Electronic weighing scale

A weight meter and electronic technology, applied in the direction of weighing, measuring devices, weighing auxiliary equipment, etc., can solve the problem of limited thinning and achieve the effect of thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

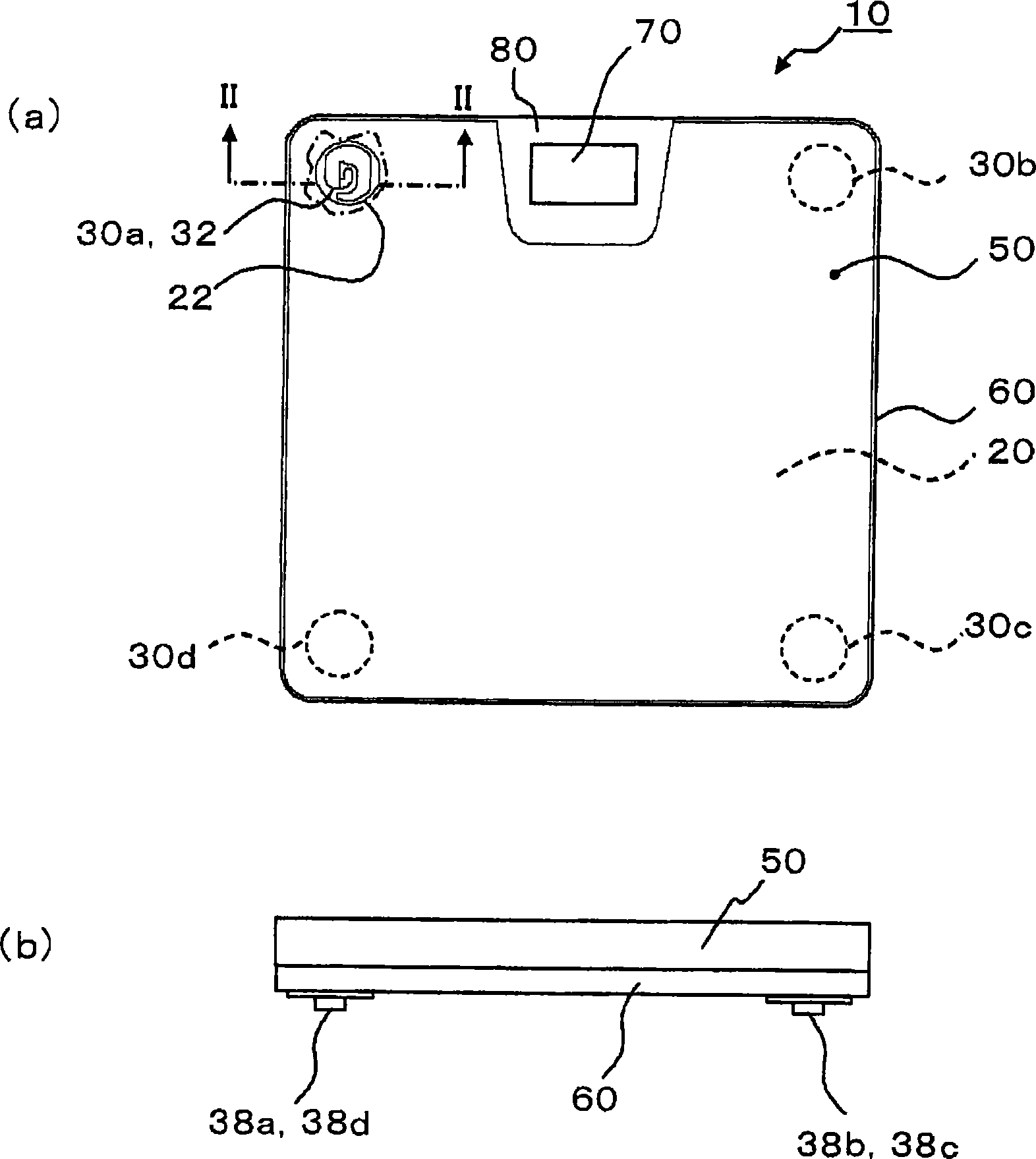

[0030] First, the outline of the electronic weighing scale 10 of this embodiment will be described.

