Automatic water sprayer for all-terrain irrigation

An all-terrain sprinkler technology, applied in the field of agricultural and horticultural irrigation equipment, can solve problems such as inability to adapt, large water consumption, and poor adjustment, and achieve flexible and convenient adjustment, strong site adaptability, and various spray forms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

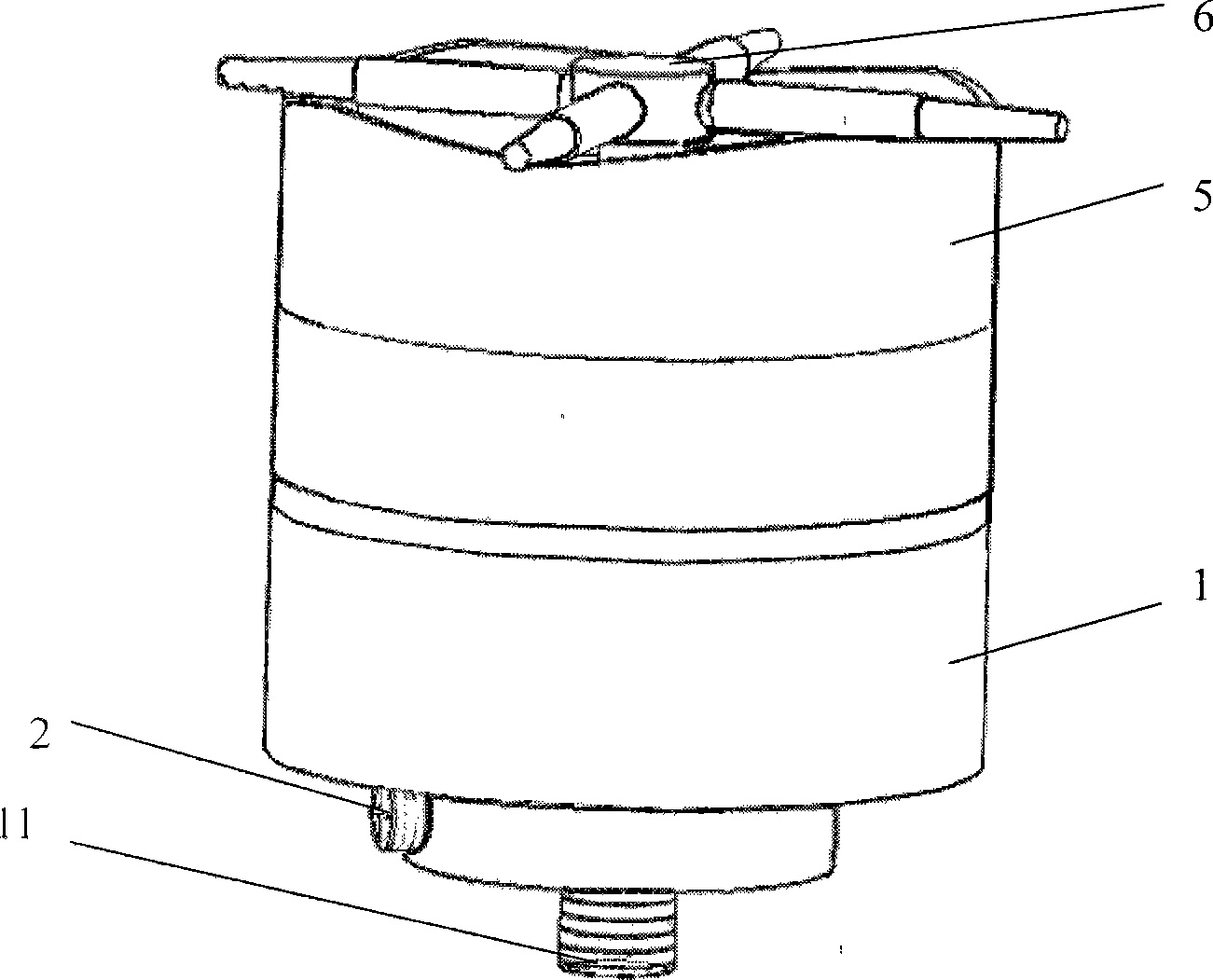

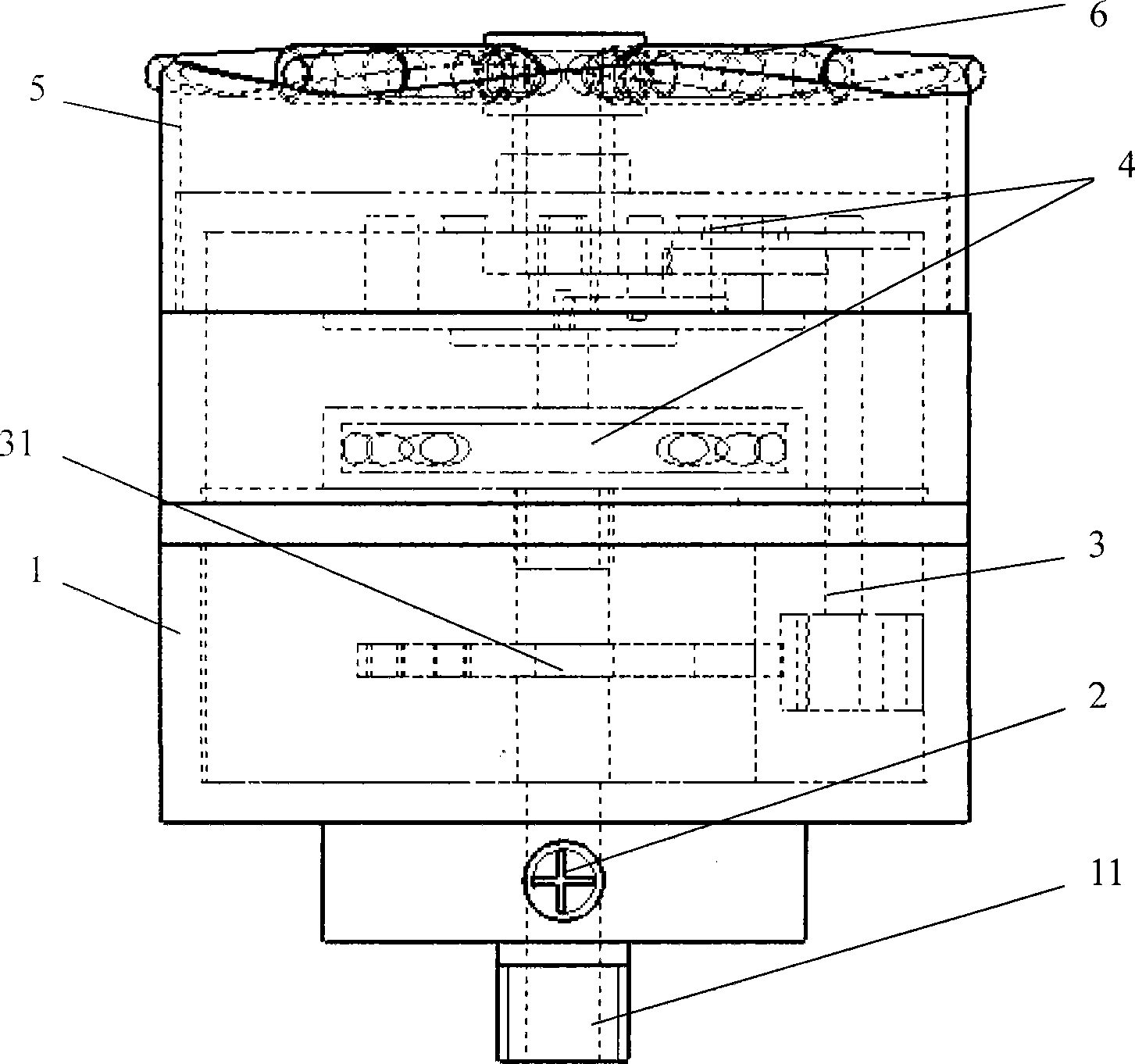

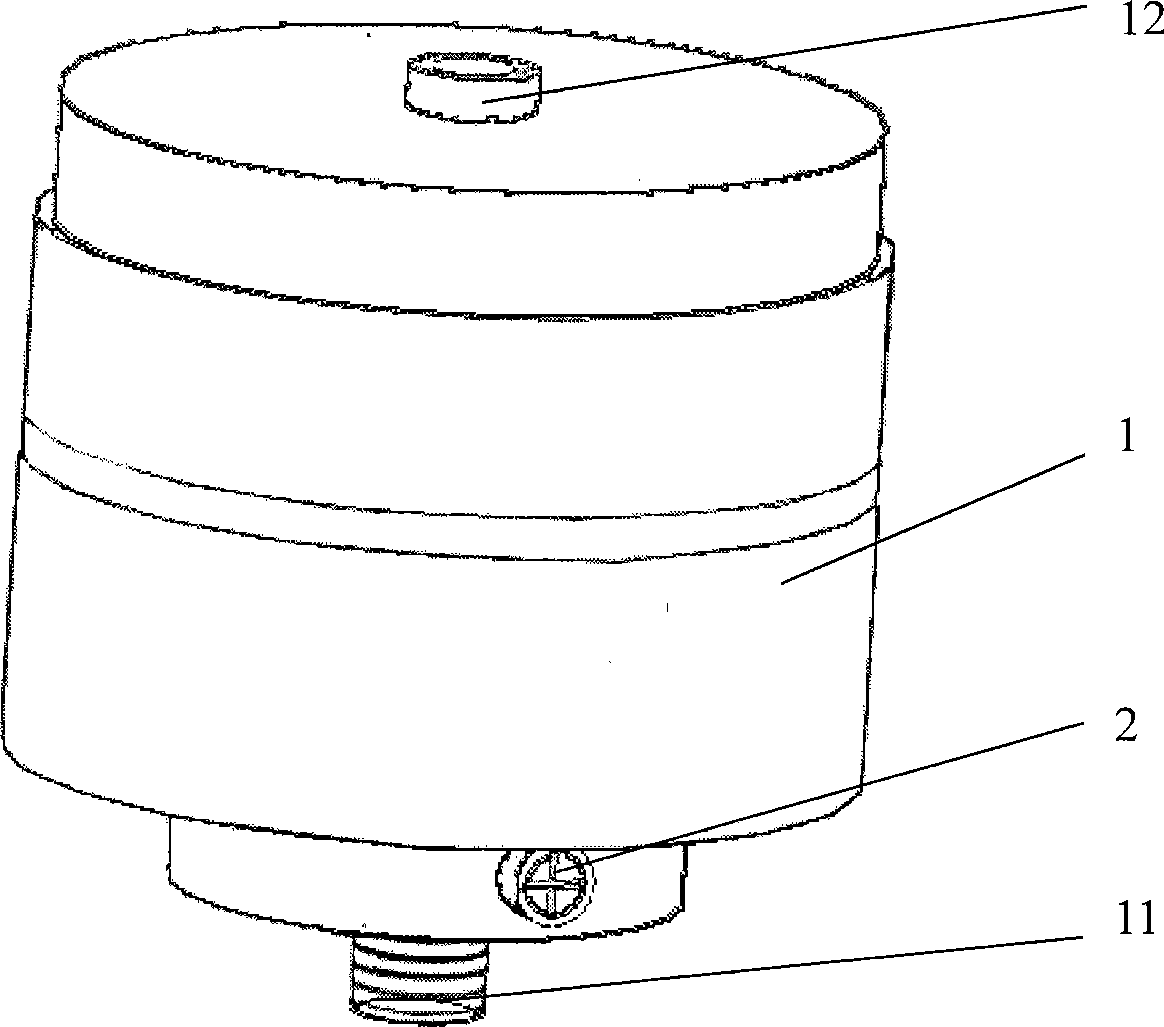

[0028] Figure 1 to Figure 8 Shown is an embodiment of the invention. Such as figure 1 and figure 2 As shown, it includes a housing 1 , a maximum range control valve 2 , an automatic range adjustment mechanism 3 , a drive mechanism 4 , an angle adjustment member 5 and a water spray mechanism 6 . Such as figure 1 and image 