Novel exhausting pipe of engine

A technology for engines and exhaust pipes, applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve the problems of unsmooth exhaust, difficult exhaust gas discharge, poor sound absorption effect, etc., so as to prolong the service life and prevent accidents Rust, good sound-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing of description:

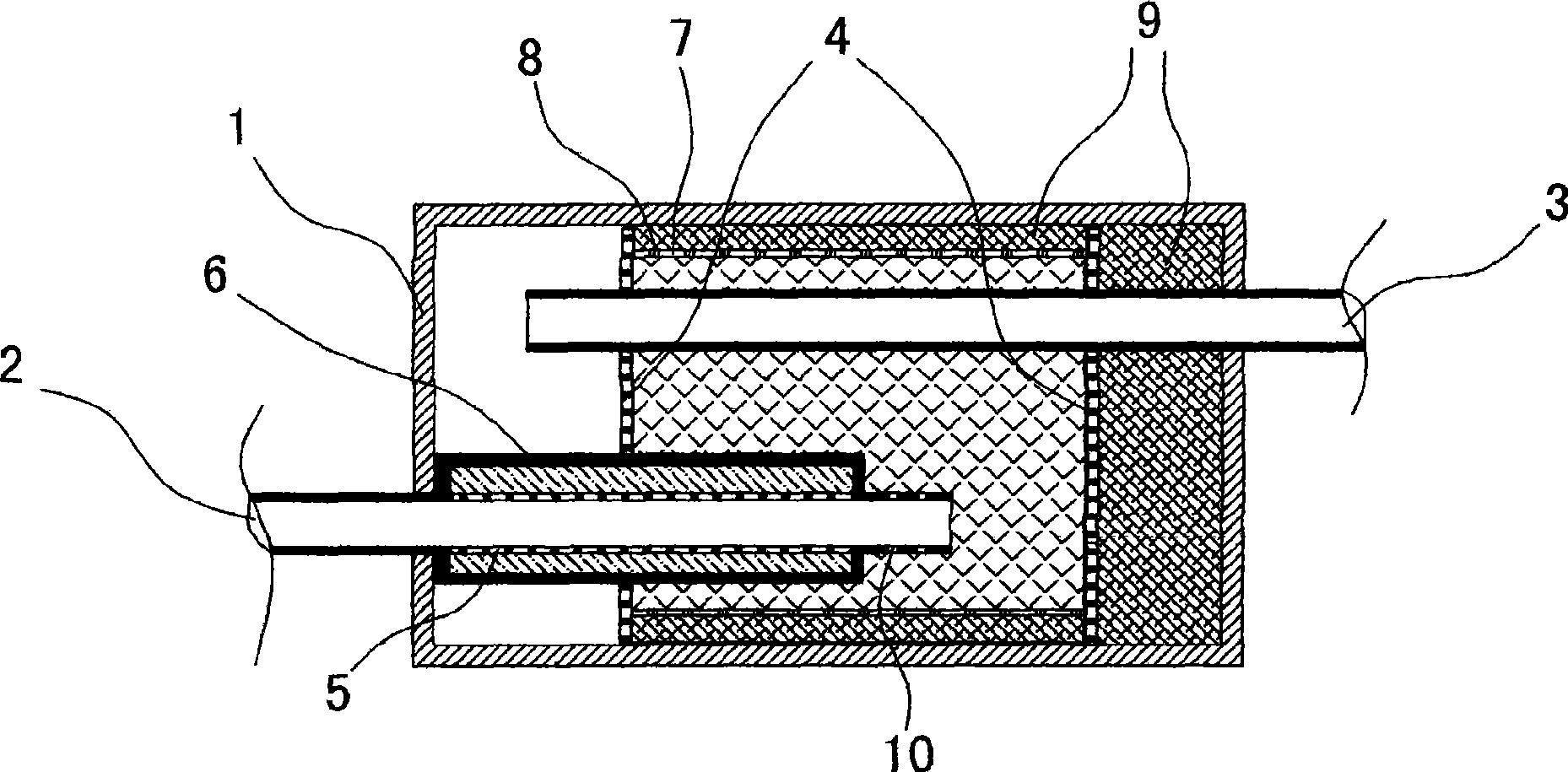

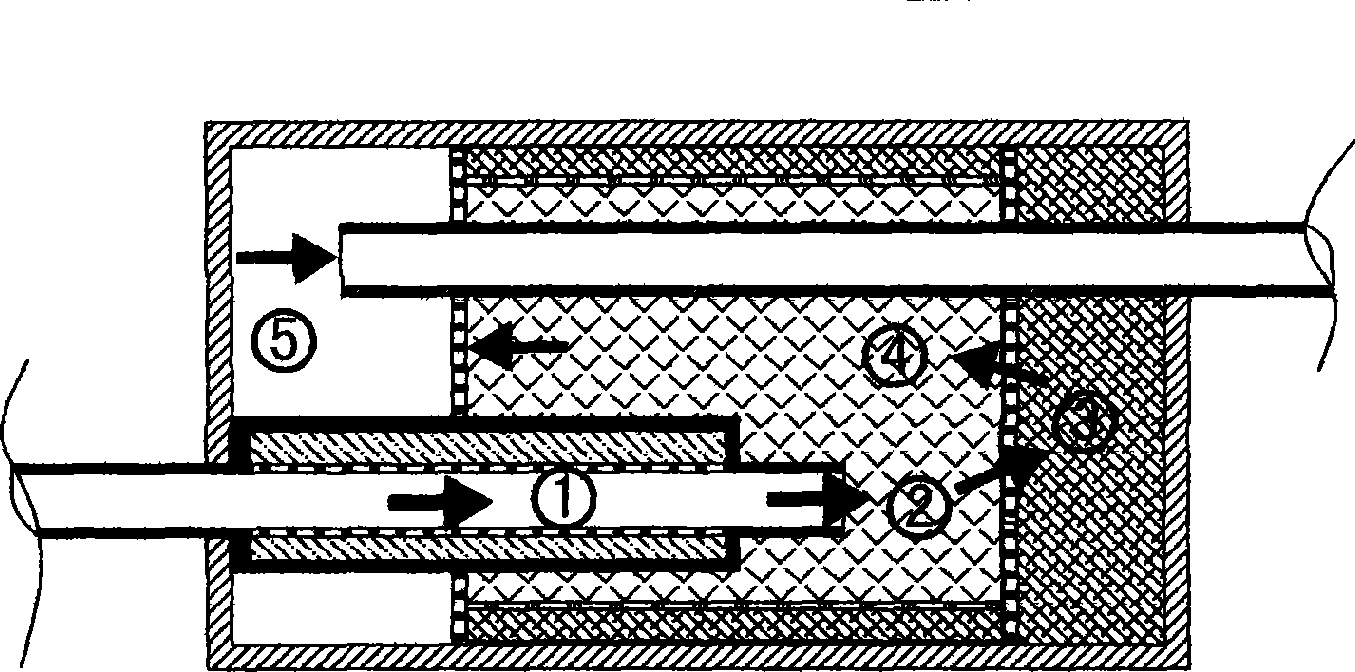

[0016] as attached figure 1 , attached figure 2 As shown, a novel engine exhaust pipe includes a drum core 1, an air intake hole 2, and an air outlet hole 3. The spacer net plate 4 forms a sealed hollow tube structure of a plurality of anechoic chambers. The anechoic chamber formed by a plurality of spacer net plates is provided with a net plate 8 with a mesh 7 and a sound-absorbing cotton 9 extending to the hollow of the drum core. There are many sound-absorbing holes 5 around the end of the air-intake hole in the tube structure, and a separately sealed hollow chamber 6 is arranged on the outer periphery of the position where the air-intake hole is provided with the sound-absorbing hole. The empty chamber is filled with sound-absorbing cotton to form a separate Sealed anechoic chamber.

[0017] A net plate with mesh and sound-absorbing cotton are also ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com