Interface booster type electrofluid mechanics method without spinning jet and use thereof

一种无喷丝头、助力型的技术,应用在新型电流体力学领域,能够解决助力作用小等问题,达到大规模地生成应用促进的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

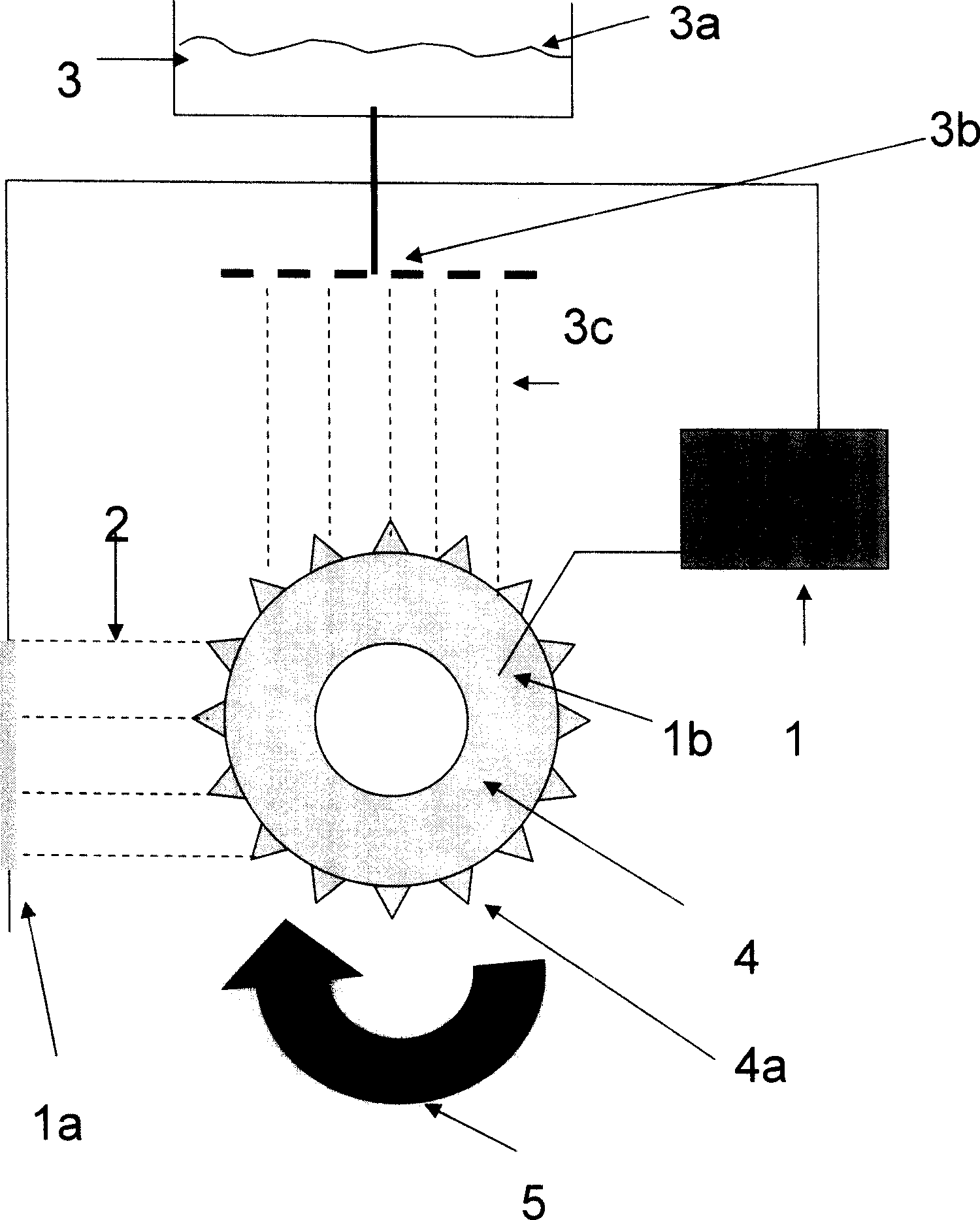

[0053] The electrohydrodynamic method of the centrifugal force type electrohydrodynamic method of spraying the material to be processed without a spinneret such as figure 1 shown. The processed material is sprayed onto the roller 4 through the processed material shower assembly 3b, and when the roller rotates, the showered processed material 3c is subjected to centrifugal force through the sharp protrusion 4a on the edge of the roller. The roller was connected to a high-voltage power source 1 as the working electrode 1b, and the counter electrode was combined with the collection device 1a. When a high-voltage electric field is applied and the roller rotates, the material 3 to be processed is simultaneously subjected to centrifugal force and electrostatic force to form an electric jet 2, thereby processing the material to be processed.