3 As shown, the bottom of the housing 1 is provided with a water inlet 11 , and the top is provided with an installation port 12 .

[0029] The maximum range control valve 2, the automatic range adjustment mechanism 3, and the driving mechanism 4 are arranged in the housing 1, wherein the maximum range control valve 2 and the automatic range adjustment mechanism 3 can be arranged before or after the driving mechanism 4 according to the water flow direction. The maximum range control valve 2 is arranged on the water flow pipeline in the housing 1, and adopts an ordinary liquid flow regulating valve, which can be manually adjusted, or rotated or linearly...

Embodiment 2

[0038] Figure 9 Shown is the second embodiment of the present invention, which differs from embodiment one in that: the angle adjusting member (5) is adjustable, such as Figure 9 As shown, it is formed by nesting of fixed ring (53) and adjustable ring (54). The fixed ring (53) is outside and has a fixed supporting effect; the adjustable ring (54) is inside and is distributed with adjustable rods (55) that can advance and retreat between the fixed ring (53), such as adjusting screws. The adjusting rod (55) passes through the fixed ring (53), and one end thereof is connected on the side of the adjustable ring (54). The adjustable ring (54) is elastic, and the outer surface of the nozzle (62) rests on the top end of the adjustable ring (54). When in use, by changing the telescopic distance of the adjusting rod (55) at some positions, the elastic adjustable ring (54) is partially deformed to have a certain shape, thereby changing the far and near contact distance with the nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com