Manufacturing process for deep sea water tight electric cable

A production method, technology of watertight cables, applied in submarine cables, cable/conductor manufacturing, insulating conductors/cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

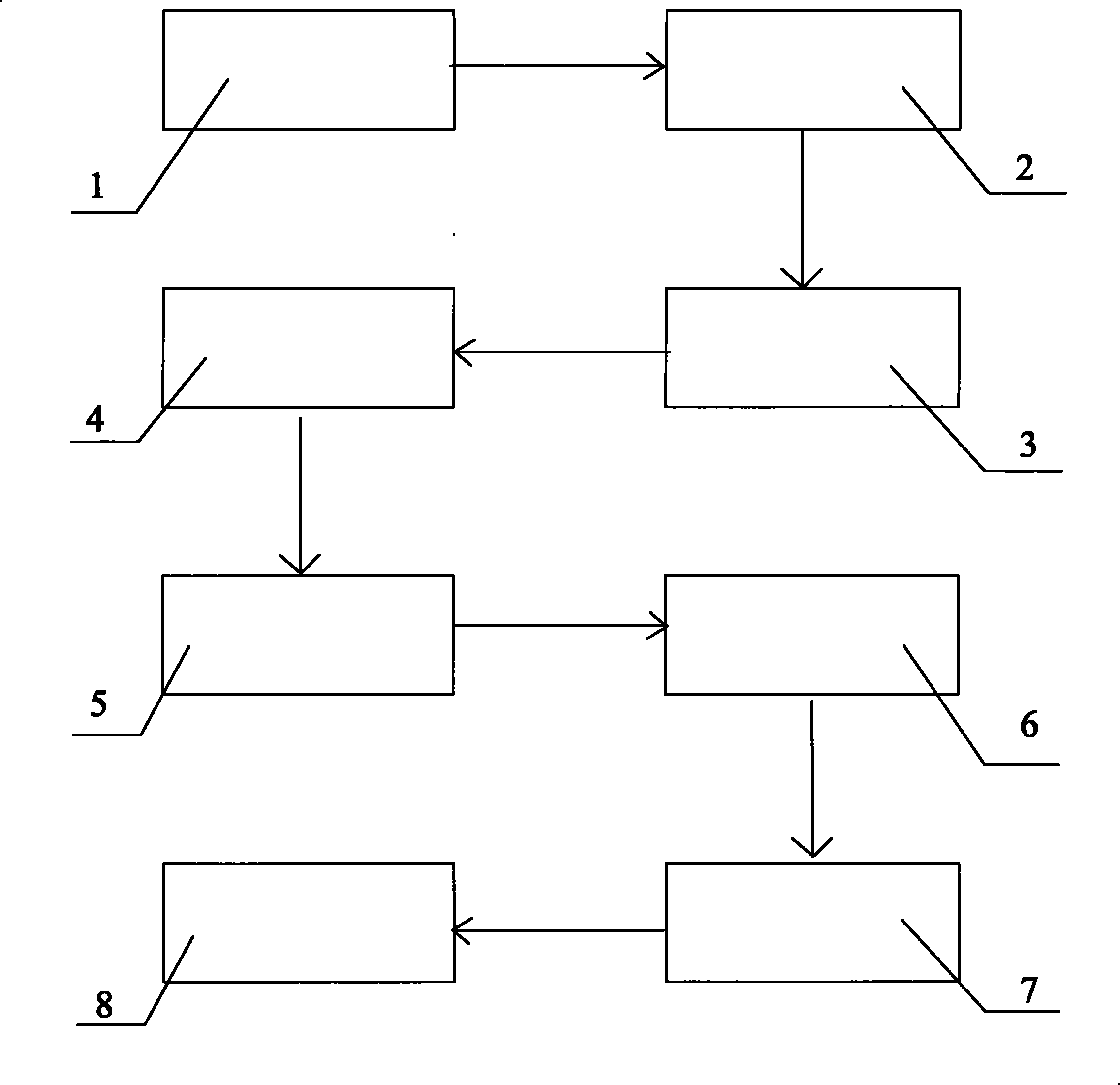

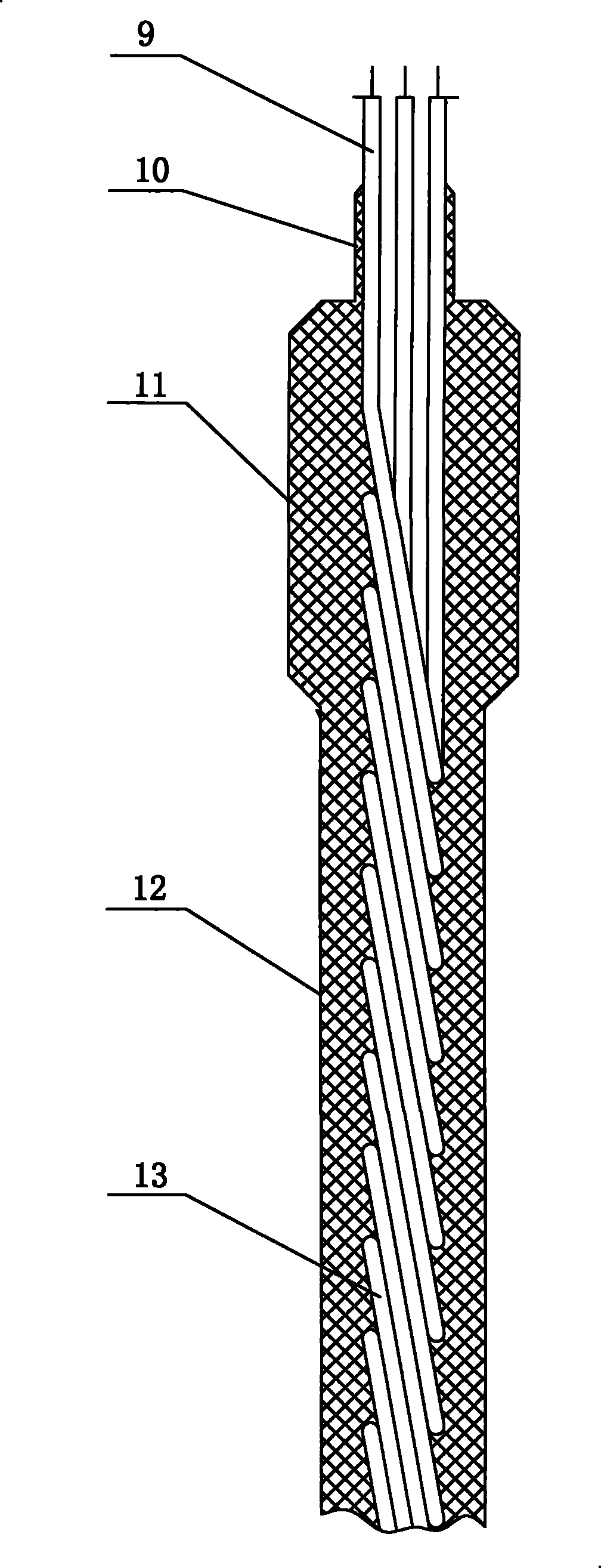

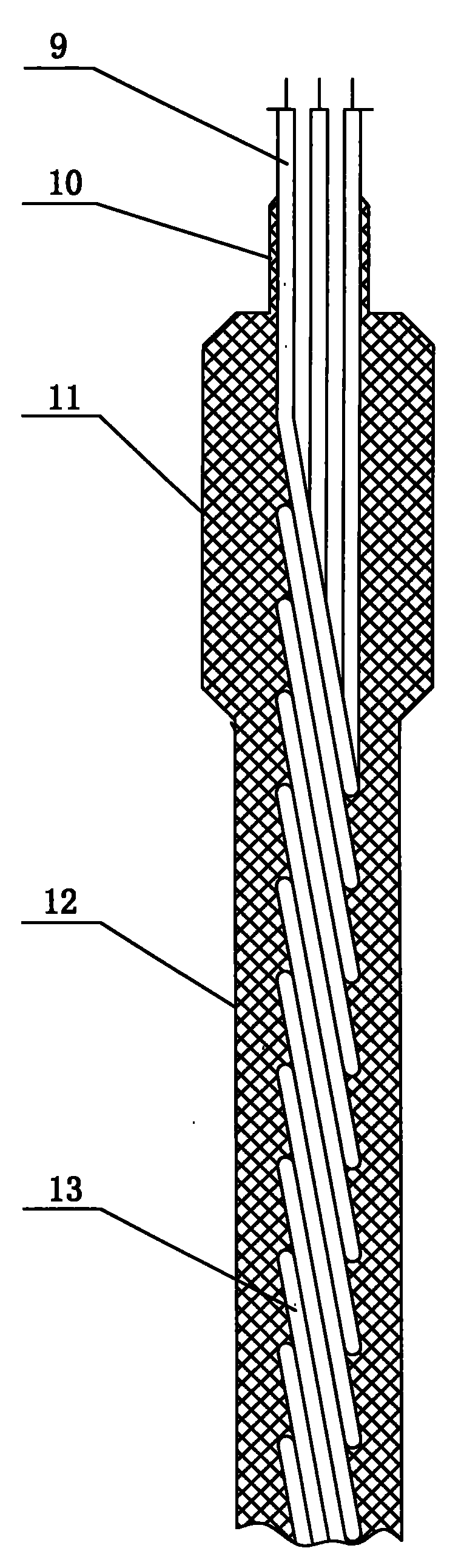

[0020] Embodiments of the present invention are provided below: the present invention includes the making of conductive core wire 9 as a cable, the making of refining film, rubber slices, cable core sheath making, die preheating, coating release agent, core cable mold loading And the eight process steps of machine vulcanization, in the production process of 9 conductive core wires into cables, according to the required number of watertight cable core wires, the conductive core wires are made into cable cores; in the production process steps of refining film, press The difference between the cable diameter D+2mm of the watertight cable and the cable core diameter D determines the thickness H of the refined film, and then the deep-sea special chloroprene rubber is refined into a film; in the rubber slicing step, the refined deep-sea special The neoprene is sliced according to the width dimension of the cable diameter D×2mm of the watertight cable; in the manufacturing step of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com