Method for producing water absorbent resin particle

A resin particle, water-absorbing technology, applied in the field of producing water-absorbing resin, can solve problems such as cost increase, property degradation, and insufficient particle size control, and achieve high productivity, enhanced basic properties, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

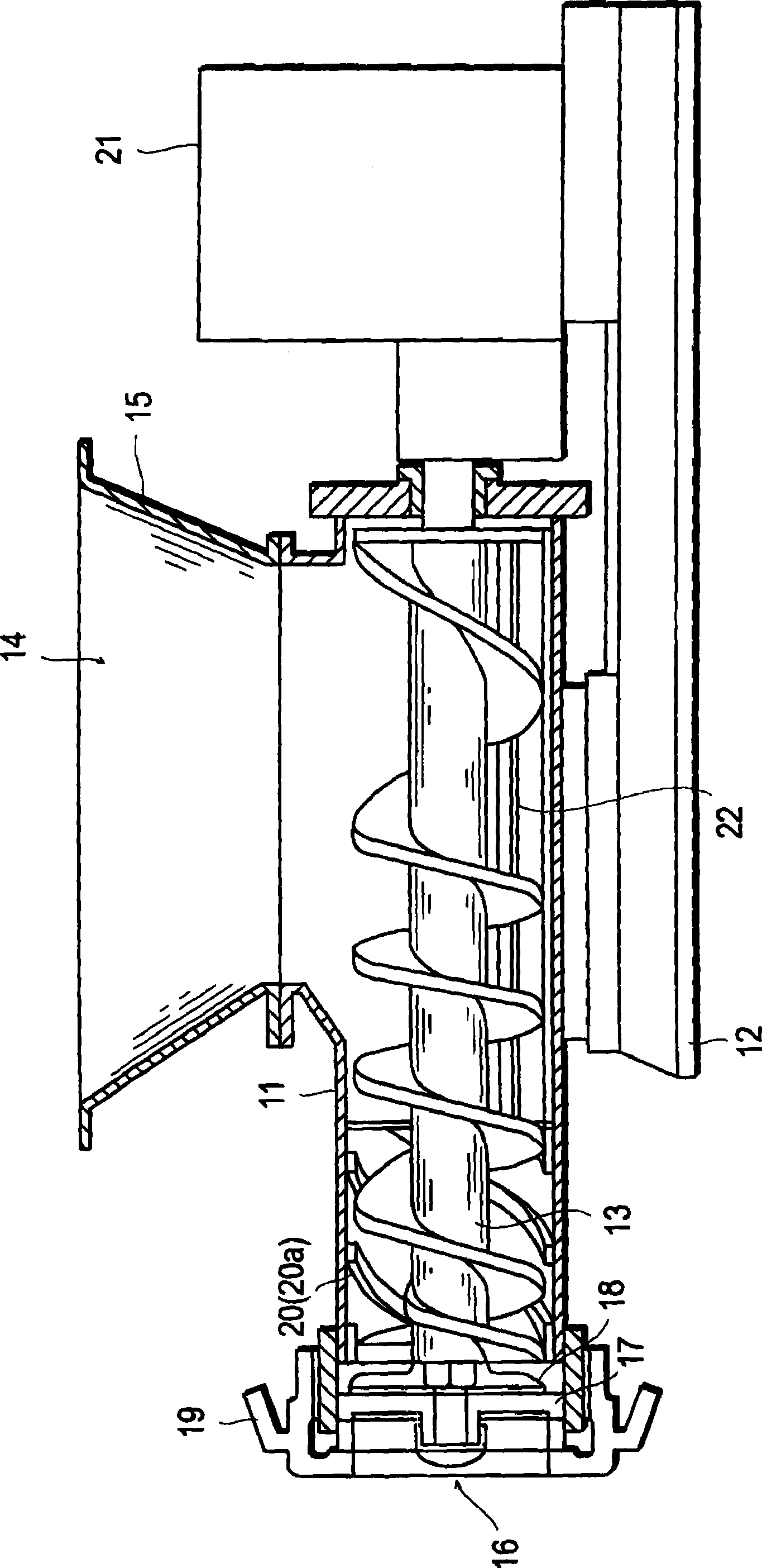

[0041] Coexistence here means that the hydrogel (a) and the hydrogel (b) are present together in the fine granulation device, and suitably, the hydrogel (a) and the hydrogel (b) are together during the fine granulation step The state that exists in a fine-grained device. For example, the following embodiments are included: the hydrogel (a) and the hydrogel (b) are simultaneously started to be loaded into the fine granulation equipment, and the loading is completed at the same time; (a) and hydrogel (b) are mixed, and then loaded into a fine granulation device. The mixing of hydrogel (a) and hydrogel (b) can be carried out continuously, semi-continuously or in batch mode.

[0042] Explanations regarding materials and equipment used in the fine granulation step will be given below in detail.

[0043] (Water-swellable, hydrogel-like crosslinked polymer (a))

[0044] In the present invention, the water-swellable, hydrogel-like crosslinked polymer (a) obtained through the crossl...

Embodiment

[0155] Based on Examples, the present invention will be described more specifically below, however, the present invention should not be limited to these Examples. It should be noted that hereinafter, for convenience, "parts by weight" may be abbreviated as "parts", "liter" may be abbreviated as "L", and "milliliter" may be abbreviated as "mL". In addition, "weight%" may be described as "wt.%". In addition, the water-absorbent resin is used (treated) under conditions of 25°C±2°C and a relative humidity of about 50%±5% RH. In addition, as a normal saline solution, a 0.90% by weight sodium chloride aqueous solution was used.

