Laser processing method

A laser processing method and laser processing technology, which are applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems that affect cutting quality, cannot be separated, excessive ablation of cutting edges, etc., achieve good processing effects, and avoid excessive cutting. Ablation, the effect of improving the degree of exclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

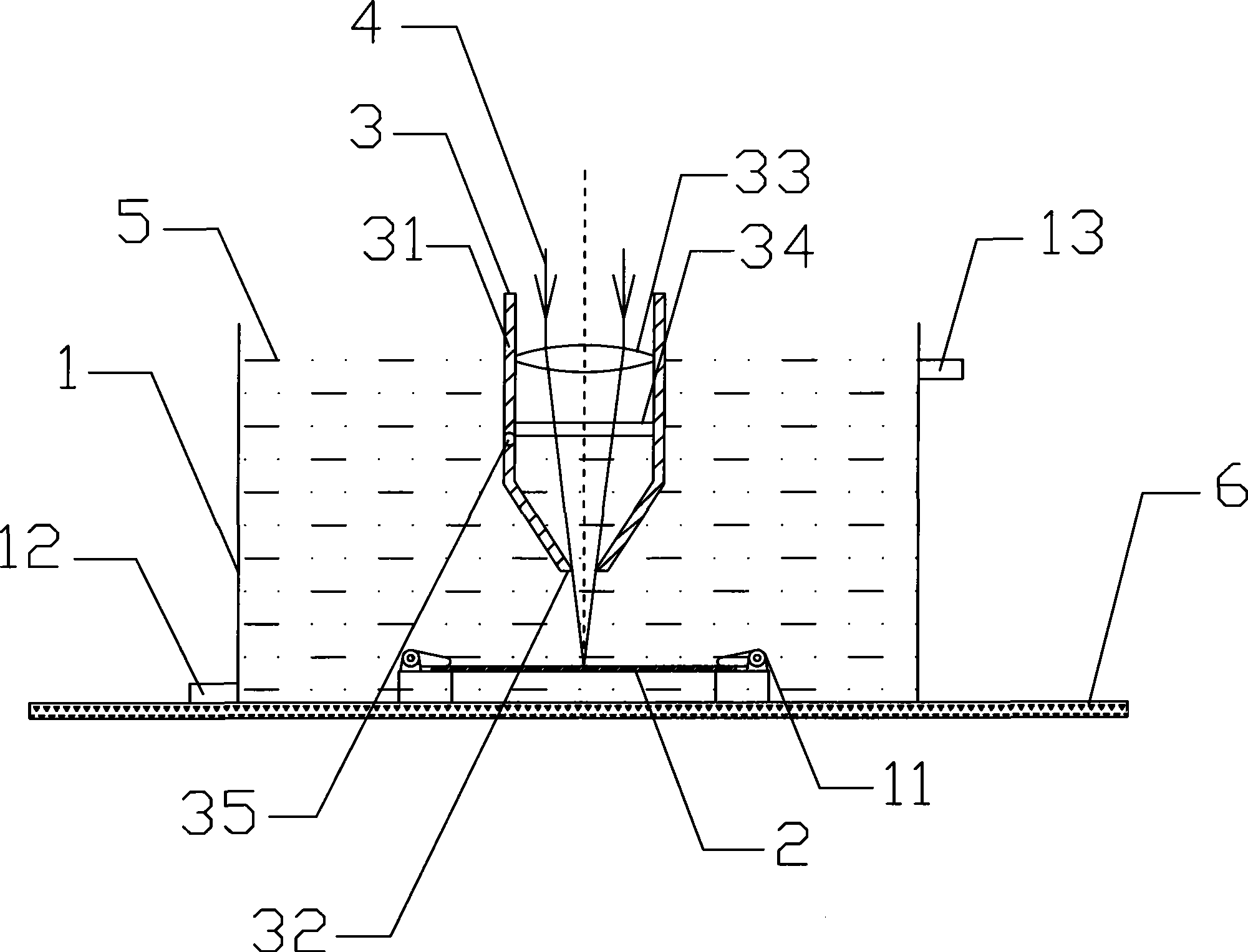

[0017] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

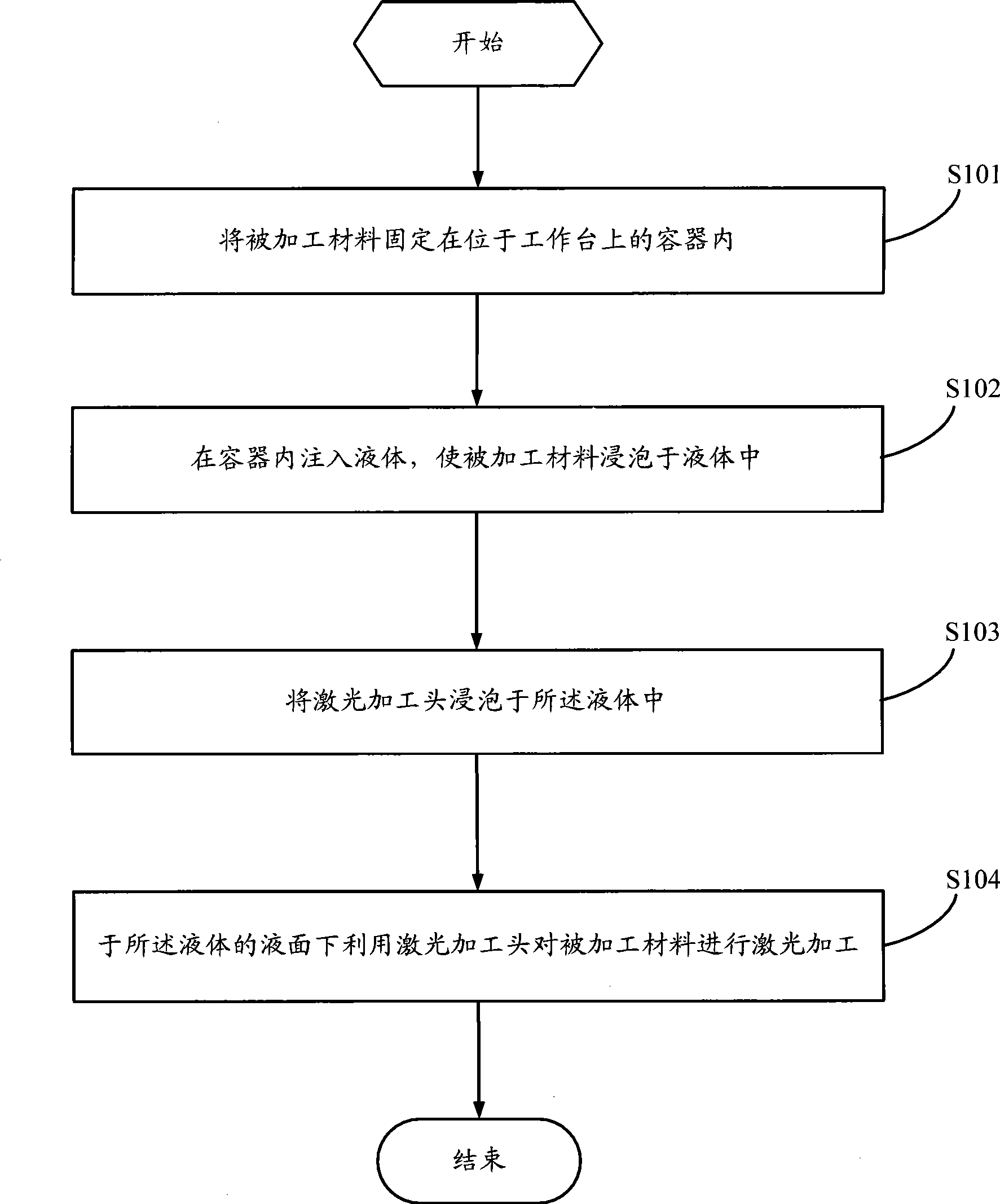

[0018] Please combine figure 1 with figure 2 As shown, the laser processing method of Embodiment 1 of the present invention includes the following steps:

[0019] Step S101, fixing the material to be processed in the container on the workbench.

