Convection tide-discharge heat conducting wood floor block and wood floor spliced thereby

A technology for solid wood floors and floor boards, which is applied in heating methods, household heating, heating systems, etc., can solve the problems of polluting the environment, inability to keep paint flat, and difficult to promote and popularize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

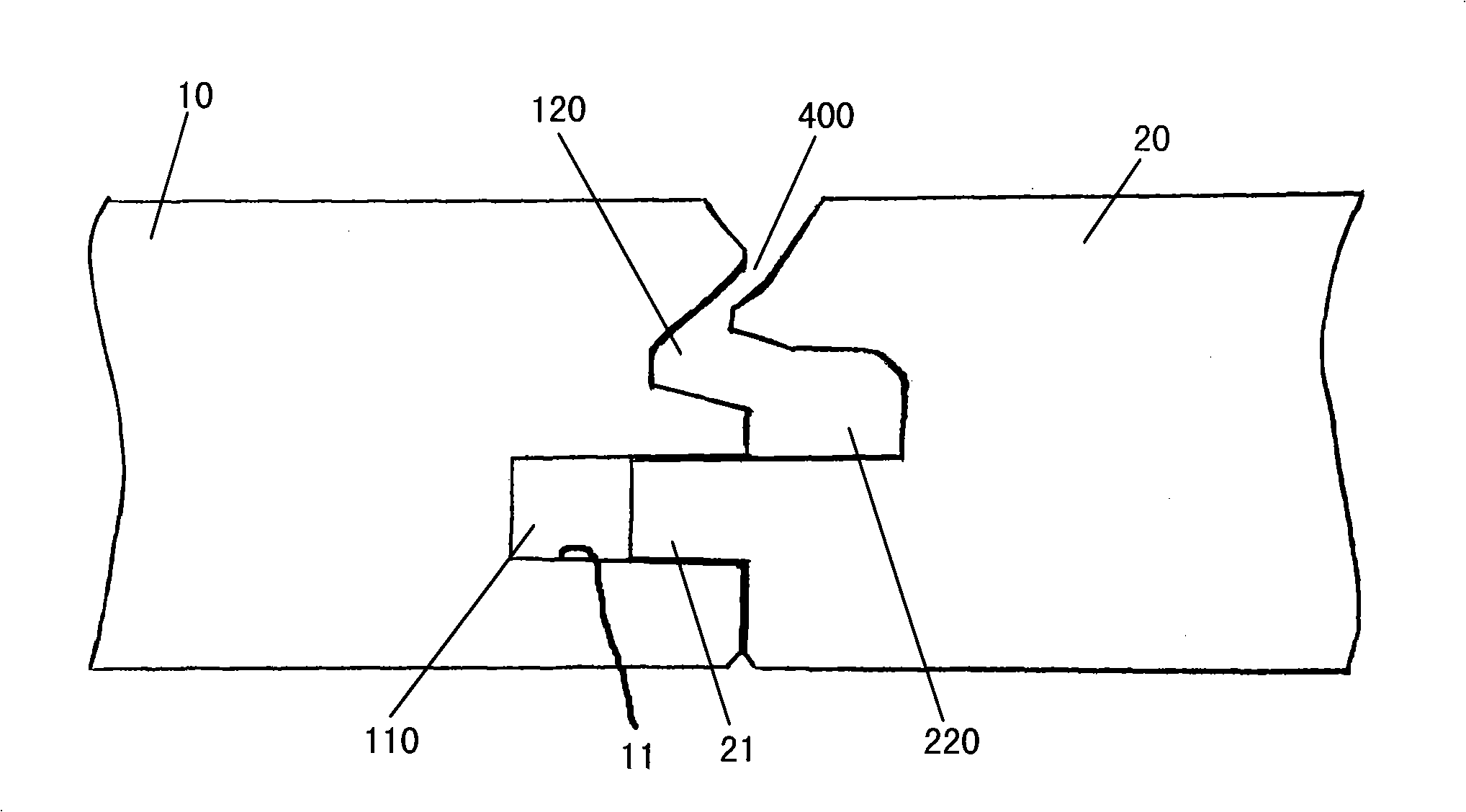

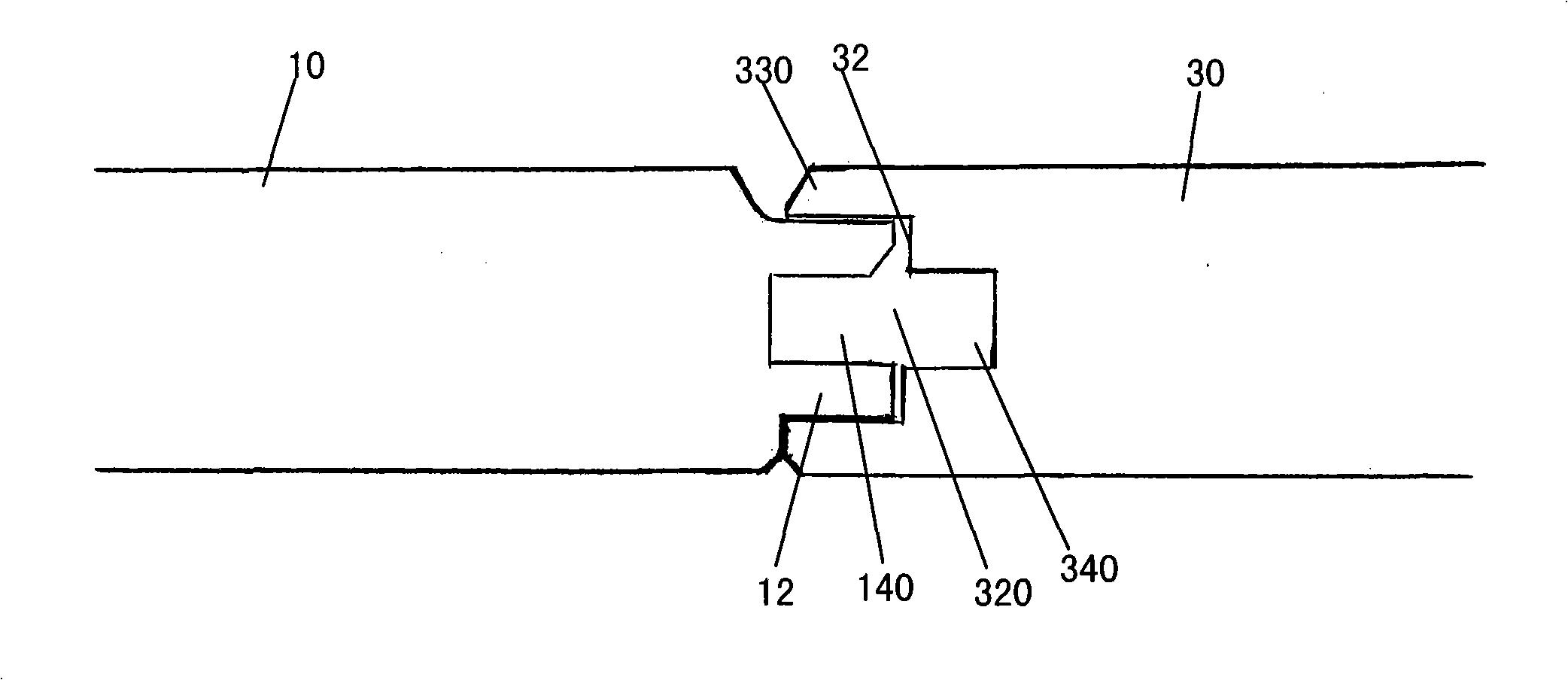

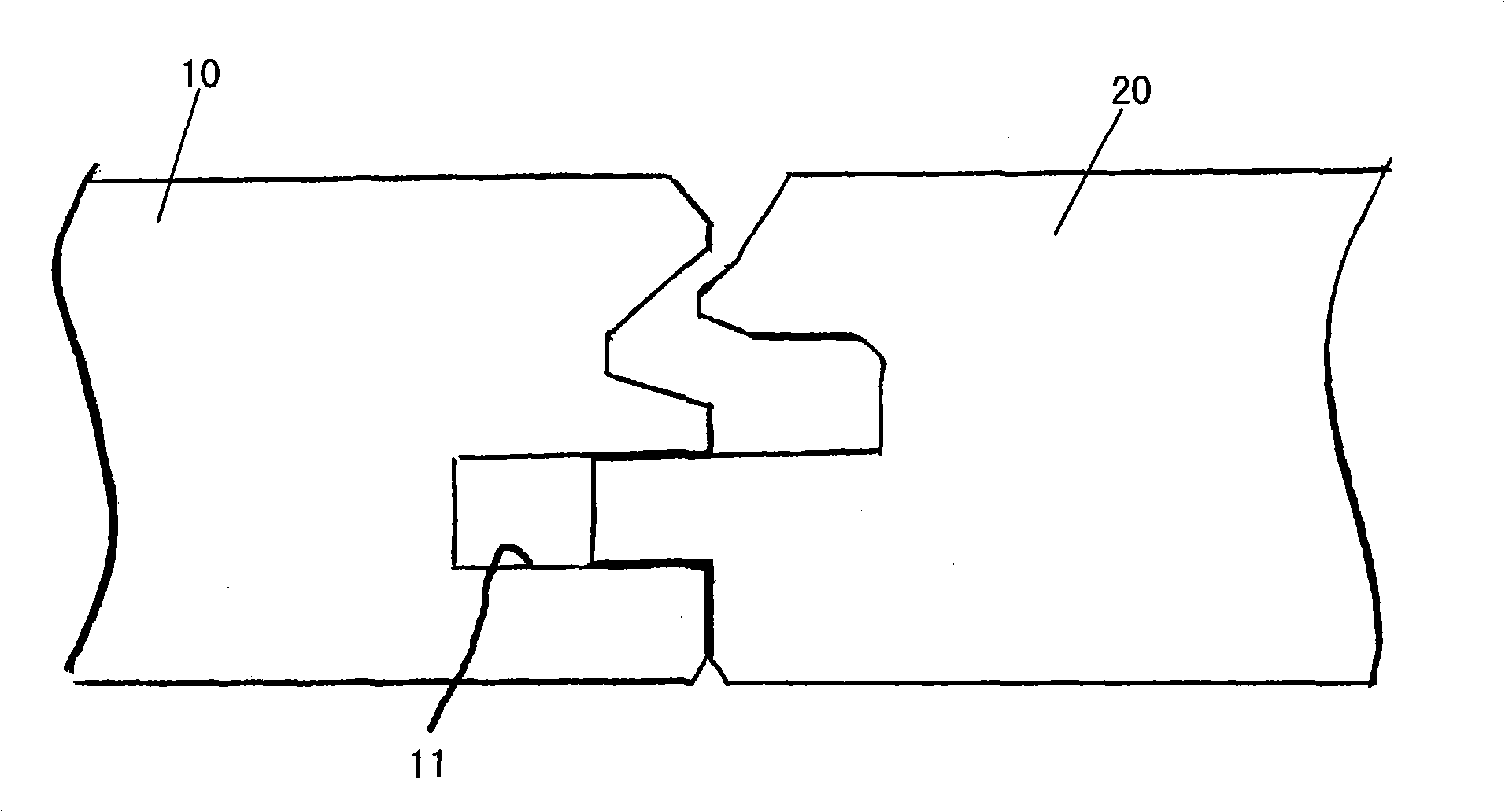

[0036]In the following description, for simplicity, "floor board" and "floor" mean "solid wood floor board" and "solid wood floor". The longitudinal direction of the floor board is the direction consistent with the grain direction of the floor (usually the In the length direction, the expansion and contraction of the floorboard along this direction is very small), while the transverse direction of the floorboard refers to the direction perpendicular to the grain direction of the floor (usually the width direction of the floorboard, the expansion and contraction of the floorboard along this direction is the largest ), in addition, "solid wood floor board" should be understood in the broadest sense, for example, it can be understood as a floor board containing solid wood with tidal shrinkage properties, which can be composed of one or more layers of solid wood; "horizontal convection trough" It refers to the convection groove formed at the bottom of the "transverse groove" and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com