Controllable vacuumizing pipeline device for forming mold for transparent part of aircraft

A technology for forming molds and vacuum tubes, which is applied in the field of controllable vacuum pipeline devices for forming molds for transparent parts of aircraft, and can solve problems such as uncontrollable vacuum degree, easy wrinkles in glass forming, and cloth lines on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

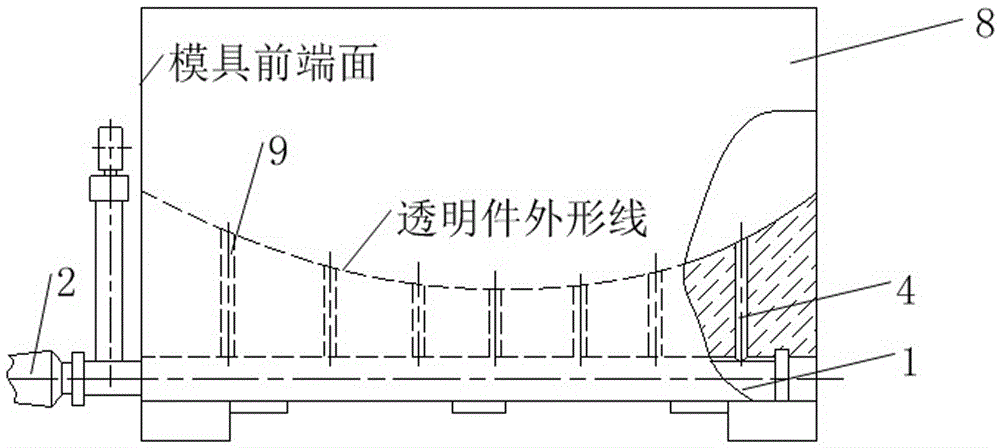

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

[0025] A controllable vacuum pumping pipeline device for a forming mold of an aircraft transparent part, which includes a vacuum pipeline and a vacuum pumping device;

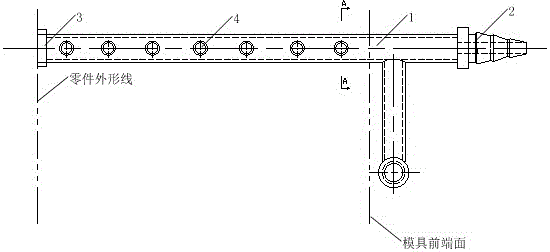

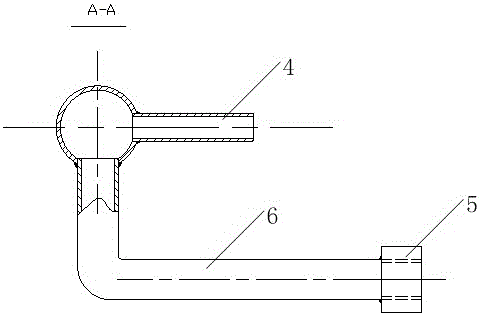

[0026] The exhaust pipe 1, branch pipe 4 and elbow 6 on the vacuum pipeline are integrated by welding, the elbow 6 is welded on the front end of the exhaust pipe 1, and the other end of the elbow 6 is welded with a vacuum pressure gauge connector 5;

[0027] A plurality of branch pipes 4 are welded in the radial direction of the exhaust pipe 1;

[0028] The metal blocking cover 3 is welded on the end of the exhaust pipe 1, the first pipe joint 2 is welded on the other end of the exhaust pipe 1, and the end surface of the metal blocking cover 3 coincides with the contour line of the parts on the mold;

[0029] The vacuum pipeline is installed in the transparent part forming mold 8, the suction pipe 1 is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com