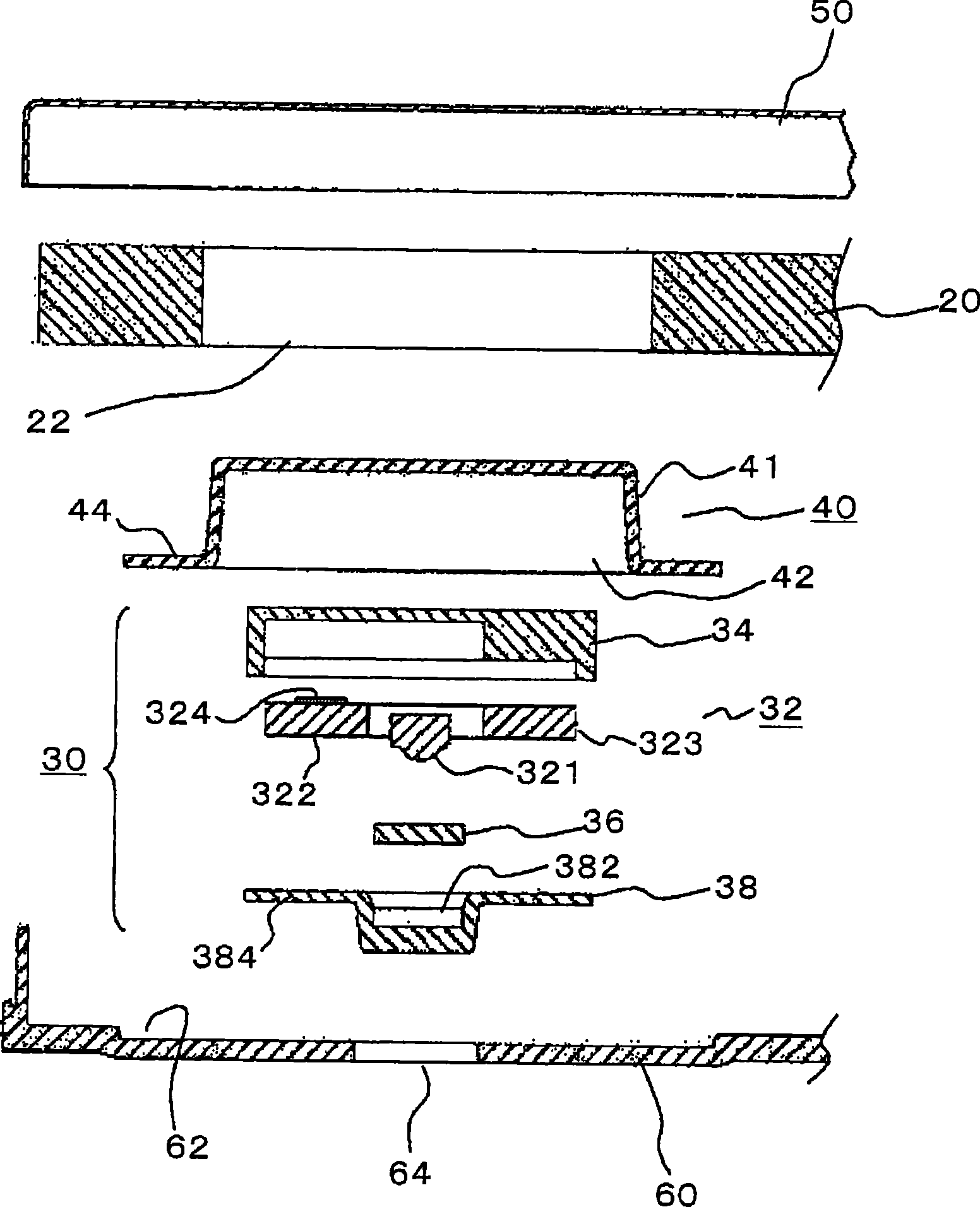

[0031] The electronic weighing scale 10 includes a top plate member 20 on which an object to be measured (not shown) is placed on an upper surface, and a load cell unit 30 supporting the top plate member 20 from below, and at least a part of the load cell unit 30 is buried in the top plate member 20 installed in.

[0032] Next, the electronic weight scale 10 of this embodiment will be described in detail.

