Spraying apparatus for construction coating

A technology for spraying devices and architectural coatings, which is applied in construction, building structure, etc., can solve the problems of high manufacturing cost, heavy mechanical parts, low work efficiency, etc., and achieve the effects of convenient, fast construction and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

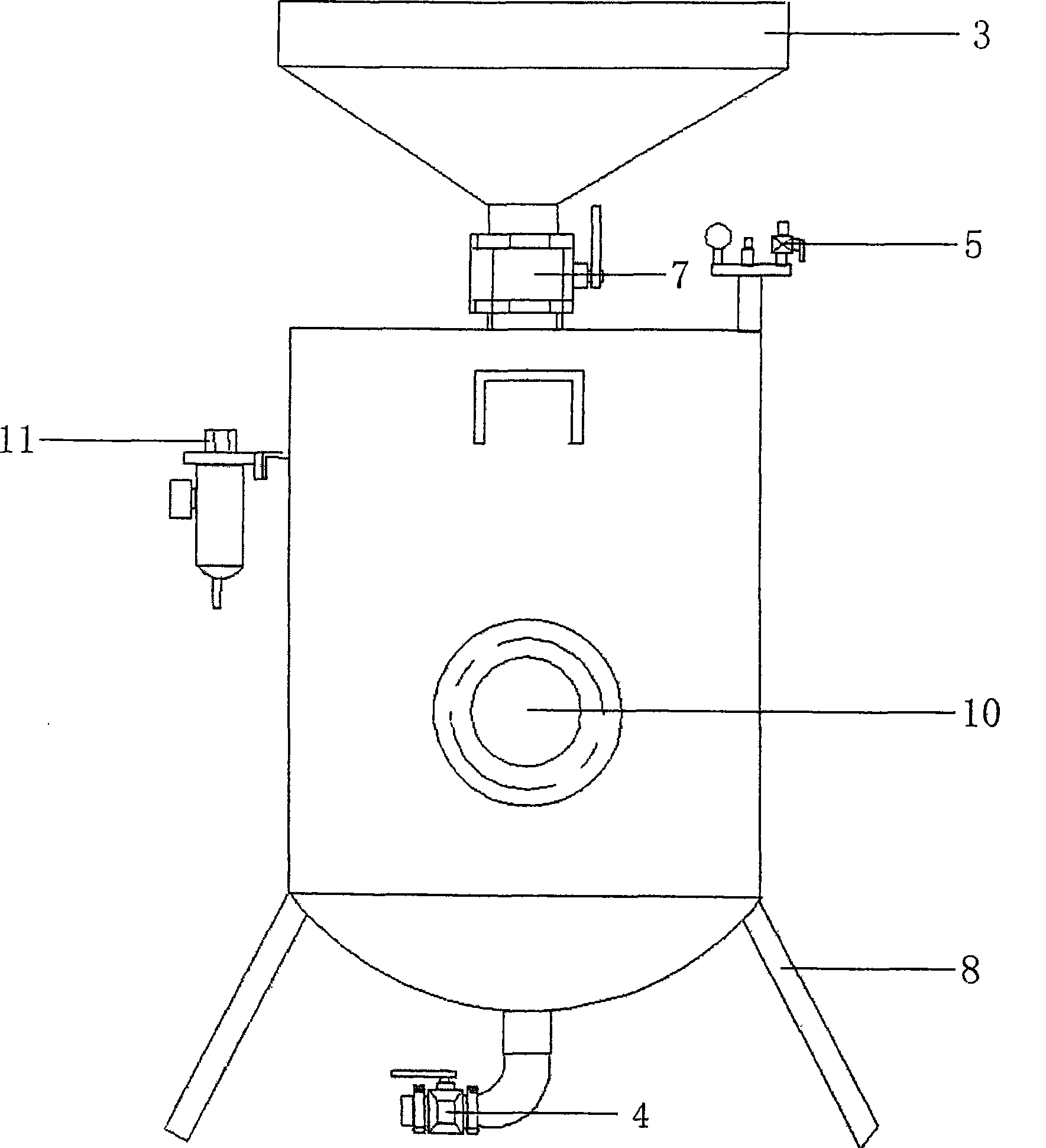

[0010] as attached figure 1 As shown, the present invention mainly consists of a pressure storage tank 1, a pre-storage tank 2, and a hopper 3. The pressure storage tank 1 is a closed tank body, and a discharge valve 4 is installed at the lower end of the pressure storage tank 1, and the paint flows out through the discharge valve 4, and a high-pressure gas inlet valve 5 is also installed at the upper end of the pressure storage tank 1 , the high-pressure gas enters the pressure storage tank 1 from the intake valve 5 . The pressure storage tank 1 is connected with the pre-storage tank 2 through the airtight valve 6, the pre-storage tank 2 is above the pressure storage tank 1, and the upper end of the pre-storage tank 2 is connected with the hopper 3 through the feeding valve 7, The paint enters the pre-storage tank 2 from the feed hopper 3 through the feed valve 7, and when the airtight valve 6 and the feed valve 7 are all closed, the pre-storage tank 2 also becomes an airtig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com