Backlash elimination structure of transmission mechanism

A transmission mechanism and backlash technology, which is applied to mechanical equipment, components with teeth, belts/chains/gears, etc., can solve problems such as difficult mechanism rigidity, limited space or complex structure, and effects of backlash elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

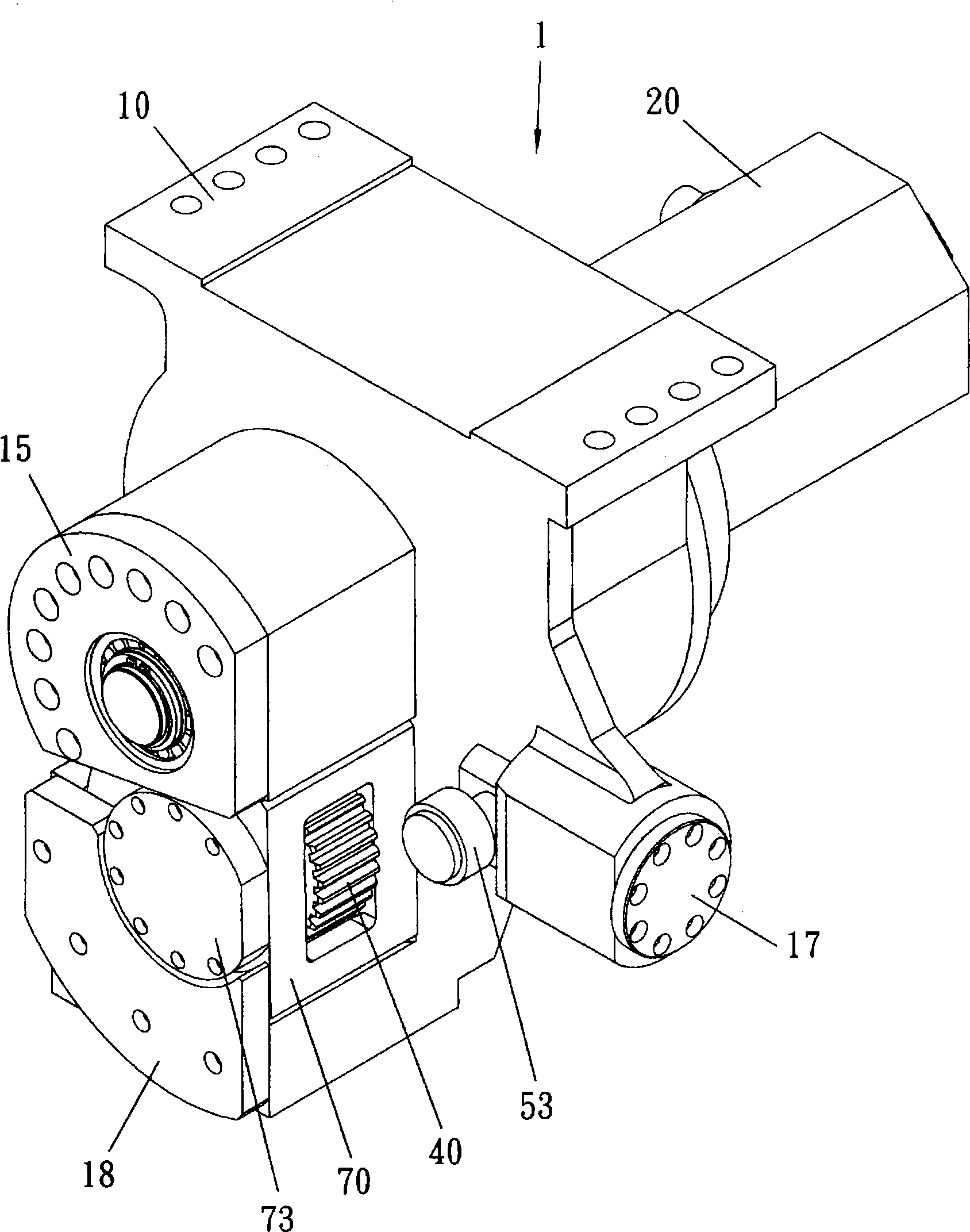

[0018] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

