Use of fly ash synthesized channel joint impervious material for preparing highway asphalt mixture

A technology of asphalt mixture and anti-seepage material, which is applied in the field of known materials, can solve the problems of dry and hard cracking durability of the road surface, hinder the health of operators, reduce the service life and other problems, achieve the improvement of fatigue life, good effect, and reduce Economic cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of medium-sized AC-20 densely graded modified asphalt mixture

[0035] Mineral material: All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004).

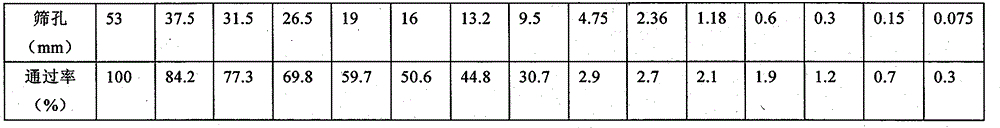

[0036] The gradation of AC-20 ore is:

[0037]

[0038] Cementing material: fly ash synthetic channel joint anti-seepage material, A and B two-component, A: B (weight ratio) = 1: 1, wherein, the formula of A and B components should meet the requirements of patent ZL200310118992.X. Fly ash synthetic channel joint anti-seepage material in the cement: No. 70 road petroleum asphalt = 40%: 60%.

[0039] Oil-stone ratio: 5.0%.

[0040] Preparation steps: Prepare the road mixture according to the preparation steps described in the summary of the invention, and make Marshall test pieces and splits according to the T0702-2000 regulations and T0703-1993 regulations in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engin...

Embodiment 2

[0051] Embodiment 2: fine-grained type SMA-13 asphalt horseshoe fat macadam mixture

[0052] Mineral material: All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004).

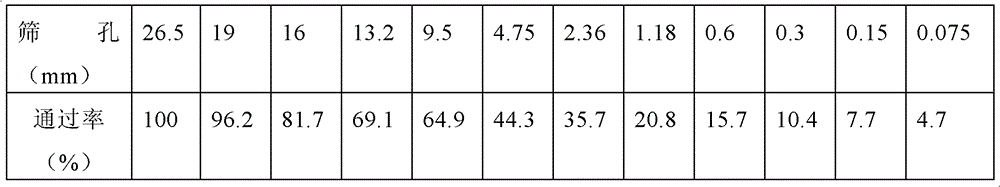

[0053] The fine-grained SMA-13 mineral material gradation is:

[0054]

[0055] Cementing material: fly ash synthetic channel joint anti-seepage material, which is two-component A and B, A:B (weight ratio) = 1:2, wherein, the formula of A and B components should meet the requirements of patent ZL200310118992.X. Fly ash synthetic channel joint anti-seepage material in cement: No. 70 road petroleum asphalt = 50%: 50%.

[0056] Oil-stone ratio: 5.3%.

[0057]Preparation steps: Prepare the road mixture according to the preparation steps described in the summary of the invention, and make Marshall test pieces and splits according to the T0702-2000 regulations and T0703-1993 regulations in the "Test Regulations for Asphalt and Asphalt Mix...

Embodiment 3

[0068] Example 3: Densely graded asphalt stabilized macadam mixture

[0069] Mineral material: All properties meet the requirements of "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004).

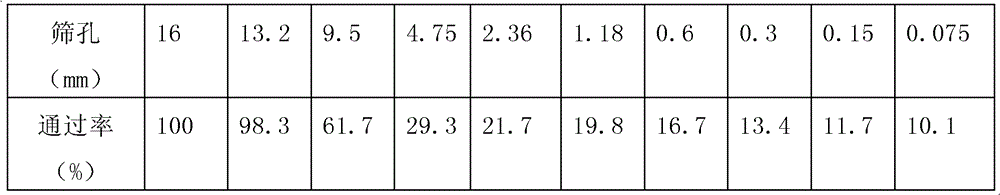

[0070] Coarse-grained ATB-25 ore gradation is:

[0071]

[0072] Cementing material: fly ash synthetic channel joint anti-seepage material, which is two-component A and B, A:B (weight ratio) = 1:3, wherein, the formula of A and B components should meet the requirements of patent ZL200310118992.X. Fly ash synthetic channel joint anti-seepage material in cement: No. 70 road petroleum asphalt = 60%: 40%.

[0073] Oil-stone ratio: 4.9%.

[0074] Preparation steps: Prepare the asphalt mixture according to the preparation steps described in the summary of the invention, and make the Marshall test piece and split Crack, rutting test, linear shrinkage coefficient test piece. According to the T0709-2000, T0719-1993, T0716-1993, T0720-1993 regulations, the Mar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stability | aaaaa | aaaaa |

| residual stability | aaaaa | aaaaa |

| residual stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com