Rare earth perovskite type fire-resistant material

A refractory material and perovskite-type technology, applied in the field of refractory materials, can solve the problems of unclear high-temperature mechanical properties, large thermal expansion coefficient, poor thermal shock resistance, etc., and achieve optimized microstructure and stable high-temperature chemical properties , Improve the effect of thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: Comprising the following components by weight percentage, LaCrO 3 75%, ZrO 2 25%.

[0018] LaCrO 3 The atomic structure is perovskite type.

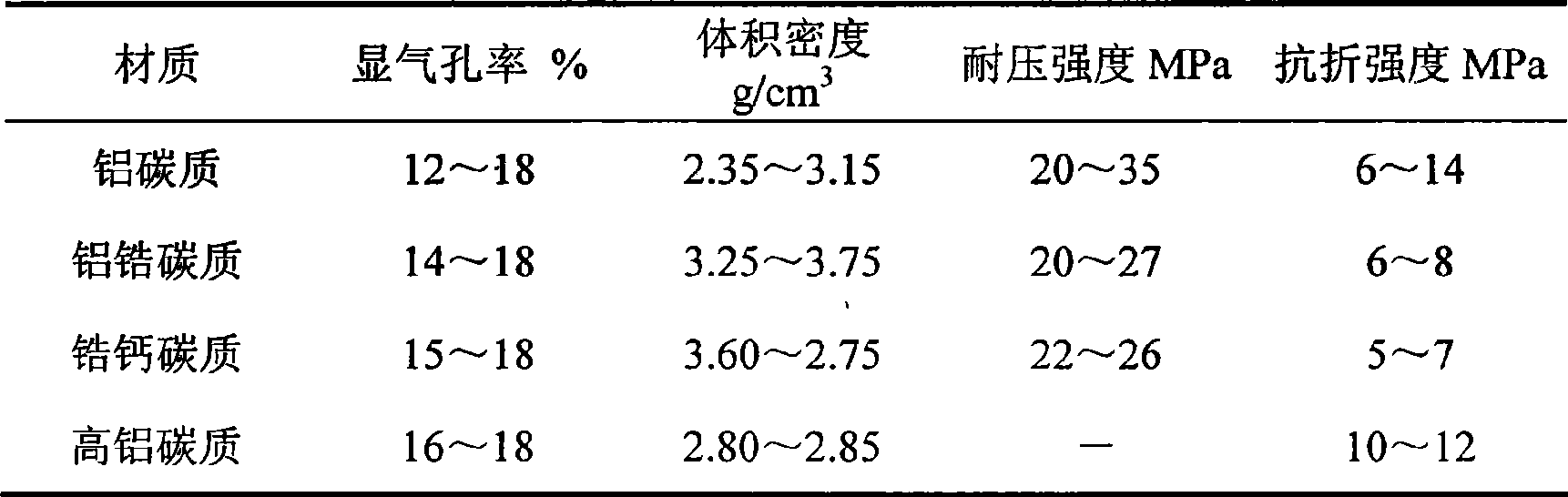

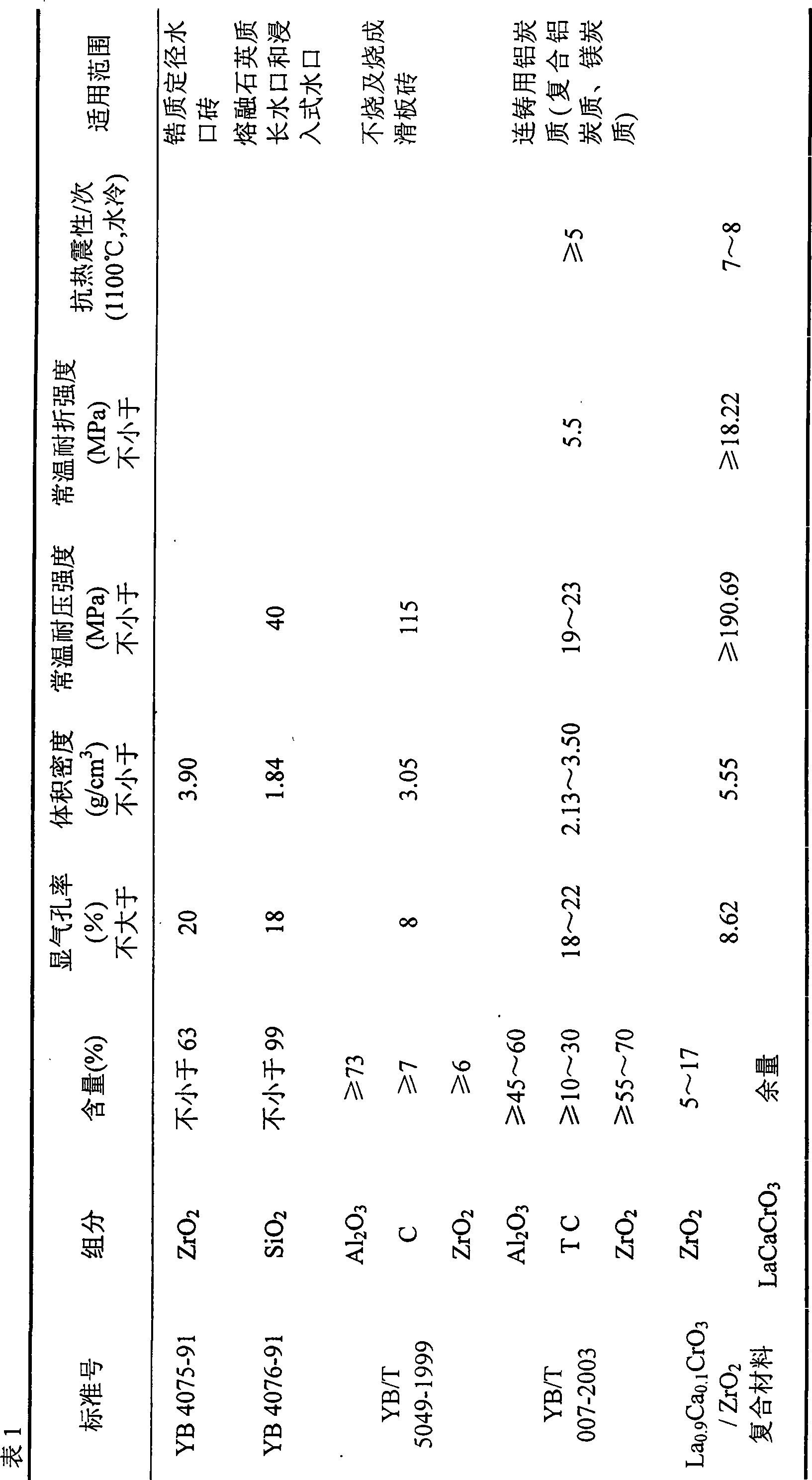

[0019] In the present invention, the high temperature oxide ZrO 2 As the second phase, it is added to the rare earth oxide lanthanum chromate matrix at a certain mass percentage to prepare a composite material, and the performance of the refractory material is greatly improved by adding and sintering. The specific indicators are shown in Table 1.