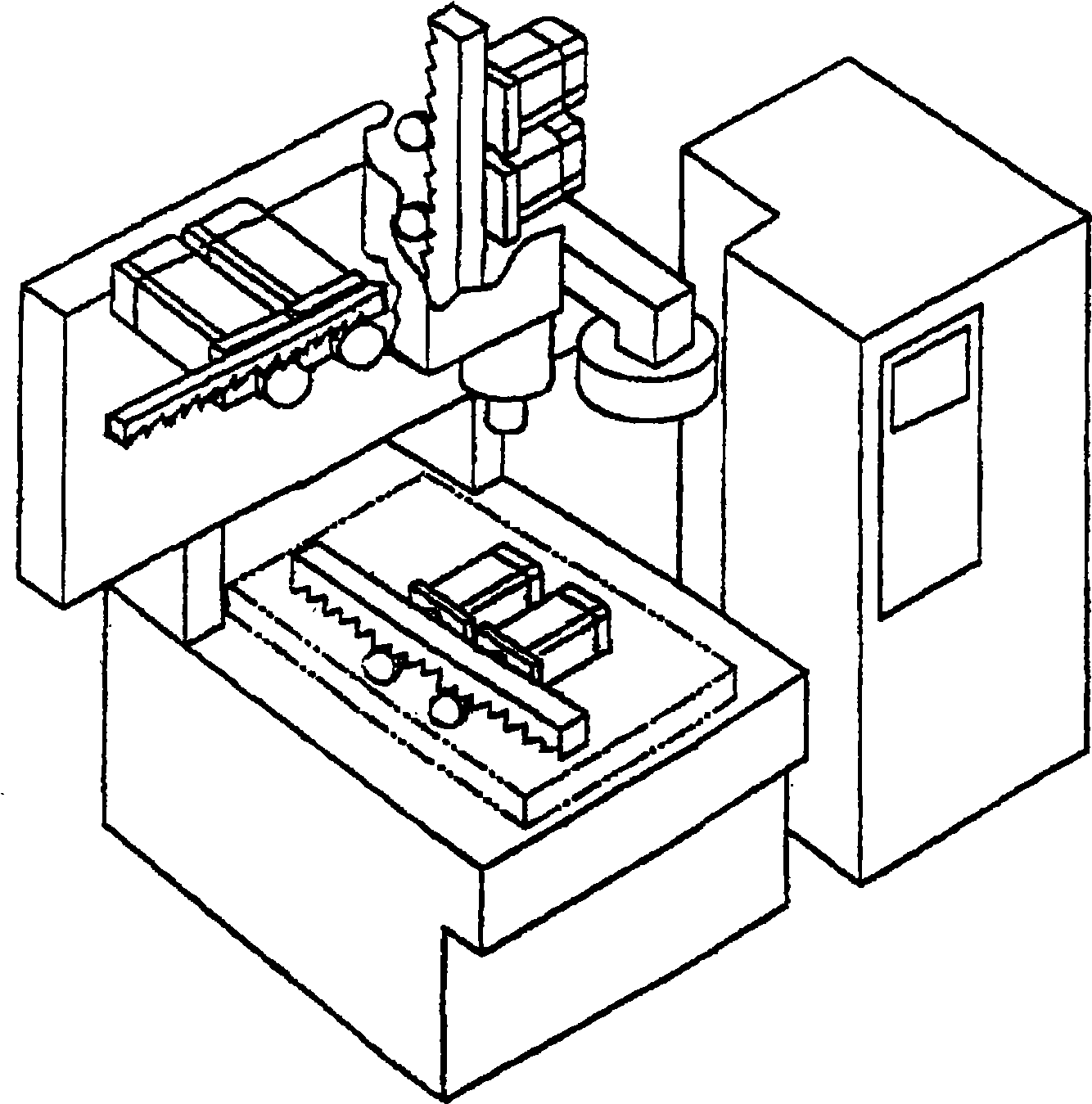

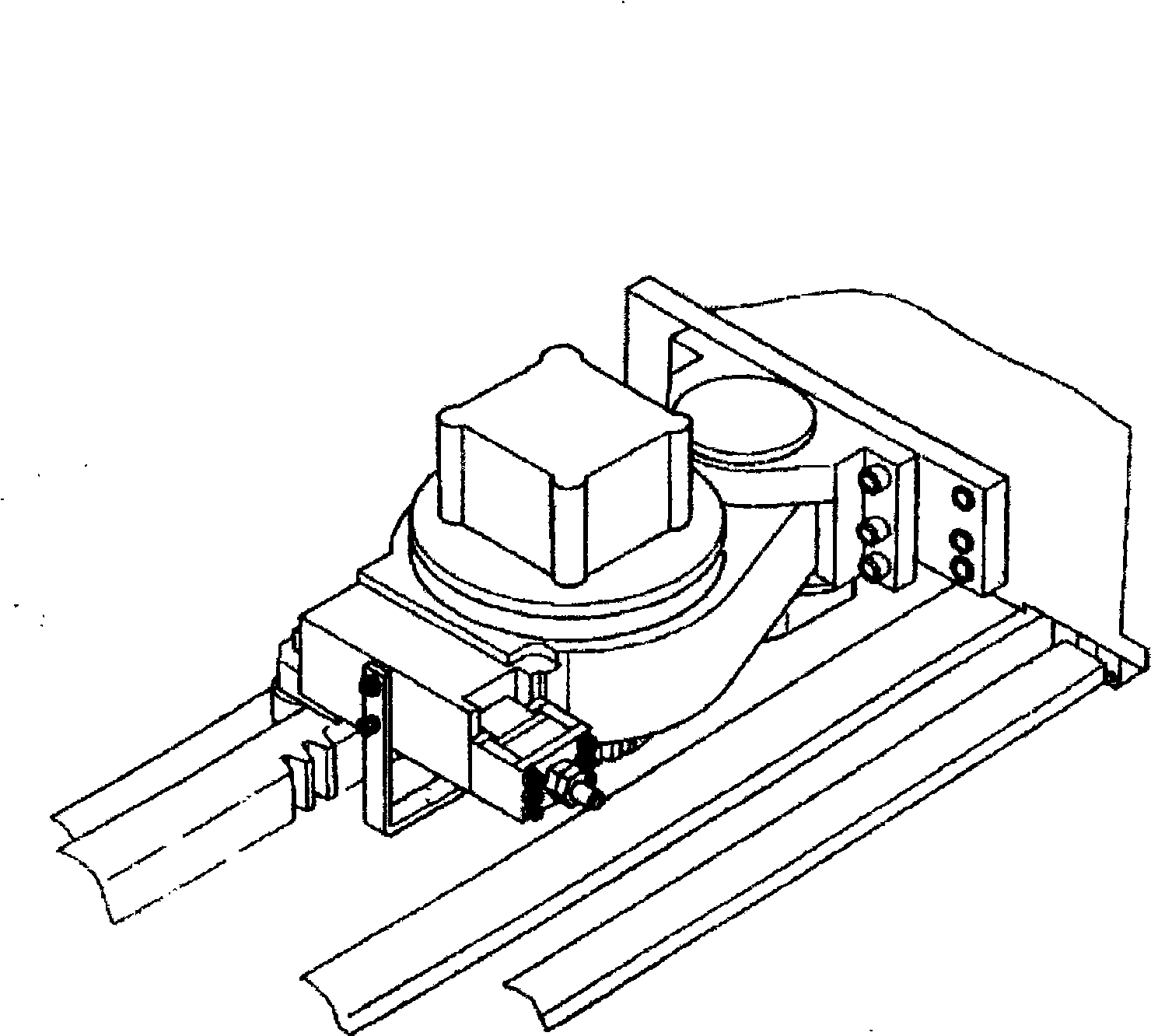

[0019] see Figure 3 ~ Figure 7 As shown, the backlash elimination structure of the transmission mechanism of the present invention is composed of a mechanism body (10), a motor (20), a driving gear (30), a driven gear (40), an elastic unit (50), and a buffer unit ( 60) and other components form a transmission mechanism (1), so that the transmission mechanism (1) can move on a straight or curved rack (2), wherein:

[0020] The mechanism body (10) is provided with a plurality of accommodation parts (11, 12, 13, 14) on its peripheral inner edge respectively, and its first accommodation part (11) is located at the center and is in the shape of In the through-hole structure in the stage configuration, the inner side is for accommodating the driving gear (30), and a cover plate (15) is locked to fix it. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com