Method for preparing multi-wall carbon nano-tube composite material

A multi-walled carbon nanotube and carbon nanotube technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of carbon nanotube application limitation, insolubility, lack of surface functional groups, etc. Effects of reversible changes, improved compatibility, facile preparation process and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 100mL single-neck round-bottom flask, 2.0g of multi-walled carbon nanotubes prepared by chemical vapor deposition (CVD) were dispersed in 60ml of concentrated nitric acid / concentrated sulfuric acid mixed acid solution, at 35°C with 40KHz Power sonication for 8h. Suction filtration with a Φ0.2 μm polytetrafluoroethylene microporous membrane, repeated washing with deionized water until the filtrate becomes neutral, and vacuum drying at 40°C for 72 hours to obtain surface carboxylated carbon nanotubes. After vacuum drying, 0.10 g of surface carboxylated carbon nanotubes and 0.8 g of lithium aluminum hydride were ultrasonically dispersed in toluene, stirred and reacted for 72 hours at 20-40° C. to obtain about 0.08 g of surface hydroxylated carbon nanotubes; 0.08 g surface hydroxylated carbon nanotubes and 0.03 g trimethoxy-p-benzylchlorophenylsilane coupling agent, ultrasonically dispersed in toluene. Stir and reflux at 40-80° C. for 24 hours to obtain about 0.09 g o...

Embodiment 2

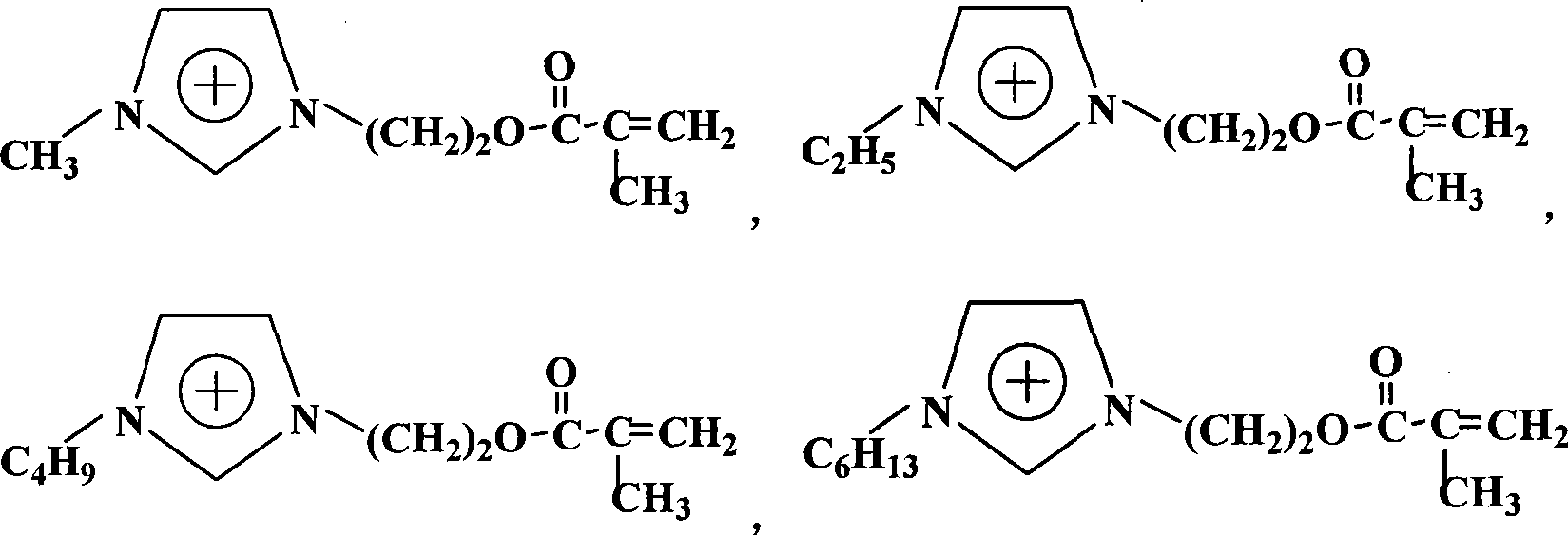

[0028] The same method as in Example 1 was used to obtain carbon nanotubes with surfaces rich in benzyl chloride.

[0029] In a 25mL three-neck round bottom flask, add 0.08g of carbon nanotubes whose surface is rich in benzyl chloride, about 0.05g of cuprous chloride, and 0.1g of pentamethyl-diethyltriamine, and ultrasonically disperse them in methanol After the degassing treatment, the ionic liquid monomer 1-butyl-3-(2-methacryloyloxyethyl)imidazole containing methacrylate functional group was gradually added under nitrogen protection, and the reaction was stopped after 72 hours. Add a large amount of tetrahydrofuran to the reaction system, filter with suction, and wash repeatedly 3 times to ensure that unreacted monomers and catalysts and some homopolymers generated in the reaction are completely removed, and the product is vacuum-dried overnight to obtain polymethacrylate-type polymers. Water-soluble carbon nanotubes grafted by ionic liquid, wherein the anions of the polyel...

Embodiment 3

[0032] The carbon nanotube / polyionic liquid composite material was obtained by the same method as in Example 2.

[0033] The carbon nanotube / polyionic liquid composite material is first subjected to anion exchange to obtain a composite material in which the hydrophobic anion is hexafluorophosphate, and the product is ultrasonically dispersed in dichloromethane, and a concentration of 1.0mol / L is added to it. The sodium bromide aqueous solution was shaken, and the carbon nanotubes were transferred from the organic phase to the aqueous phase, indicating that the hydrophobic composite material was transformed into a hydrophilic substance. Adding a sodium trifluoroacetate aqueous solution with a concentration of 1.0 mol / L to the aqueous phase, the composite material was transferred into the organic phase again, indicating that the composite material could be converted into a hydrophobic substance again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com