Three-axial vibration composite testing apparatus

一种复合试验、轴向振动的技术,应用在振动测试、测量装置、机器/结构部件的测试等方向,能够解决影响刚性、增加运动部件质量、运动部质量大等问题,达到提高抗倾覆力矩的能力、减少中间立方体、降低制造的难度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

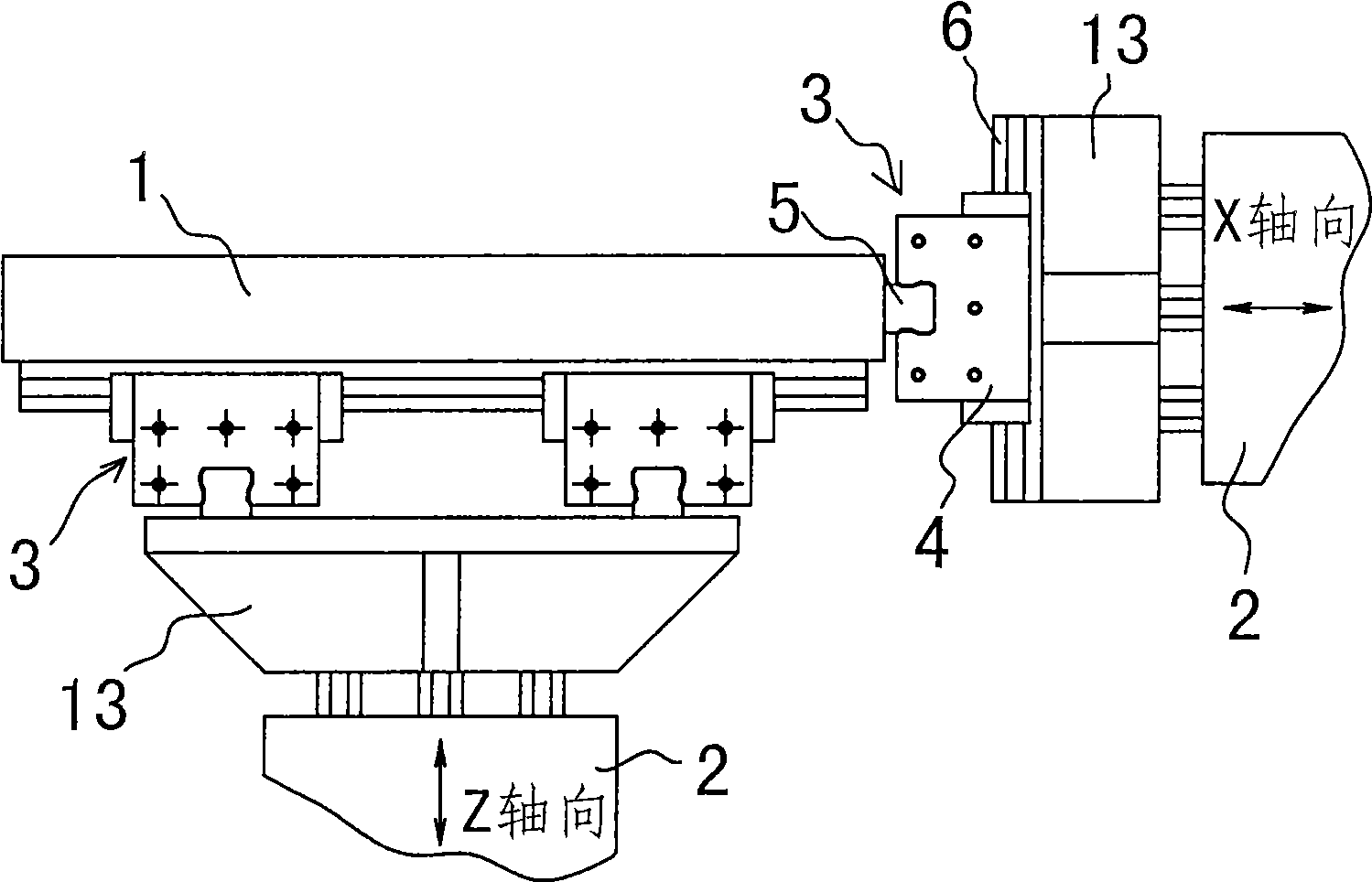

[0041] Embodiment one: see attached Figure 4~5 As shown, a three-axis vibration composite test device has a working table 20, and the working table 20 is connected to the Z-axis vibration generator 21 through the first axial vibration transmission mechanism 24 in the vertical Z-axis, and the horizontal The X-axis is connected to the X-axis vibration generator 22 via the second axial vibration transmission mechanism 25 , and the Y-axis vibration generator 23 is connected to the horizontal Y-axis via the third axial vibration transmission mechanism 26 .

[0042] The first axial vibration transmission mechanism 24 includes upper and lower splints 27, 28 and a central panel 29. A connecting body 41 is arranged under the working surface 20. The cross section of the connecting body 41 is "H-shaped", and the top end of the circumferential wall is It is fixedly connected with the bottom surface of the work surface 20, and its central transverse plate body is the central panel 29, and...

