Preparation method of thermoplastic substrate ultra-hydrophobic film

A thermoplastic film, super-hydrophobic technology, which is applied to devices for coating liquids on surfaces, special surfaces, coatings, etc., can solve the problem of inability to achieve large-scale applications of super-hydrophobic surfaces, low mechanical strength of super-hydrophobic surfaces, and super-hydrophobic structures. The problem of high cost, to achieve the effect of easy promotion, excellent mechanical properties and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the superhydrophobic film of the thermoplastic substrate of the present embodiment, comprises the following steps:

[0030] a. Heat the thermoplastic film substrate to make it melt and soften. In this embodiment, the thermoplastic film substrate 1 is a polyethylene film;

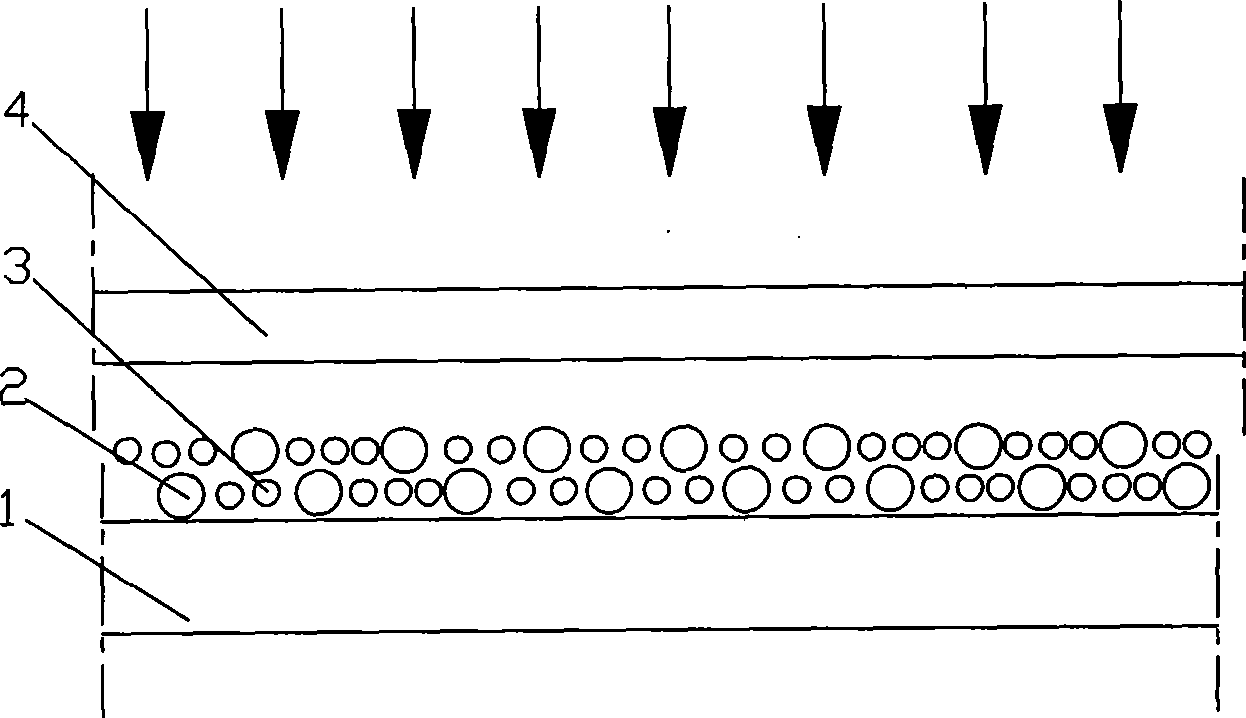

[0031] b. Sprinkle the mixed powder of micron-sized powder 2 and nano-sized powder 3 with low surface energy evenly on the surface of polyethylene film. In this embodiment, the micron-sized powder and nano-sized powder are perfluoroethylene propylene micropowder , the particle size of the mixed powder of micron-sized powder and nano-sized powder is 60nm-100μm; cover the micron-sized powder and nano-sized powder with a flat plate 4 and apply a force perpendicular to the surface of the flat plate to make the micron-sized powder and nano-sized powder The powder particles are embedded in the surface of the melted and softened polyethylene film substrate and form micron-scale prot...

Embodiment 2

[0035] The preparation method of the superhydrophobic film of the thermoplastic substrate of the present embodiment, comprises the following steps:

[0036] a. Heat the thermoplastic film substrate 1 to make it melt and soften. In this embodiment, the thermoplastic film substrate is a polyvinyl chloride film, which has good strength and is suitable for being made into an adhesive tape form and is easy to use;

[0037] b. Sprinkle the mixed powder of micron-sized powder 2 and nano-sized powder 3 with low surface energy evenly on the surface of the polyvinyl chloride film. In this embodiment, the micron-sized powder and nano-sized powder are polytetrafluoroethylene The particle size of the mixed powder of micropowder, micron-sized powder and nano-sized powder is 400nm-30μm; cover the micron-sized powder and nano-sized powder with a plate 4 and apply a force perpendicular to the surface of the plate to make the micron-sized powder and nano-sized powder Nano-scale powder particles...

Embodiment 3

[0041] The preparation method of the superhydrophobic film of the thermoplastic substrate of the present embodiment, comprises the following steps:

[0042] a. Heat the thermoplastic film substrate 1 to melt and soften it. In this embodiment, the thermoplastic film substrate is a polypropylene film;

[0043] b. Sprinkle the mixed powder of micron-sized powder 2 and nano-sized powder 3 with low surface energy evenly on the surface of the polypropylene film. In this embodiment, the micron-sized powder and nano-sized powder are perfluoroethylene propylene micropowder Mixed with polytetrafluoroethylene micropowder, micron-sized powder and nano-sized powder, the particle size of the mixed powder is 400nm-30μm; cover the micron-sized powder and nano-sized powder with a flat plate 4 and apply a force perpendicular to the surface of the flat plate, Embed micron-scale powder and nano-scale powder into the surface of melted and softened polyvinyl chloride film to form micron-scale protrus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com