain draft ratio, and nylon is used as the outer wrapping yarn, which is wrapped on a high-speed CV machine to make a core-spun yarn suitable for weaving;

[0057] Spandex uses 70D type spandex yarn, nylon uses DT12 / 7 type (DT20 / 5 or other types can also be selected according to needs), the motor speed is 22000 rpm, the draft ratio is 2.5, the twist is 1600T / M, and the overfeed is 94.5%. , the working temperature is 22°.

[0058] B. Weaving:

[0059] After the core-spun silk is balanced for a certain period of time (8 days, the temperature is controlled at 22°), the core-spun silk is sent to the weaving workshop for weaving to make semi-finished stockings;

[0060] On each thread path of the knitting machine, use KTF (automatic yarn feeder), through the buffering and balancing effect of KTF, the tension of each thread is controlled to 0.15-1G, thus solving the problem of poor texture; b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com