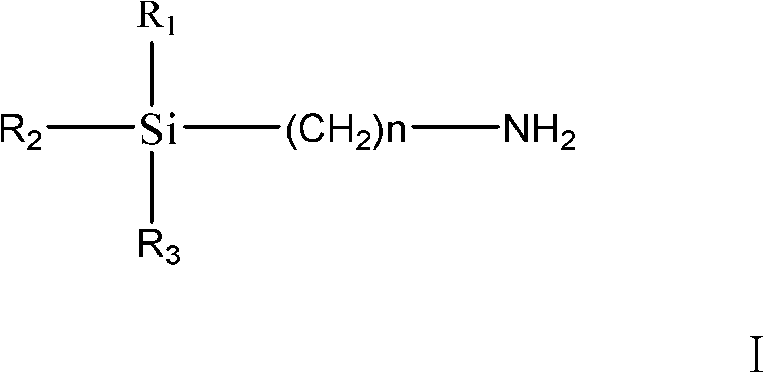

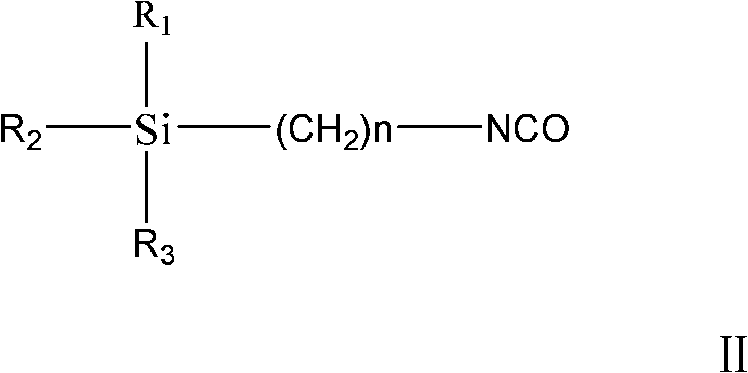

Method of preparing trialkoxysilanes isocyanic ester

A technology of trialkoxysilyl isocyanate and trialkoxysilyl propyl isocyanate, which is applied in the field of preparation of trialkoxysilyl isocyanate, can solve the problems of unsafe and reliable, weak operability, etc., and avoid Effect of phosgene, low price, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present embodiment is the preparation method of triethoxysilyl propyl isocyanate, specifically comprises the following steps:

[0022] ① Put a 2L reaction device with a stirrer and a thermometer into an ice-salt bath, and control the temperature 3 Dissolve in 600ml of water, then add to the reaction device and stir, and control the temperature at 5°C to 0°C.

[0023] ②Dissolve 25.4g of triphosgene in 400ml of CH 2 Cl 2 in, and then added to the reaction device; 45.12 g of triethoxysilylpropylamine was dissolved in 400 ml of CH 2 Cl 2 Then add it to the reaction device, stir and react for 15 minutes, and control the temperature at -5°C to 10°C.

[0024] ③ Place the reacted solution to separate the phases into aqueous phase and organic phase, and use 100ml of CH for the aqueous phase 2 Cl 2 Extract twice, combine the organic phase obtained after extraction and the organic phase obtained during phase separation, then dry, filter with suction, and remove CH 2 Cl ...

Embodiment 2~ Embodiment 5

[0027] The preparation method of each embodiment is basically the same as that of Example 1, and the specific parameters of each embodiment are shown in Table 1, wherein the finished product obtained in Example 4 is trimethoxysilylpropyl isocyanate, and all the other are triethoxysilylpropyl isocyanate .

[0028] Example 1

Example 2

Example 3

Example 4

Example 5

Reactor volume

2L

5L

20L

2L

500L

60g

NaHCO 3

160g

NaHCO 3

700g

NaHCO 3

43.1g

NaHCO 3

14kg

NaHCO 3

Water in which chlorine scavenger is dissolved

600ml

2L

7L

600ml

140L

25.4g

60g

250g

25.4g

5kg

dissolved triphosgene

CH 2 Cl 2

400ml

1000ml

3L

400ml

60L

Trialkoxysilylamine

45.12g

Triethoxy

silyl propyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com