Vacuum cultivation system

A vacuum and cultivation room technology, applied in the field of plant cultivation, can solve the problems of changing plant productivity and difficult realization, and achieve the effect of reducing costs and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

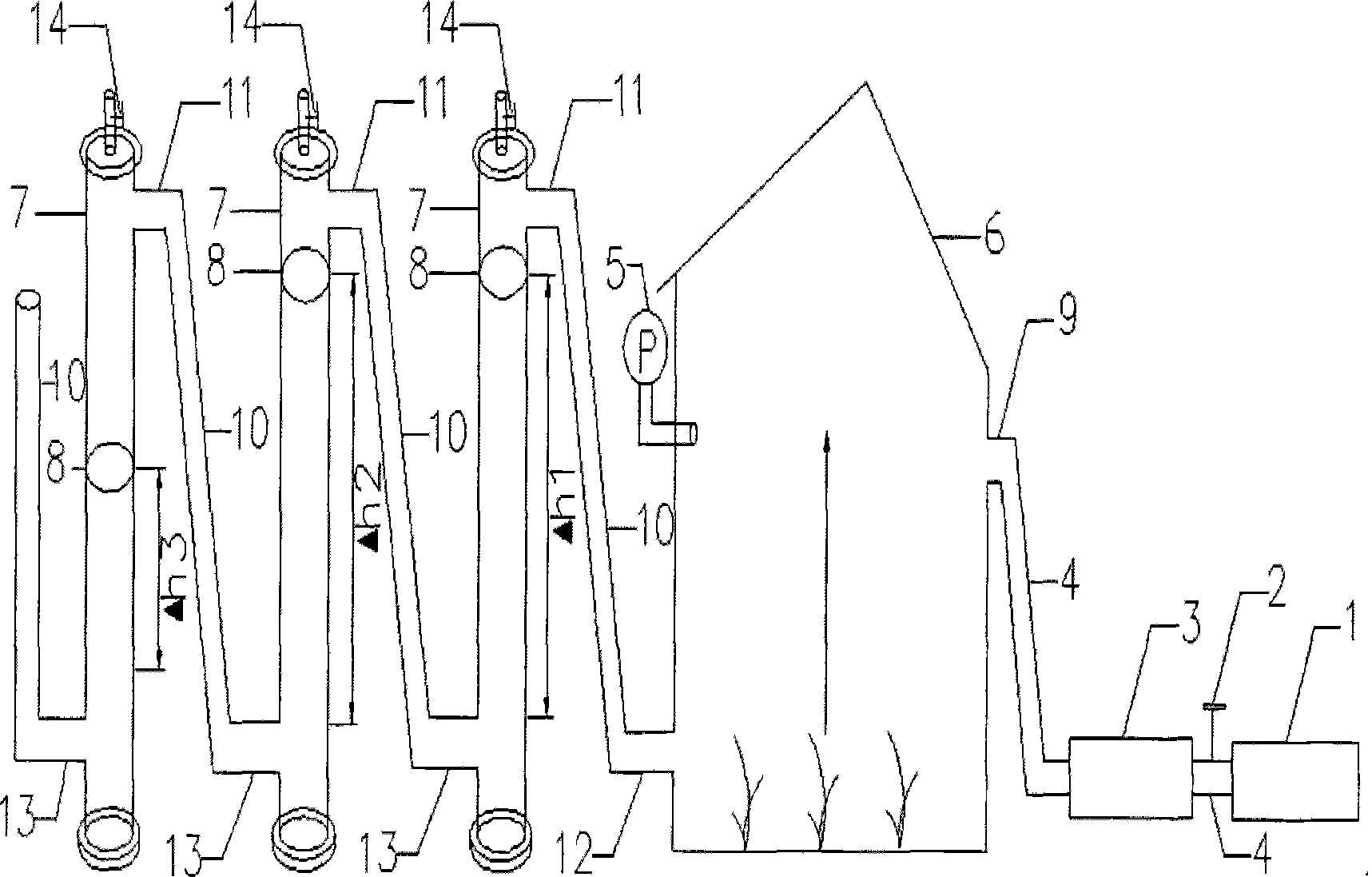

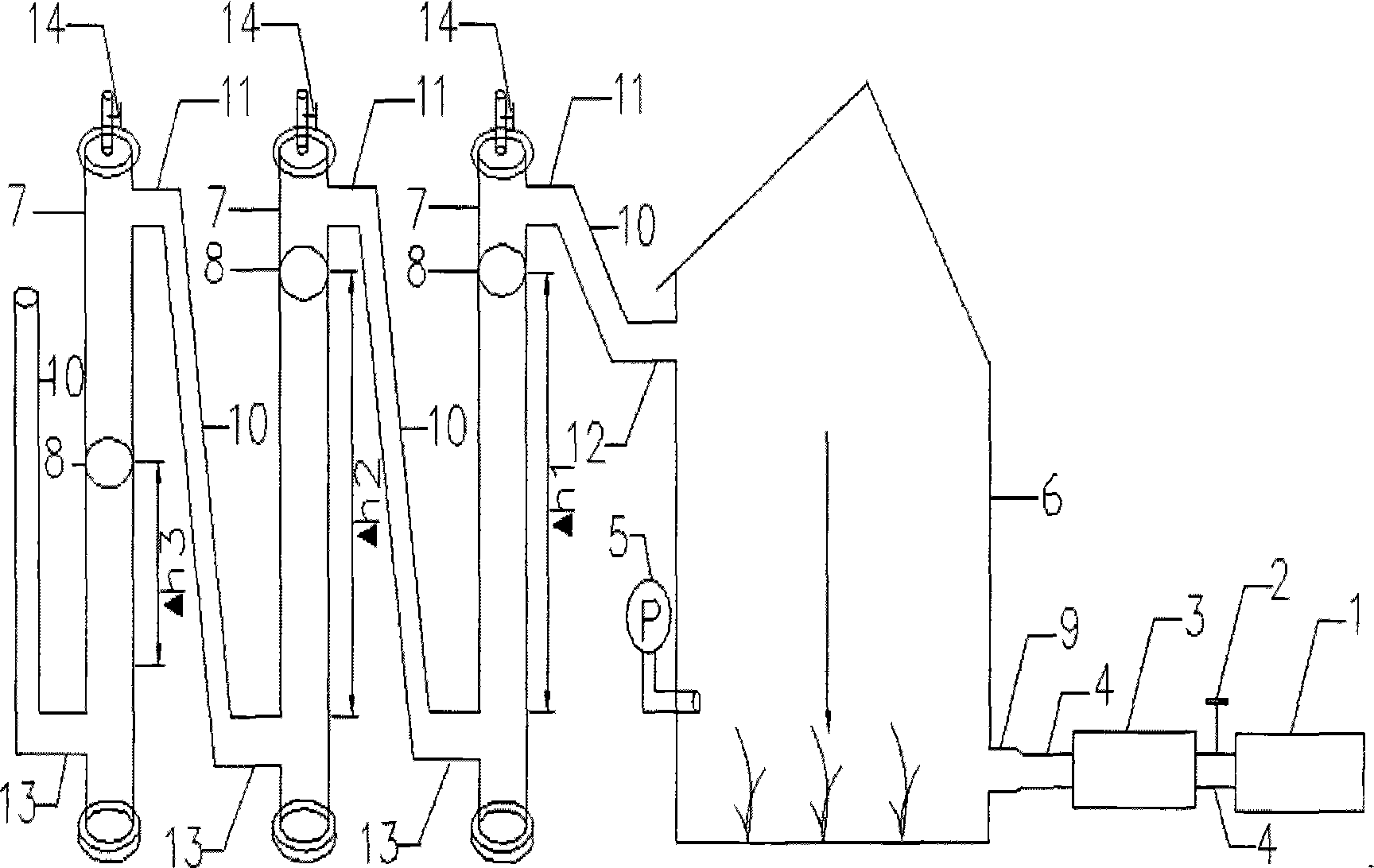

[0031] refer to figure 1 with figure 2 Shown, the structural representation of the vacuum cultivation system embodiment of the present invention; Wherein, figure 1 It is a structural schematic diagram in which the airflow direction inside the cultivation chamber 6 is upward, figure 2 It is a structural schematic diagram showing that the airflow direction inside the cultivation chamber 6 is downward; the vacuum cultivation system mainly includes: an airtight cultivation chamber 6, a mechanical pump 1, an air valve 2, a gas flow controller 3, three pressure control pipes 7, four One air guide tube 10, two outlet air guide tubes 4, valve 14.

[0032] The cultivation chamber 6 in the present embodiment is a greenhouse with a seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com