Embodiment 2

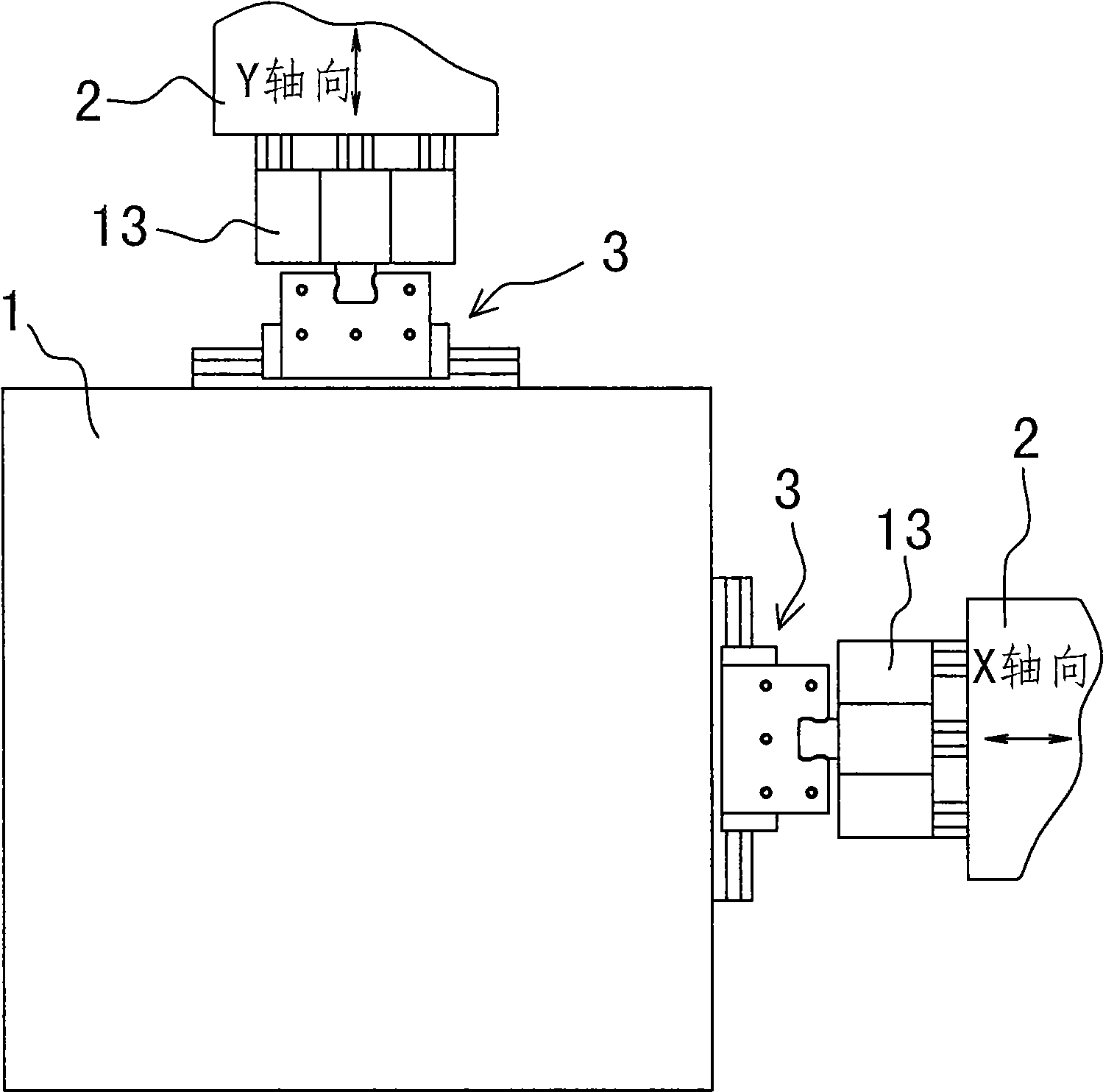

[0047] Embodiment two: see attached Figure 6~7 As shown, a triaxial vibration compound test device has a working table 20, and the difference from Embodiment 1 is that there is no connecting body 41, and the upper surface of the upper splint 27 is directly used as the working table 20, and the center panel 29 The bottom surface is fixedly connected to the connecting piece 37, and is connected with the vibrating body of the Z axial vibration generator 21 through the connecting piece 37; on the lower clamping plate 28, the avoidance connecting piece 37 has an escape groove 43; the side portion of the upper clamping plate 27 is directly connected to the second The axial vibration transmission mechanism 25 is fixedly connected to the transverse guide rail 32 in the third axial vibration transmission mechanism 26 . An annular dust-proof film 39 is connected between the circumference of the bottom of the upper splint 27 and the top of the Z-axis guide bracket 35 to close the circum...

Embodiment 3

[0048] Embodiment three: see attached Figure 8 As shown, a three-axis vibration composite test device includes a working table 20, three vibration generators and three axial vibration transmission mechanisms; the difference from Embodiment 1 is that the second axial vibration transmission mechanism 25 and the third axial vibration transmission mechanism 26 are cross linear guide rail pairs, and each cross linear guide rail pair respectively includes a transverse guide rail 32, two longitudinal guide rails 33 and two sliders 31, and the two longitudinal guide rails 33 are arranged in parallel, and the transverse guide rails 32 and two longitudinal guide rails 33 are distributed in a cross, and a slide block 31 is respectively set at the two intersection points. Of course, the transverse guide rail 32, the longitudinal guide rail 33 and the slide block 31 are still slidingly connected. The longitudinal guide rails 33 in the two parallel second axial vibration transmission mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com