Lamp strip body, lamp strip and method for manufacturing the lamp strip

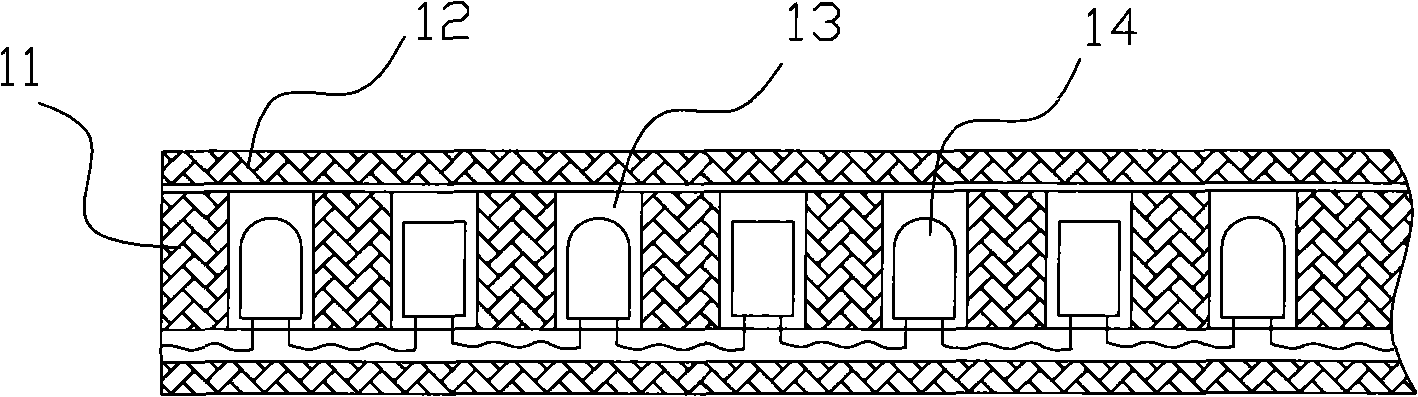

A manufacturing method and technology for light strips, which are applied in the field of lighting, can solve the problems such as failure to replace the extinguished light string, failure to check the failure of the light source 14, etc., and achieve the effects of convenient replacement, good decorative effect, and prolonged service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

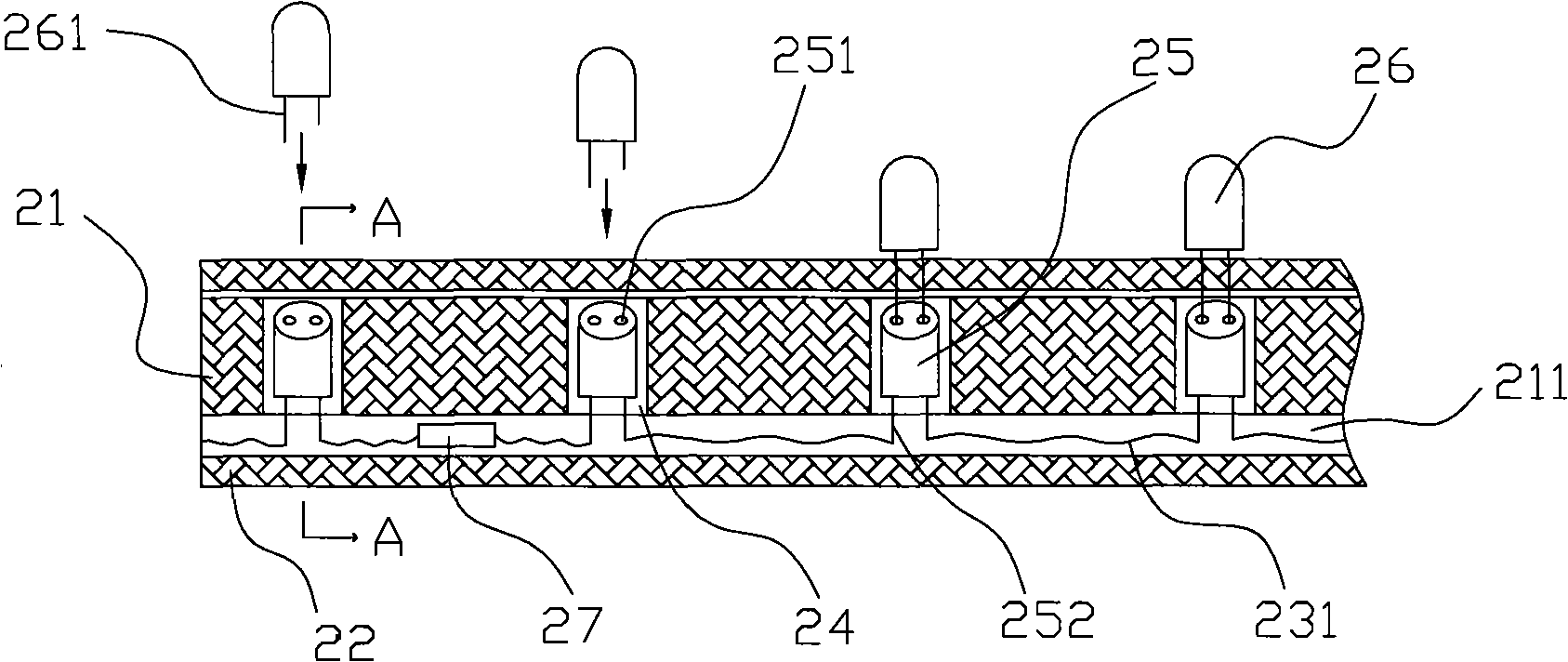

[0020] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings.

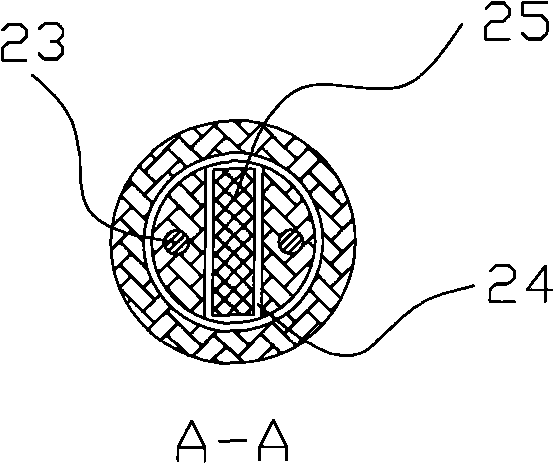

[0021] see Figure 2a , is a cross-sectional view of the light strip according to the first embodiment of the present invention. The light strip includes a light strip body and a light source 26 . The light strip body includes a core wire and a cladding layer 22 covered outside the core wire, and a main power line 23 (such as Figure 2b As shown), the core wire 21 is provided with a plurality of transverse holes 24, and the transverse holes 24 are equipped with a terminal block 25 for inserting the light source lamp pin 261, and the terminal block 25 is electrically connected with the main power line 23.

[0022] Because the terminal block 25 is installed in the transverse hole 24, the light source 26 is inserted into the terminal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com