[0156] It should be noted that in the case of analyzing a commercially available product such as a water-absorbent resin in a disposable diaper and when it is in a hygroscopic state, it can be measured after adjusting the water content to about 5% by drying under an appropriate reduced pressure .

[0157] (centrifuge retention capacity (CRC))

[0158] I...

reference example 1

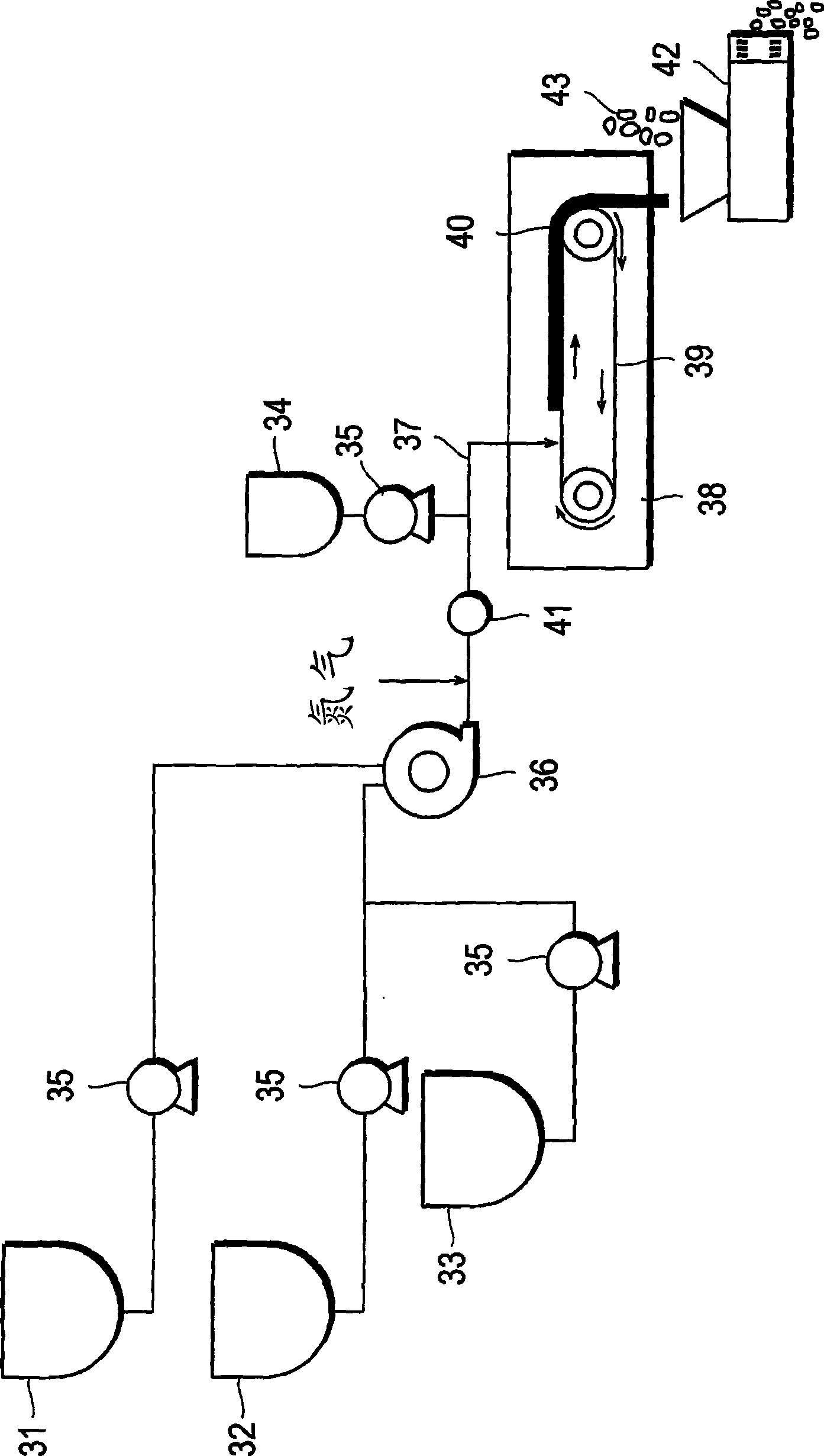

[0189] Prepare (A) 48.5wt.% sodium hydroxide aqueous solution, (B) 54.3wt.% acrylic acid aqueous solution, (C) polyethylene glycol diacrylate (average molecular weight 523) by 9.33wt.% respectively, 0.30 wt.% of hydroxycyclohexyl benzophenone, 0.37wt.% of 46wt.% trisodium diethylene triamine pentaacetate aqueous solution, 45.0wt.% of acrylic acid and 45.0wt.% of industrial pure water Solution, and the aqueous solution of (D) 3.0wt.% sodium persulfate, and each solution is packed in the groove 31 of storage aqueous solution (A), in the groove 32 of storage aqueous solution (B), the groove of storage solution (C) 33, and in the tank 34 for storing the aqueous solution (D) (see figure 2 ). The solution temperature in each tank was set as follows: 33°C for the aqueous solution (A), 11°C for the aqueous solution (B), 24°C for the aqueous solution (C), and 24°C for the solution (D). It should be noted that installing the pump 35 in figure 2 in each slot.

[0190] by using the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com