High speed tablet press

A tablet press, high-speed technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems affecting tablet quality, changes in pre-compression pressure, etc., to improve the level of automation control and ensure quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

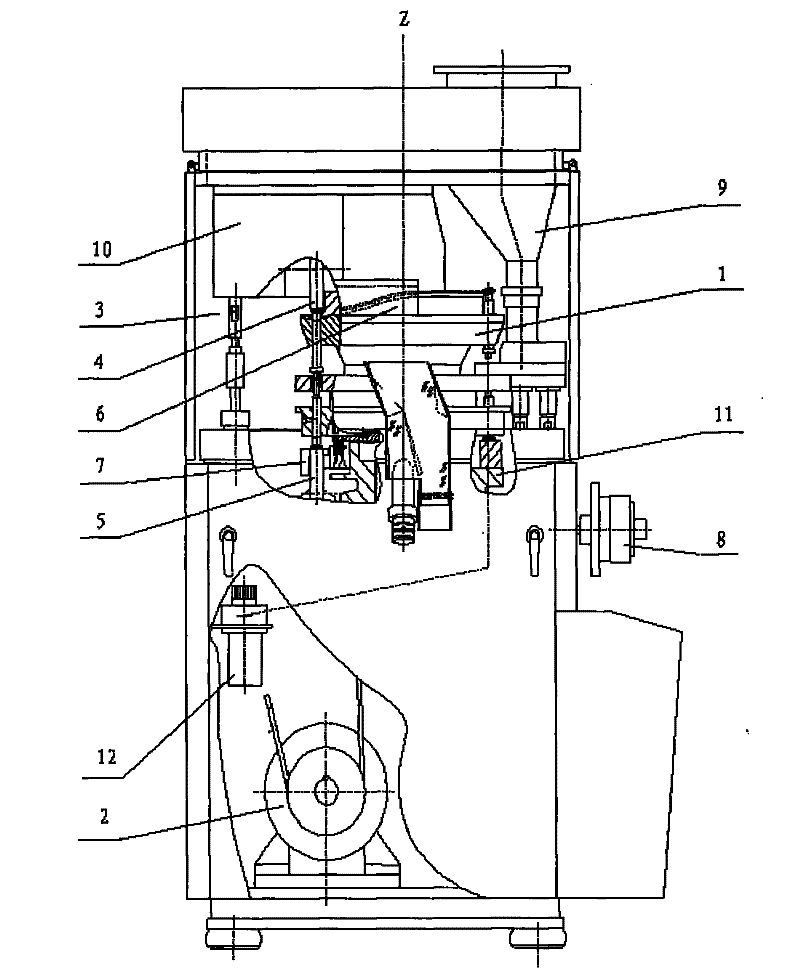

[0040] This embodiment is a single discharge model, such as figure 1 and figure 2 As shown, the high-speed tablet press of the present embodiment is a high-speed rotary tablet press, including:

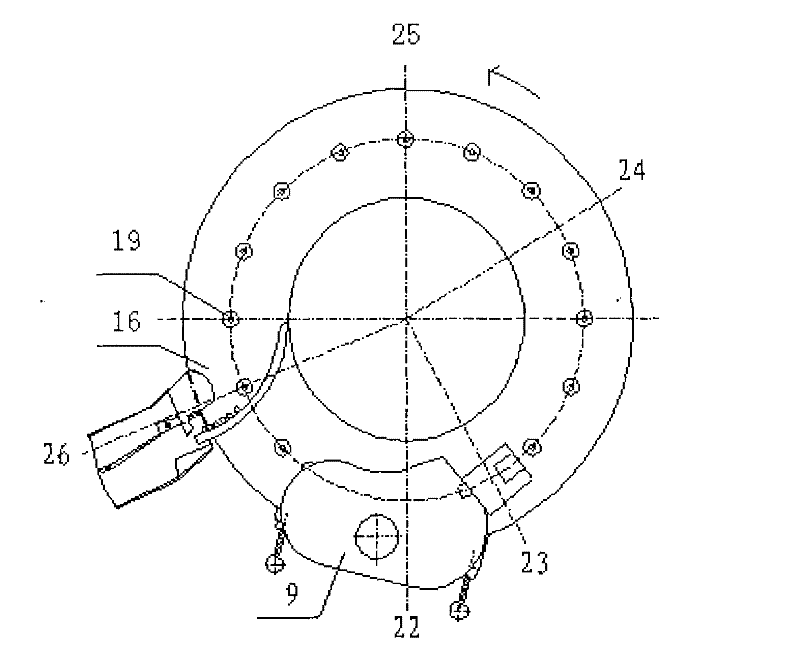

[0041] The turntable 1 includes a middle punching plate 16, an upper punching plate 15 respectively arranged above the middle punching plate 16, and a lower punching plate 17 arranged below the middle punching plate 16; mod 19;

[0042] The feeding device 9 is arranged above the middle punching plate 16, and is used to add formula materials into the middle mold 19; the transmission mechanism 2 is used to drive the turntable 1 to rotate around the vertical axis Z.

[0043] The press forming mechanism 3 includes multiple pairs of upper punch rods 18 and lower punch rods 20 that are respectively held on the upper punch plate 15 and the lower punch plate 17 and can slide up and down relatively reciprocatingly; 20 a pair of punches at opposite ends.

[0044] The transmission mechanism...

Embodiment 2

[0057] The difference between this embodiment and embodiment 1 is that, as Figure 6 As shown, it is a schematic diagram of the work flow station of the model for pressing the double-layer tablet. The tablet press for making the double-layer tablet has the first layer feeding station 221 of the double-layer tablet model, the double-layer tablet The first layer quantification station 231 of the ply model, the first ply pre-pressing station 241 of the double-layer model, the first layer sampling station 261 of the double-layer model; the second layer of the double-layer model Layer feeding station 222, double-layer sheet model second layer quantitative station 232, double-layer sheet model double-layer sheet pre-pressing station 242, double-layer sheet main press forming station 252, double-layer sheet output Sheet station 262, the first ply feeding device 91 of the double-ply machine located at the first ply feeding station 221, the second layer of the double-ply machine locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com