Nonwoven fabric containing polyester complex fiber, preparation thereof and use as hydroscopic substance flow guiding layer

A non-woven fabric and composite fiber technology, applied in the field of non-woven fabrics, can solve the problems of tight fiber structure, hard hand feel, insufficient fluffy softness, etc., and achieve the effect of improving overall softness, fluffy thickness space, and ensuring dry performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

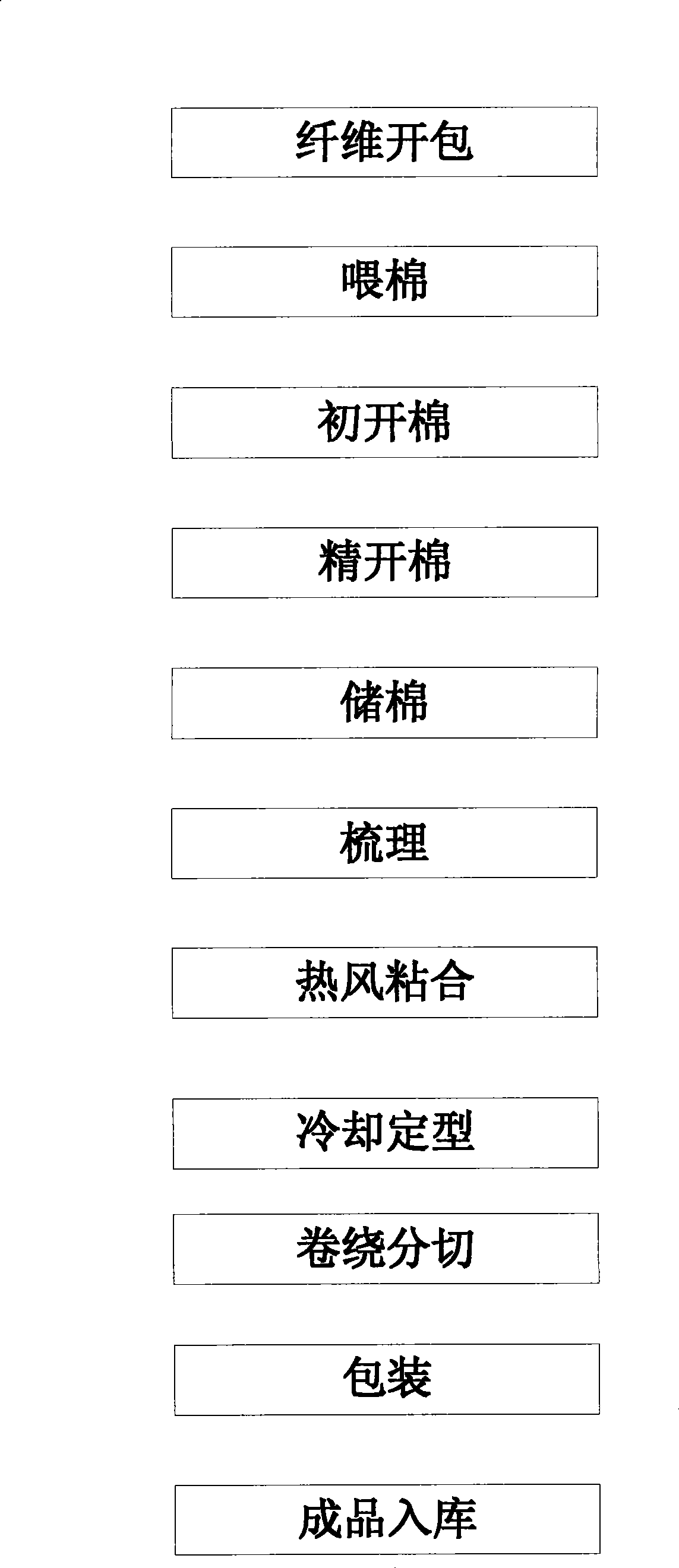

[0035] Example 1 Preparation of nonwovens containing PE / PP and PE / PET

[0036] Raw material formula:

[0037] formula PE / PP 50% PE / PET 50%

[0038] Preparation steps: unpack 50% PE / PP composite fiber material and 50% PE / PET composite fiber material raw material, feed it through the cotton feeding device, fully open and mix it, and card it into fiber by means of a carding device For the mesh layer, use the conveying belt to send the fiber mesh layer into the hot air device. The high temperature in the circulating hot air furnace of the hot air device and the high-speed up and down piercing wind speed will penetrate the fiber mesh layer and melt the fiber skin with a lower melting point. The fusion effect makes the fibers form a bridging bond, and then they are bonded together and then cooled and shaped. The cooling temperature is less than 60°C, and the semi-finished product is finished.

[0039] The finishing of non-woven fabrics is mainly to impr...

Embodiment 2

[0042] Example 2 Preparation of nonwoven fabric containing PE / PET

[0043] Raw material formula:

[0044] formula PE / PET 100%

[0045] Preparation steps: Unpack the raw material of 100% PE / PET composite fiber material and feed it through the cotton feeding device, after fully opening and mixing, comb it into a fiber web layer by means of a carding device, and use the conveyor belt to transport the fiber web The layers are fed into the hot air device, and the high temperature in the circulating hot air furnace of the hot air device and the high-speed up and down piercing wind speed penetrate the fiber web layer, melting the fiber skin with a lower melting point, and using this fusion to form a bridge between the fibers Combined, and bonded together, and then cooled and shaped, the cooling temperature is less than 60 ° C, and the semi-finished product is finished.

[0046] The finishing of non-woven fabrics is mainly to improve the performance of non-wove...

Embodiment 3

[0049] Example 3 Preparation of nonwovens containing PE / PP and PE / PET

[0050] formula PE / PP 70% PE / PET 30%

[0051] Preparation steps: After unpacking 70% PE / PP composite fiber material and 30% PE / PET composite fiber material, feed them through the cotton feeding device, fully open and mix them, and card them into fiber webs by means of a carding device Layer, using the conveyor belt to send the fiber web layer into the hot air device, the high temperature in the circulating hot air furnace of the hot air device and the high-speed up and down piercing wind speed will penetrate the fiber web layer and melt the fiber skin with a lower melting point. The fusion effect makes the fibers form a bridging bond, and they are bonded together, and then they are cooled and shaped. The cooling temperature is less than 60°C, and the semi-finished products are finished.

[0052] The finishing of non-woven fabrics is mainly to improve the performance of non-woven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com