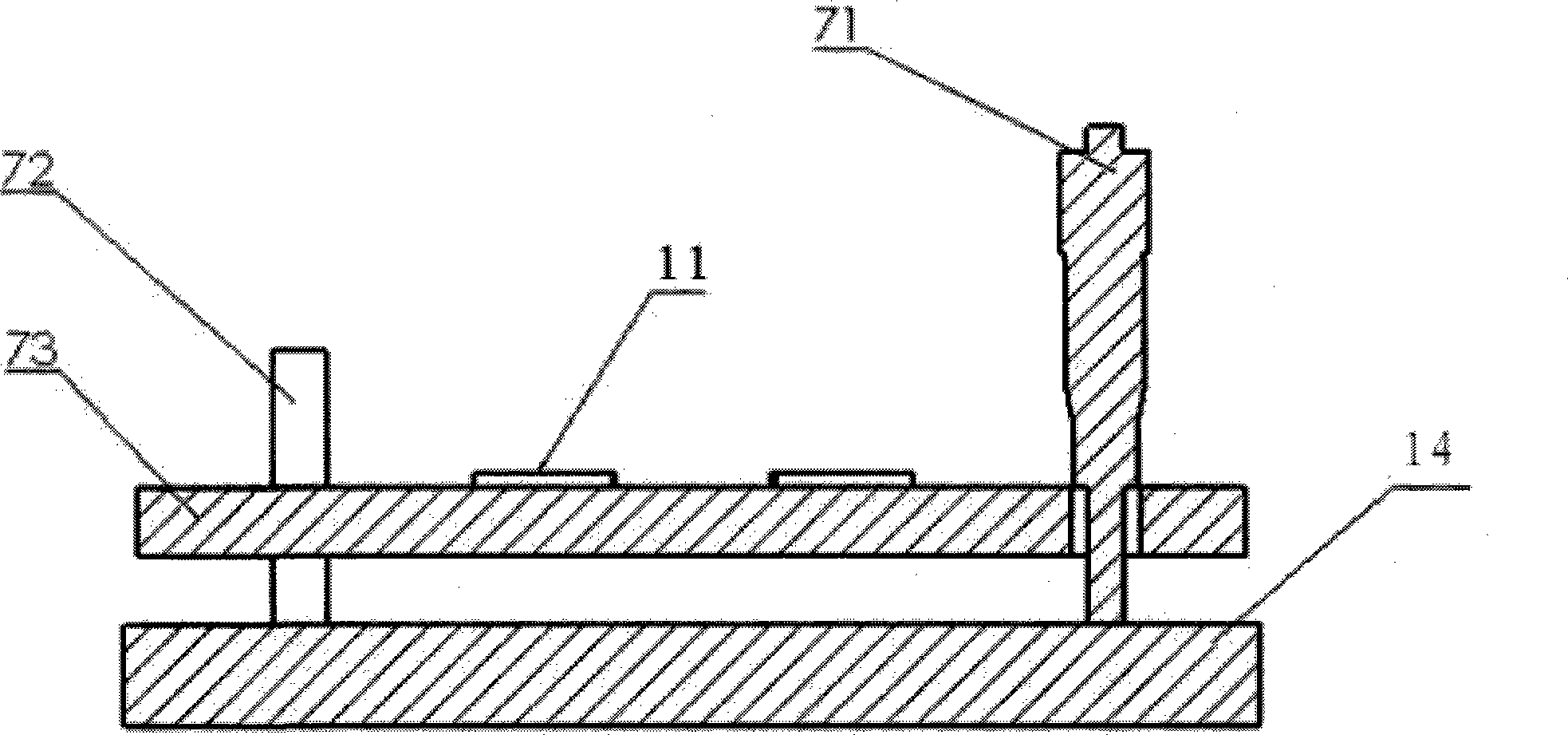

[0020] The container 1 being fixed on the workbench 6 is a square container with an upper opening, a clamp 11 is installed at its bottom, a water outlet 12 is provided on one side, and a water inlet 13 is provided on the opposite side. When fixing the processed material 2 , it is only necessary to put the processed material 2 from the opening above the container 1 and fix the processed material 2 with the clamp 11 .

[0021] The container described in the embodiment of the present invention can be made of light-transmitting material, so that the operator can observe the laser processing process during the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com