[0033] figure 1 (a) is a schematic plan view of the electronic weighing scale 10, figure 1 (b) is a front view of the electronic weighing scale 10 . but in figure 1 In (a), a part of the cover plate 50 is cut away to expose the mounting hole 22, and only the strain generator 32 in the load cell unit 30a provided in the upper left part of the figure is shown, and the cup member 40 is also omitted. icon.

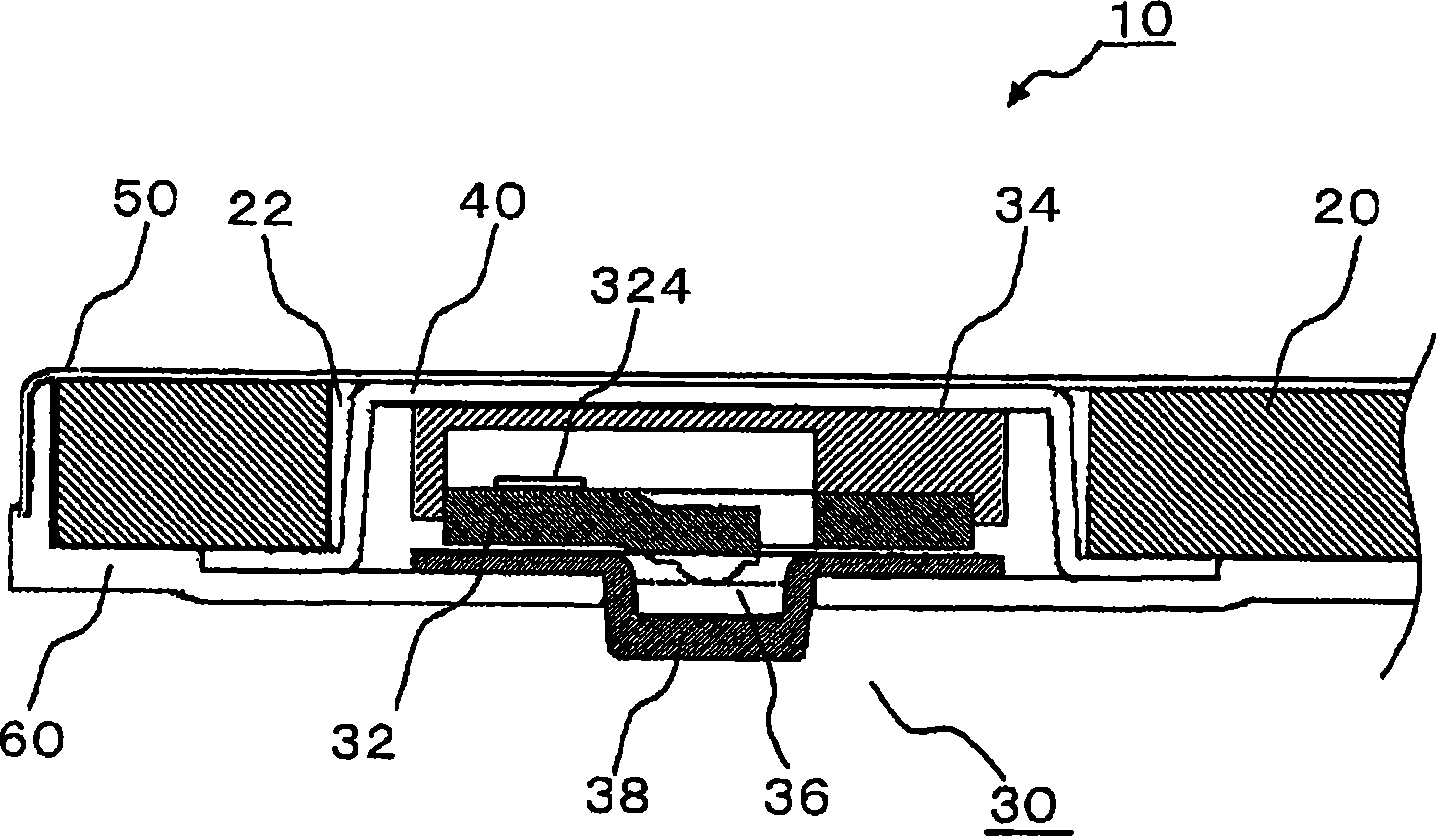

[0034] figure 2 is along figure 1 Section view of II-II i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com