Monitoring system and method for service life of test equipment

A technology for testing equipment and monitoring systems, applied in the directions of registration/indication of machine work, registration/instruction, instruments, etc., which can solve problems such as inability to test the service life of equipment, inaccurate statistical data of test equipment, and increase the difficulty of statistics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

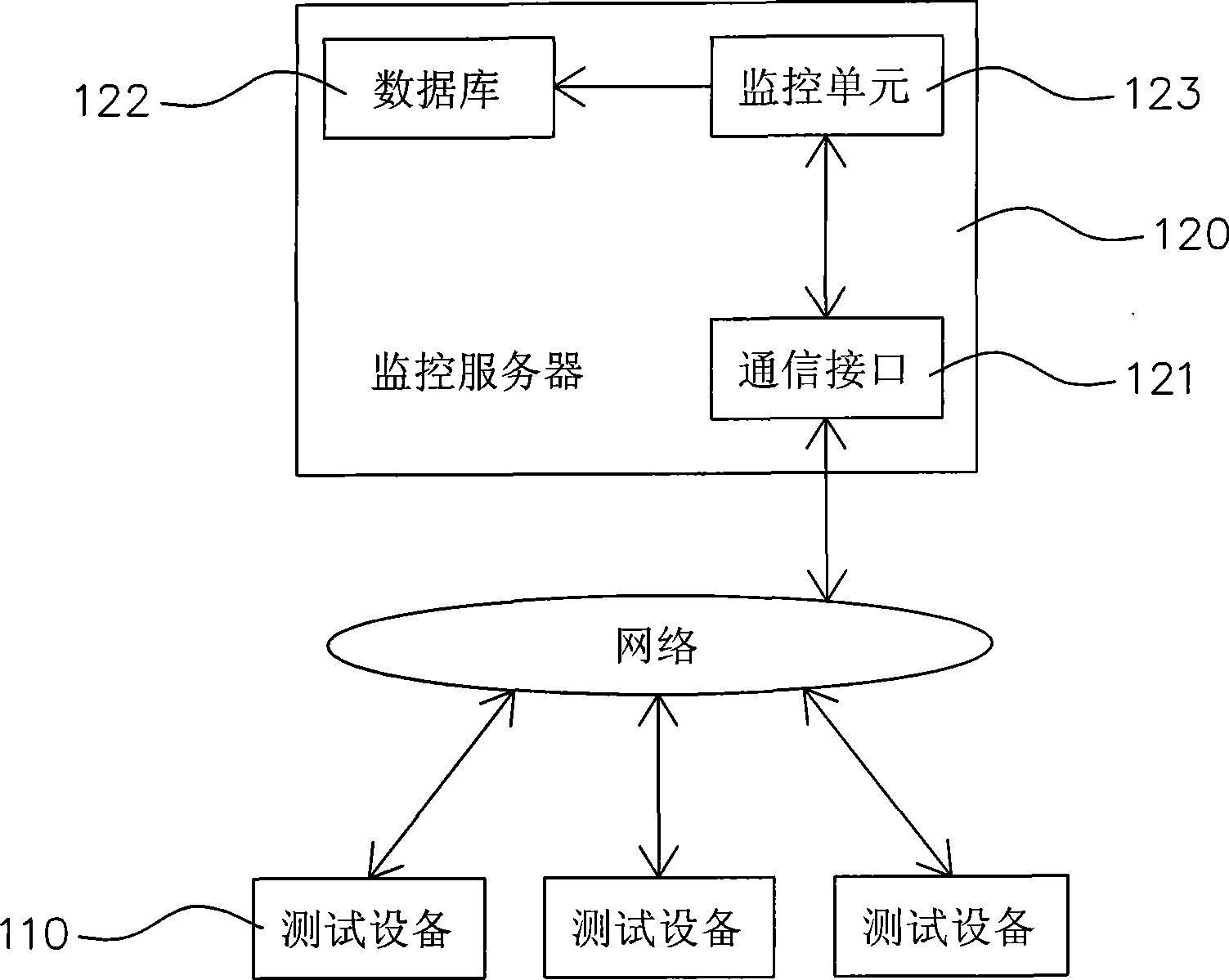

[0022] Please refer to figure 1 shown. In the production and manufacturing process of the product, it is necessary to use various or multiple testing tools to test the product in various aspects. In this embodiment, each testing tool is collectively referred to as testing equipment 110 . Each testing device 110 is connected to a monitoring server for monitoring the service life of each testing device 110 through the network.

[0023] For example, the test equipment 110 is a computer terminal loaded with a test program; when the product is tested, the bar code representing its identity on the product is read through the optical identification element, and the test program is run to test; of course, the computer terminal can also Set up a calculator to count the number of times the test program is run, and use this as a basis to count the number of times the test equipment is used. Here, every time a test is completed, the test device 110 adds 1 to the data of the number of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com