Nitrogen coated slow release fertilizer

A coating and fertilizer technology, applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of non-degradable coating, environmental pollution, and short release period, and achieve good slow-release application effect, high fertilizer content, and long release period effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

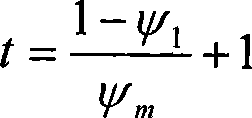

Method used

Image

Examples

Embodiment 1

[0021] Add granular industrial urea with a particle size of 2.5 to 3.5mm into the drum coating equipment, and keep the granular urea in a flowing state, and keep the temperature of the granular urea in the drum at 90°C. Spray the aqueous solution of urea-formaldehyde resin prepolymer (urea-formaldehyde resin prepolymer is prepared by reacting urea and formaldehyde with a urea:formaldehyde molar ratio of 1:1.6) slowly on the surface of granular urea, and spray until the quality of the urea-formaldehyde resin coating reaches the final product 24% of the total mass of nitrogen-coated slow-release urea (thickness is about 175 μm), when the surface is viscous, add excess calcium carbonate (particle size 3 μm) to make the surface of the coating stick to a layer of calcium carbonate, and then fully dry Remove the water in the coating, fully solidify the urea-formaldehyde resin in the coating, sieve and remove the unadhered calcium carbonate, and obtain the nitrogen coated slow-release...

Embodiment 2

[0023] Add granular industrial urea with a particle size of 2.5 to 3.5mm into the drum coating equipment, and keep the granular urea in a flowing state, and keep the temperature of the granular urea in the drum at 90°C. Spray the aqueous solution of urea-formaldehyde resin prepolymer (urea-formaldehyde resin prepolymer is prepared by reacting urea and formaldehyde with a urea:formaldehyde molar ratio of 1:1.6) slowly on the surface of granular urea, and spray until the quality of the urea-formaldehyde resin coating reaches the final product 22% (thickness is about 158 μ m) of the total mass of nitrogen-coated type slow-release urea, when the surface is viscous, add excessive nano-calcium carbonate (particle diameter 50nm) so that the coating surface sticks and wraps one layer of nano-calcium carbonate, and then Fully dry to remove the water in the coating, fully solidify the urea-formaldehyde resin in the coating, and sieve to remove the unadhered nano-calcium carbonate to ob...

Embodiment 3

[0025]Add granular industrial urea with a particle size of 2.5 to 3.5mm into the drum coating equipment, and keep the granular urea in a flowing state, and keep the temperature of the granular urea in the drum at 90°C. Slowly spray the melamine-formaldehyde resin prepolymer aqueous solution (the melamine-formaldehyde resin prepolymer is prepared by reacting melamine and formaldehyde with a melamine:formaldehyde molar ratio of 1:3) on the surface of granular urea until the melamine-formaldehyde resin Coating quality reaches 20% (thickness is about 140 μ m) of the total mass of final product nitrogen coating type slow-release urea, sprays excessive white carbon black-alumina mixed powder (silica particle diameter 40nm, The alumina particle size is 2 μm, and the mass ratio of silica: alumina is 9:1) so that the surface of the coating is coated with a layer of silica-alumina mixed powder, and then fully dried to remove the water in the coating, and the coating The melamine-formald...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com