Corrosion-resistant large-specific gravity titanium alloy sphere and manufacturing method thereof

A manufacturing method and technology of titanium alloy, applied in the direction of lift valve, valve details, engine components, etc., can solve the problems of ball damage, short service life, poor seawater corrosion resistance, and poor erosion resistance in special ball valves for lifting equipment. Achieve the effect of improving service life, enhancing reliability and performance, and achieving obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

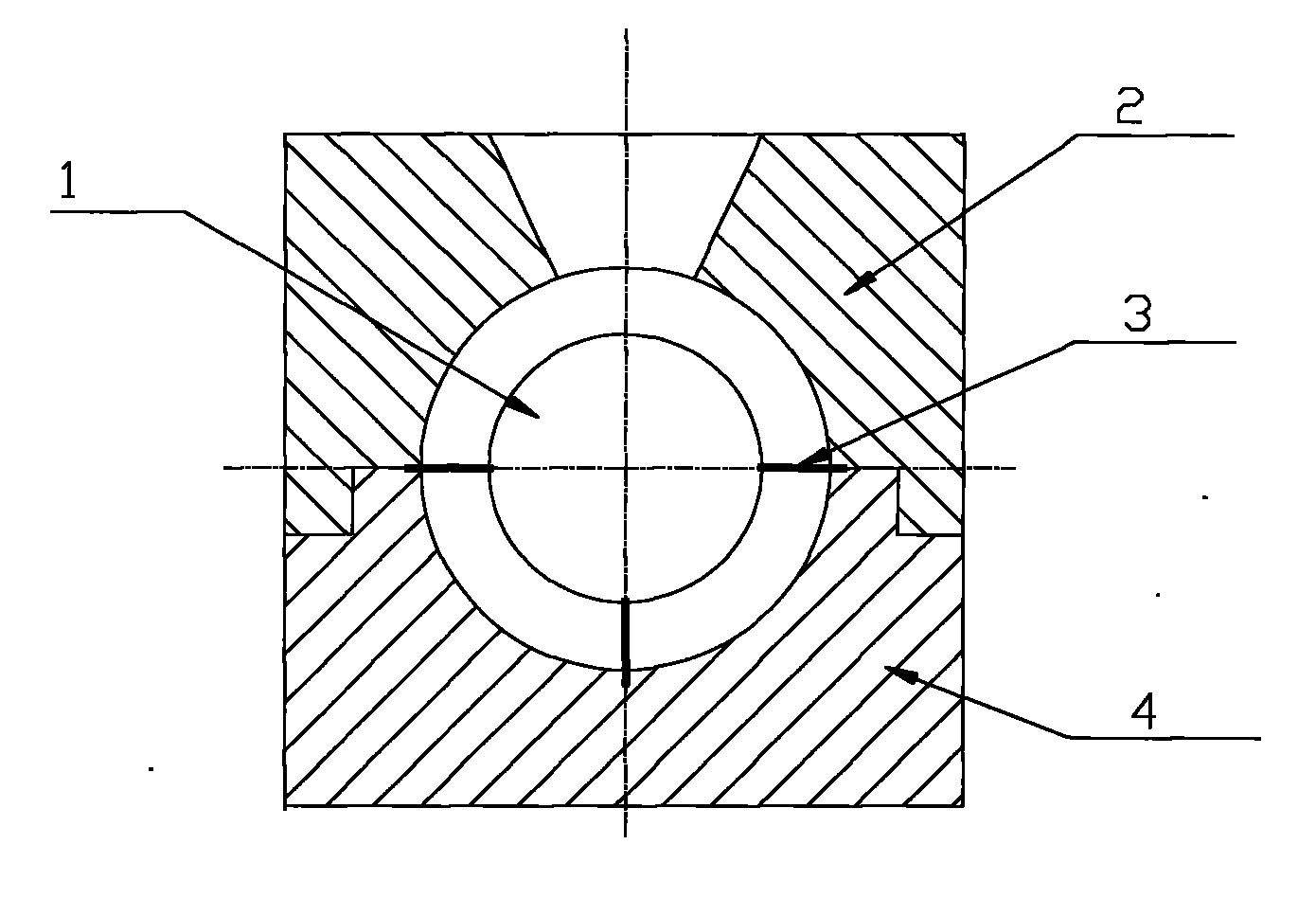

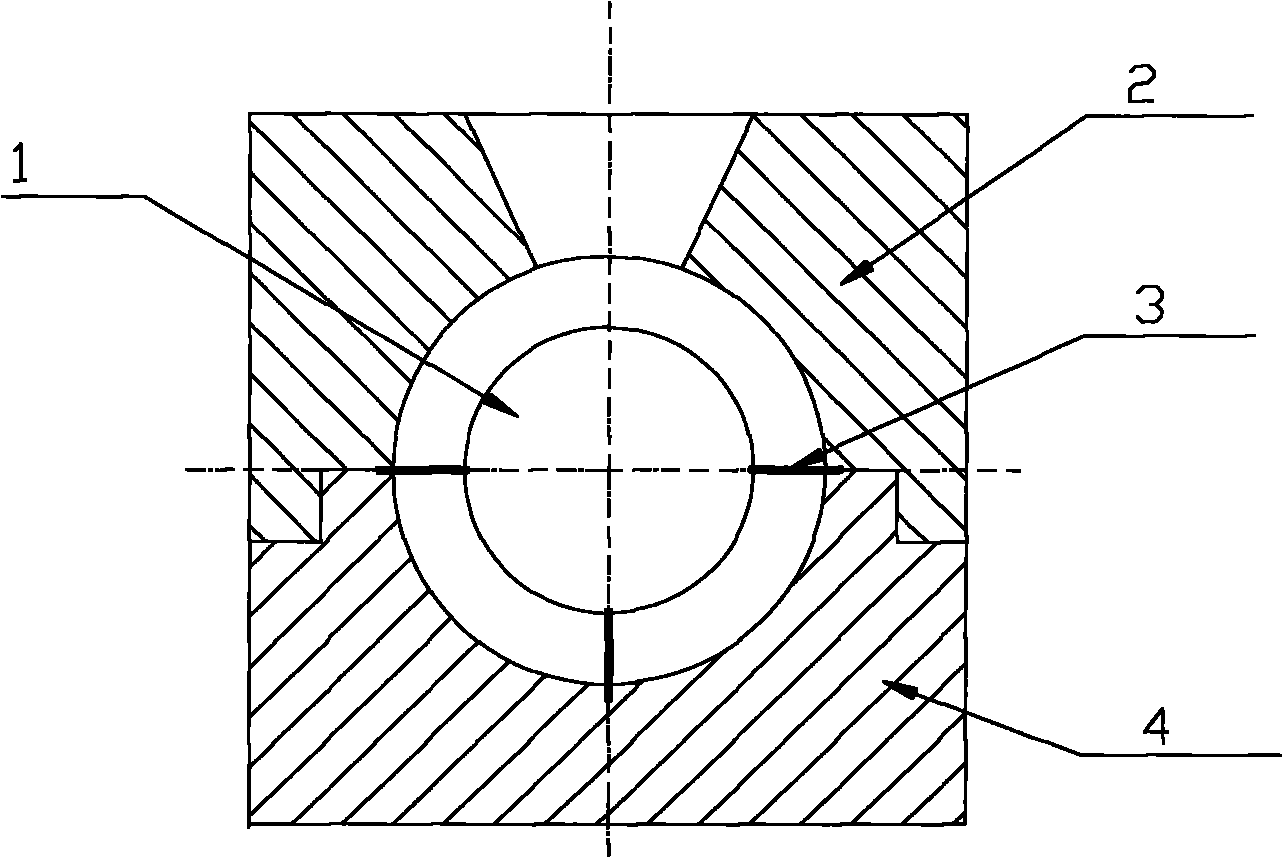

[0020] Manufacturing diameter The inner ball of the floating ball valve for boats. The sphere consists of two parts: the center is the diameter Metal lead, the outside is TC4 titanium alloy with a shell wall thickness of about 2mm. The density of TC4 titanium alloy is 4.45g / cm 3 , lead density 11.34g / cm 3 , through the diameter The surface layer of the metal lead ball is covered with titanium alloy, and the density of the ball is 8.9g / cm 3 , which can better meet the density requirements of the special ball valve for lifting equipment.

[0021] The sphere is manufactured as follows:

[0022] (1) Two sets of graphite molds are manufactured: one set requires the internal aperture of the graphite mold to be The mold is used for casting Shot put, after the casting is completed, the Shot puts are processed into higher precision shot put. Another set requires that the internal aperture of the graphite mold is Before casting, the higher precision The shot is fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com