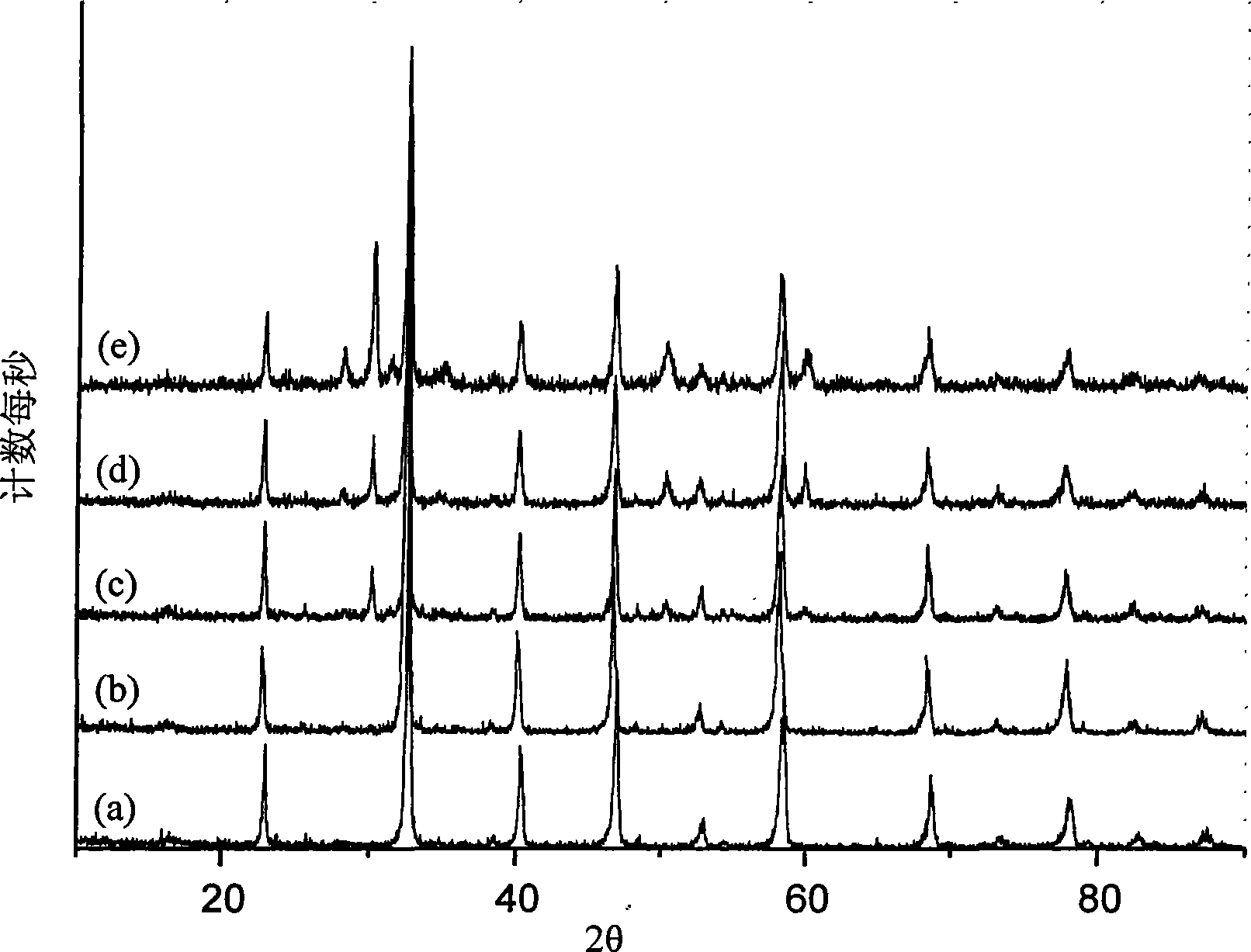

[0020] The present invention detects ZrO through X-ray diffraction after high temperature sintering 2 There is no reaction with the matrix structure of lanthanum chromate, no new phase is formed, and the La 1-x Ca x CrO 3 structural composition. Such as figure 1 shown.

Embodiment 2

[0021] Embodiment 2: Embodiment 1: Comprising the composition of following percentage by weight, LaCrO 3 85%, ZrO 2 15%.

[0022] LaCrO 3 The atomic structure is perovskite type.

[0023] In the present invention, the high temperature oxide ZrO 2 As the second phase, it is added to the rare earth oxide lanthanum chromate matrix at a certain mass percentage to prepare a composite material, and the performance of the refractory material is greatly improved by adding and sintering. The specific indicators are shown in Table 1.

[0024] The present invention detects ZrO through X-ray diffraction after high temperature sintering 2 There is no reaction with the matrix structure of lanthanum chromate, no new phase is formed, and the La 1-x Ca x CrO 3 structural composition. Such as figure 1 shown.

Embodiment 3

[0025] Embodiment 3: Comprising the following components by weight percentage, LaCrO 3 90%, ZrO 2 10%.

[0026] LaCrO 3 The atomic structure is perovskite type.

[0027] In the present invention, the high temperature oxide ZrO 2 As the second phase, it is added to the rare earth oxide lanthanum chromate matrix at a certain mass percentage to prepare a composite material, and the performance of the refractory material is greatly improved by adding and sintering. The specific indicators are shown in Table 1.

[0028] The present invention detects ZrO through X-ray diffraction after high temperature sintering 2 There is no reaction with the matrix structure of lanthanum chromate, no new phase is formed, and the La 1-x Ca x CrO 3 structural composition. Such as figure 1 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com