Embodiment 2

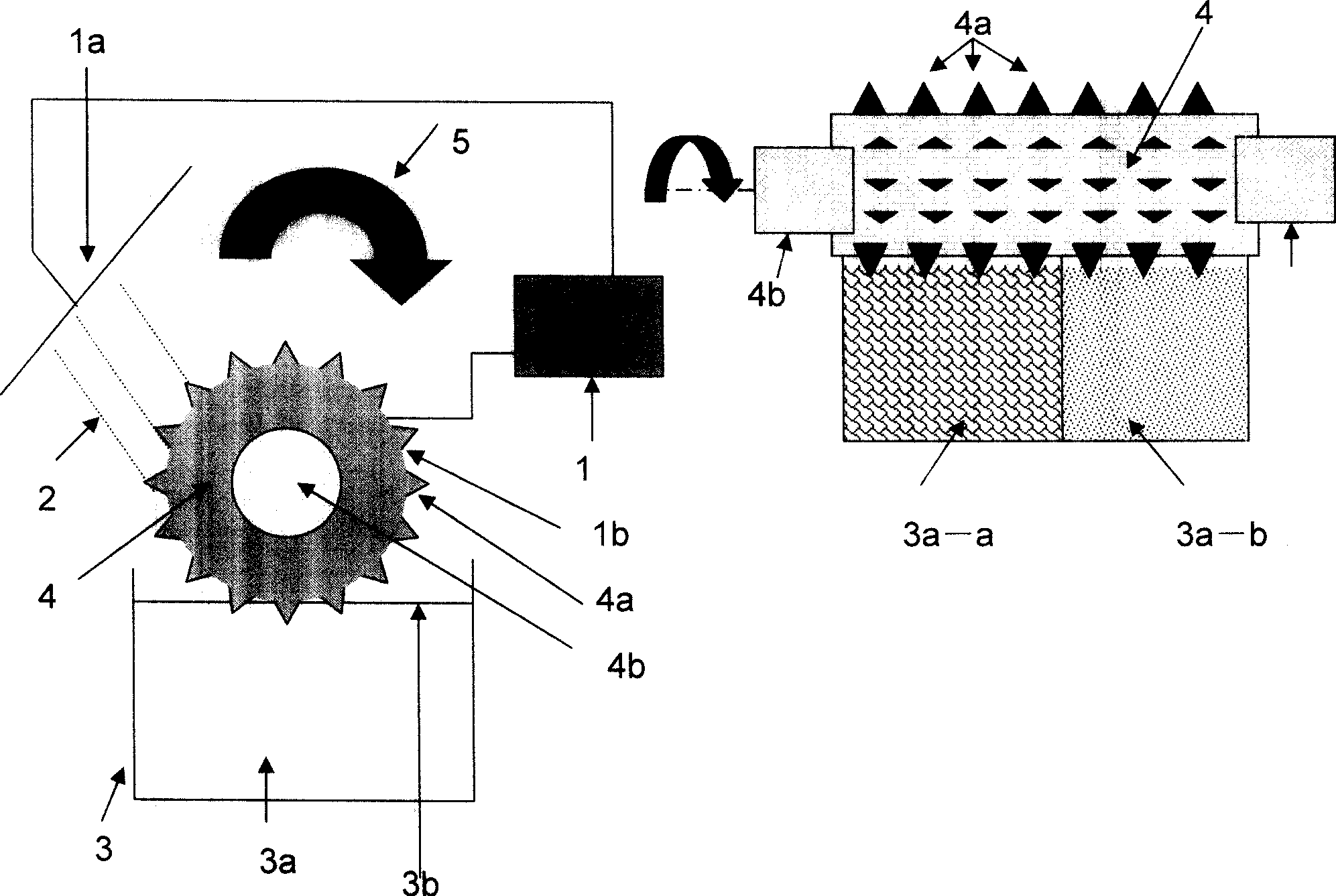

[0055] The electrohydrodynamic method of the roller hitting type electrohydrodynamic method for the material to be processed without a spinneret is as follows: figure 2 Department shown. The fluidized processed material 3a is located in the container 3 below the roller, and when the roller 4 rotates, the processed material adheres to the roller, and receives centrifugal force at the sharp protrusion 4a on the edge of the roller. The roller is connected to a high-voltage power source 1 as the working electrode 1b, and the counter electrode is combined with the collection device 1a. When a high-voltage electric field is applied and the roller rotates, the two processed materials 3a-a and 3a-b are simultaneously subjected to centrifugal force and electrostatic force to form an electric jet 2, thereby processing the two processed materials simultaneously.

