A ceramic sanitary fixture

A technology for sanitary ware and ceramics, applied in the direction of ceramic forming machines, die-casting molds, manufacturing tools, etc., can solve the problems of increasing the cost of finished products and reducing the standardization level of structural components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

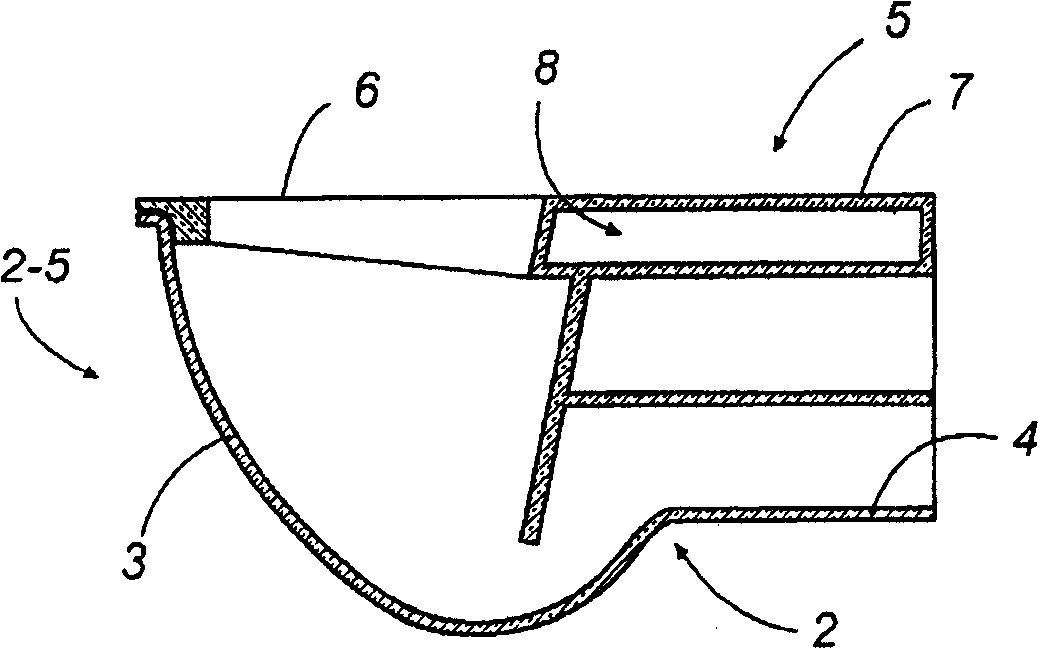

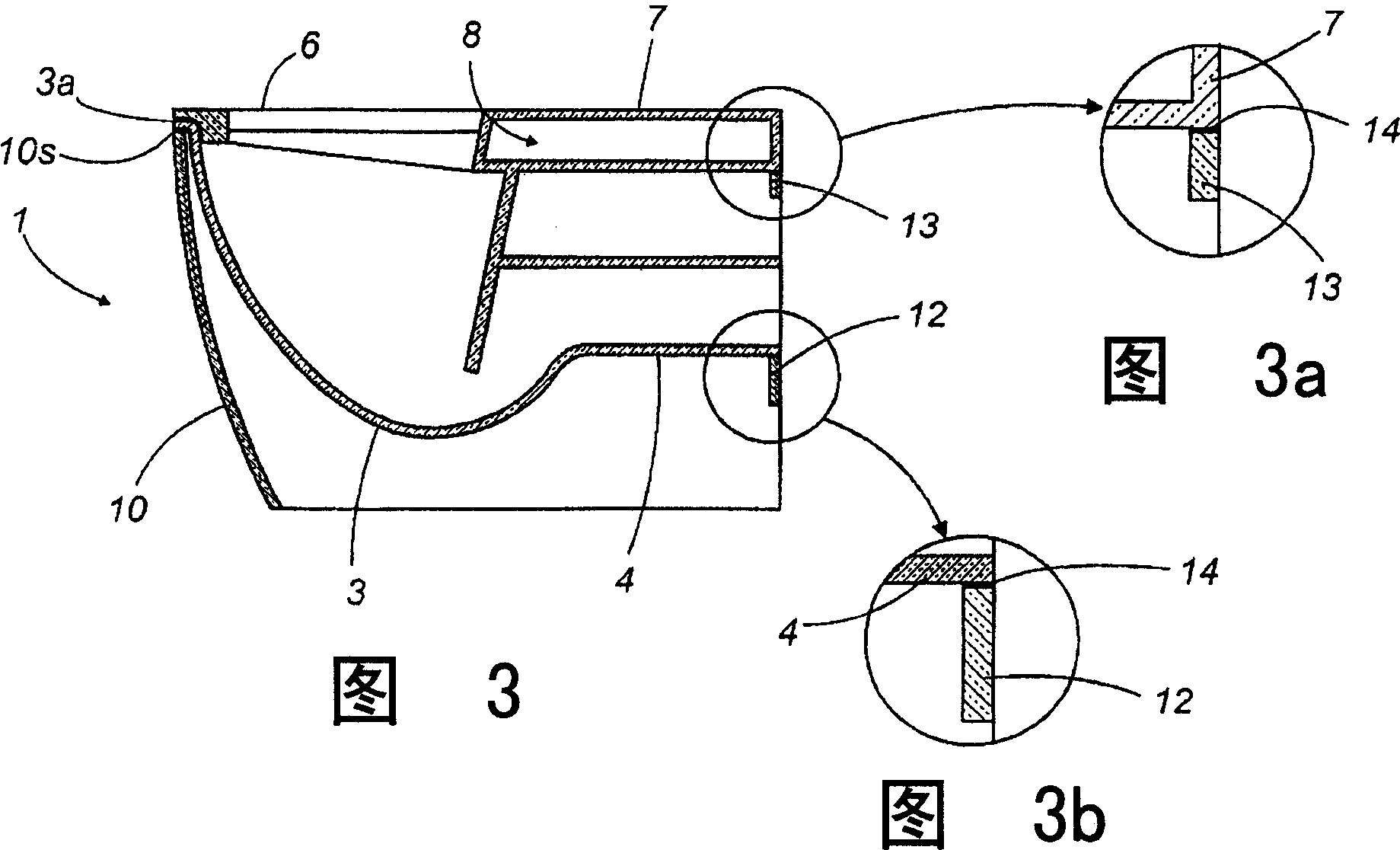

[0027] With reference to the accompanying drawings, specifically figure 1 To 3, the sanitary ware according to the present invention is a type made of a ceramic material by pouring a watery state (called "slime") into a porous resin mold.

[0028] More specifically, the sanitary ware consisting of a ceramic flush toilet 1 basically includes:

[0029] - a first bottom part 2 comprising a liquid collecting basin 3 and a siphon part 4 for draining the liquid;

[0030] - A second top part 5 or seat, consisting of a front 6 forming the upper edge of the basin 3 and a rear extension 7 comprising a channel 8 for the passage of fluid.

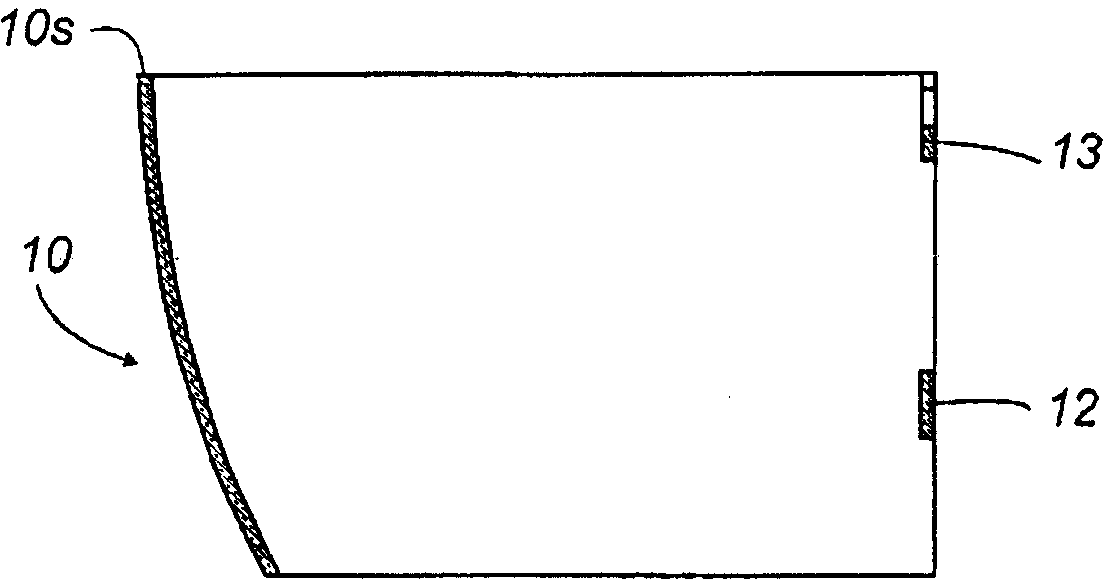

[0031] As is clearly shown in Figure 3, the first and second parts 2 and 5 are made in one piece in a mold to form a single part 2-5, and there is also a third cover in which the single part 2-5 can be shrouded. Part or outer housing 10, the individual parts 2-5 can be assembled and associated with the housing 10 at least at the upper edges of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com