Wafer retaining system and semiconductor processing apparatus applying the system

A semiconductor and chip technology, applied in the field of microelectronics, can solve problems such as difficult control, reduced service life of components, increased cost, etc., and achieve the effects of increasing heat transfer effect, improving product yield, and improving temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solution of the present invention, the wafer clamping system provided by the present invention and the semiconductor processing equipment using the clamping system will be described in detail below with reference to the accompanying drawings.

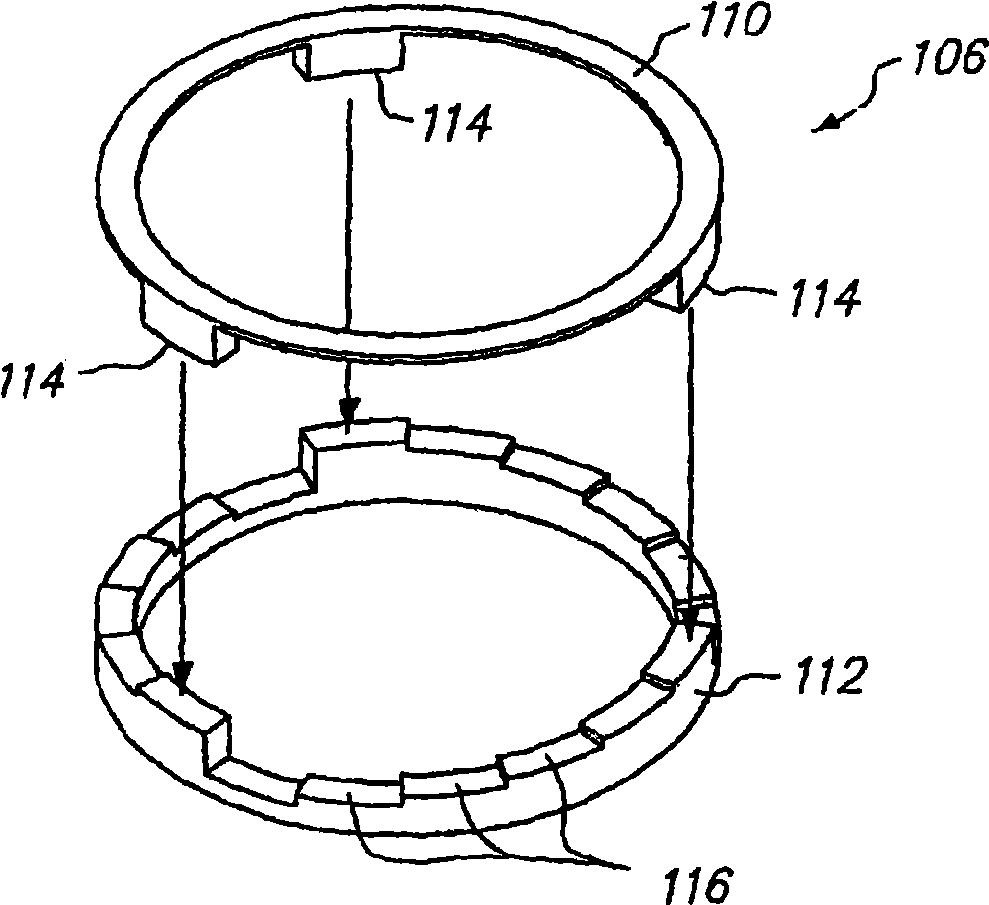

[0044] The wafer clamping system provided by the present invention may include: a clamping tool such as an electrostatic chuck; a movable base ring disposed around the clamping tool; a focus ring placed on the movable base ring, and is also arranged around the clamping tool; and a lifting adjustment assembly, which includes a first adjustment part and a second adjustment part, and the first adjustment part and the second adjustment part cooperate with each other so that the movable base ring is relatively The clamping tool can be continuously lifted to drive the focus ring on the movable base ring to continuously lift, so that the distance between the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com