High solarization light fastness extra white fabric and manufacturing method thereof

A fabric and fastness technology, applied in the field of white fabrics, can solve the problems of incorrect color and easy yellowing of fabrics, and achieve the effect of reducing whiteness and good wet fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

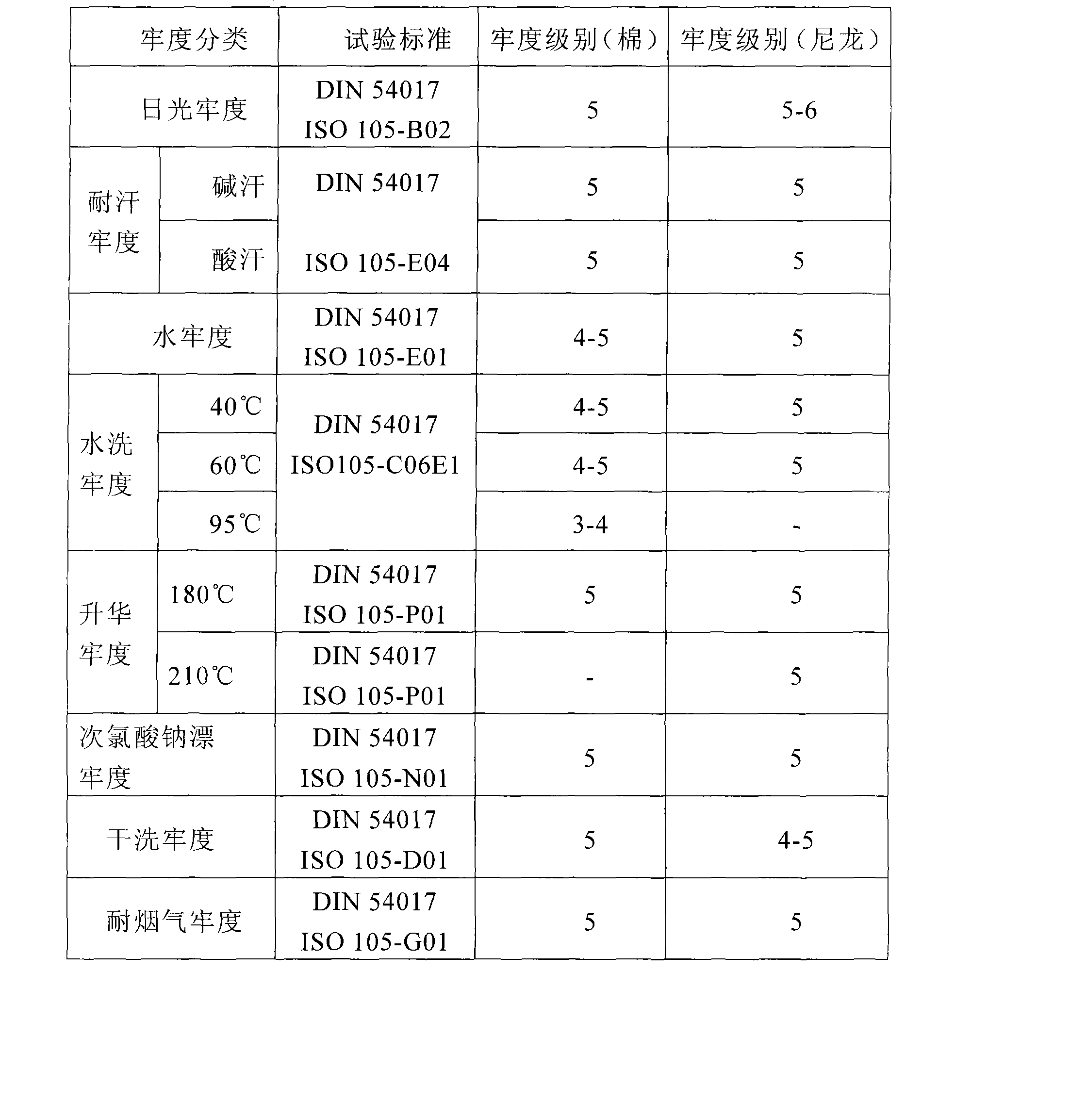

[0020] The invention discloses an ultra-white fabric with high light fastness, which includes a fabric to be treated, and the ultra-white fabric with high light fastness is obtained through fluorescent whitening agent treatment and reduction bleaching during the bleaching process. The fluorescent whitening agent is mainly composed of bistriazinyl stilbene and its derivatives.

[0021] Said a kind of extra-white fabric with high light fastness, said fluorescent whitening agent mainly includes: bistriazine-based stilbene derivatives, stilbene triazole derivatives, benzoxazole derivatives one or several.

[0022] The preparation method of described a kind of high light fastness special white fabric, it comprises the following steps:

[0023] Put the fabric to be treated in the treatment bath, and add pretreatment agent BFN-07 (fatty alcohol polyoxyethylene ether mixture), hydrogen peroxide stabilizer PSL (polyacrylate and organic phosphate mixture), NaOH (sodium hydroxide ), H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com