Embodiment 3

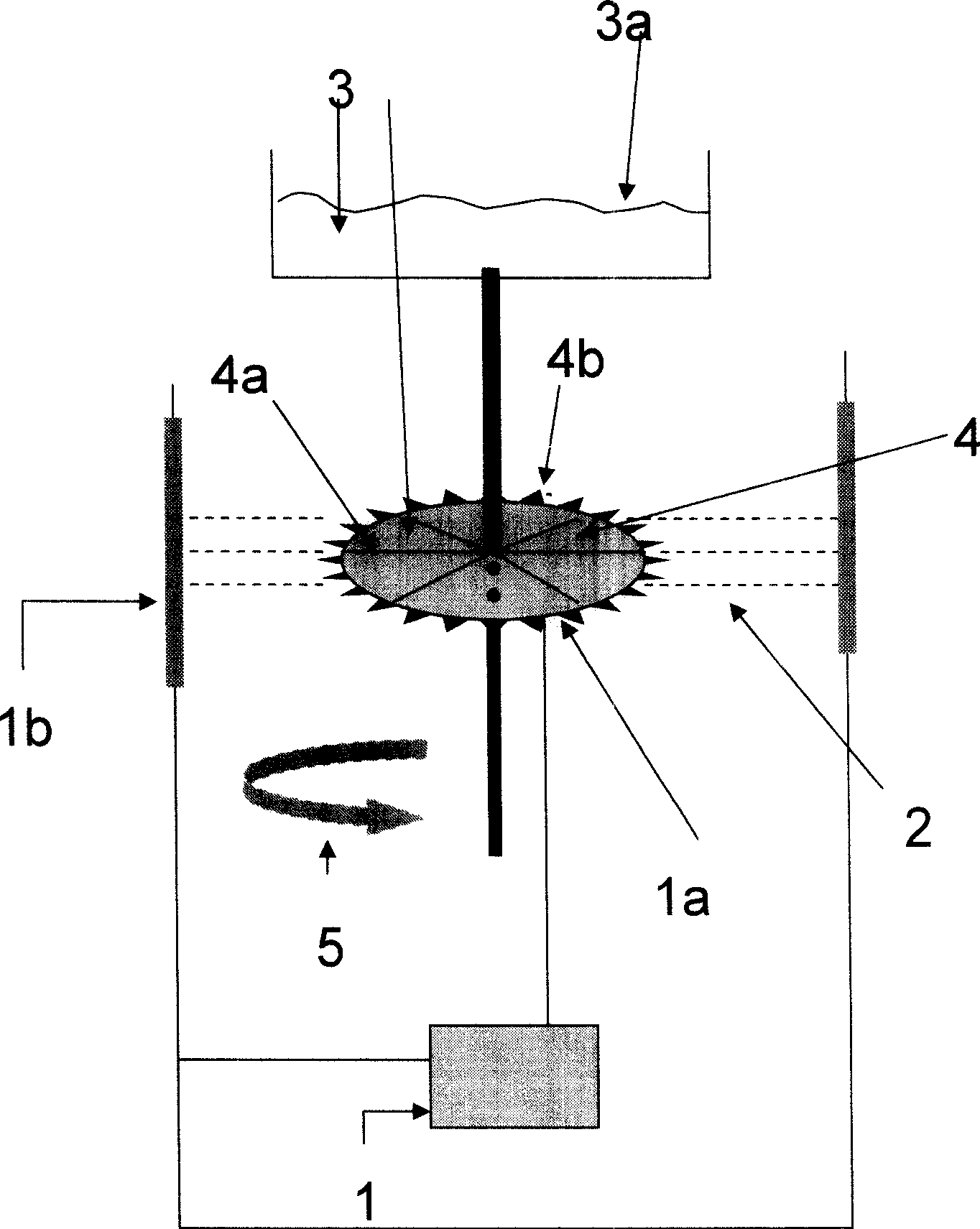

[0057] The system structure of spinnerless rotary disc centrifugal electrohydrodynamic method is as follows: image 3 shown. The fluidized material 3 to be processed is guided to the turntable 4, and when the turntable rotates, the material to be processed goes along the guide groove 4a on the turntable to the sharp protrusion 4b on the edge of the turntable to obtain centrifugal force. Connect the turntable to a high-voltage power source 1 as the working electrode 1b, and the counter electrode is combined with the collection device 1a. When a high-voltage electric field is applied and the turntable rotates, the material 3 to be processed is simultaneously subjected to centrifugal force and electrostatic force to form an electric jet 2, thereby processing the material to be processed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com