Laser cutting control method

A control method, laser cutting technology, applied in the direction of digital control, laser welding equipment, electrical program control, etc., can solve the problem that the machine tool cannot run continuously, achieve the effect of improving cutting efficiency, reducing alarm frequency, and avoiding alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the technical field of the present invention, without departing from the concept of the present invention, some simple deduction or replacement can be made, which should be regarded as belonging to the protection scope of the present invention.

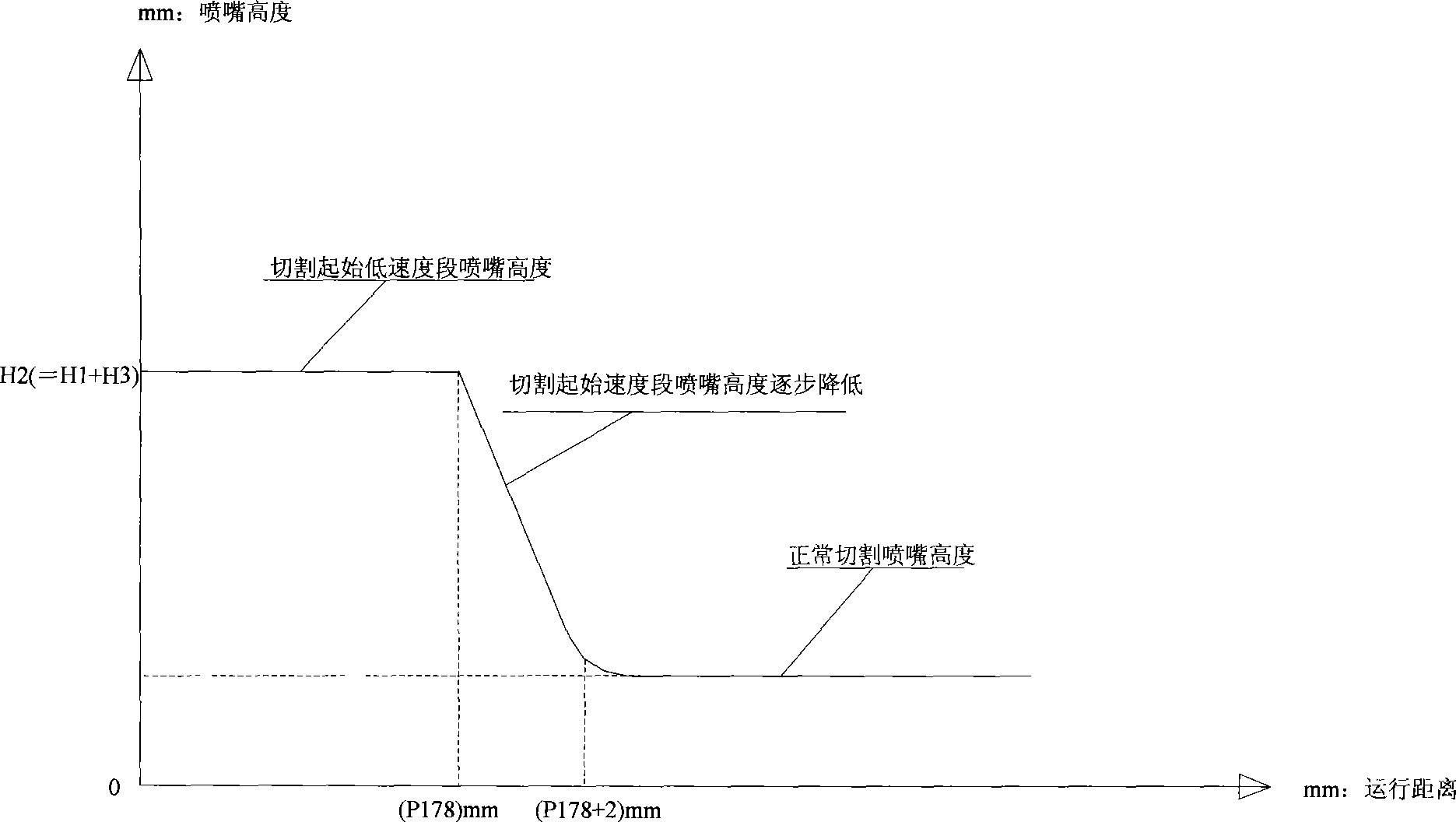

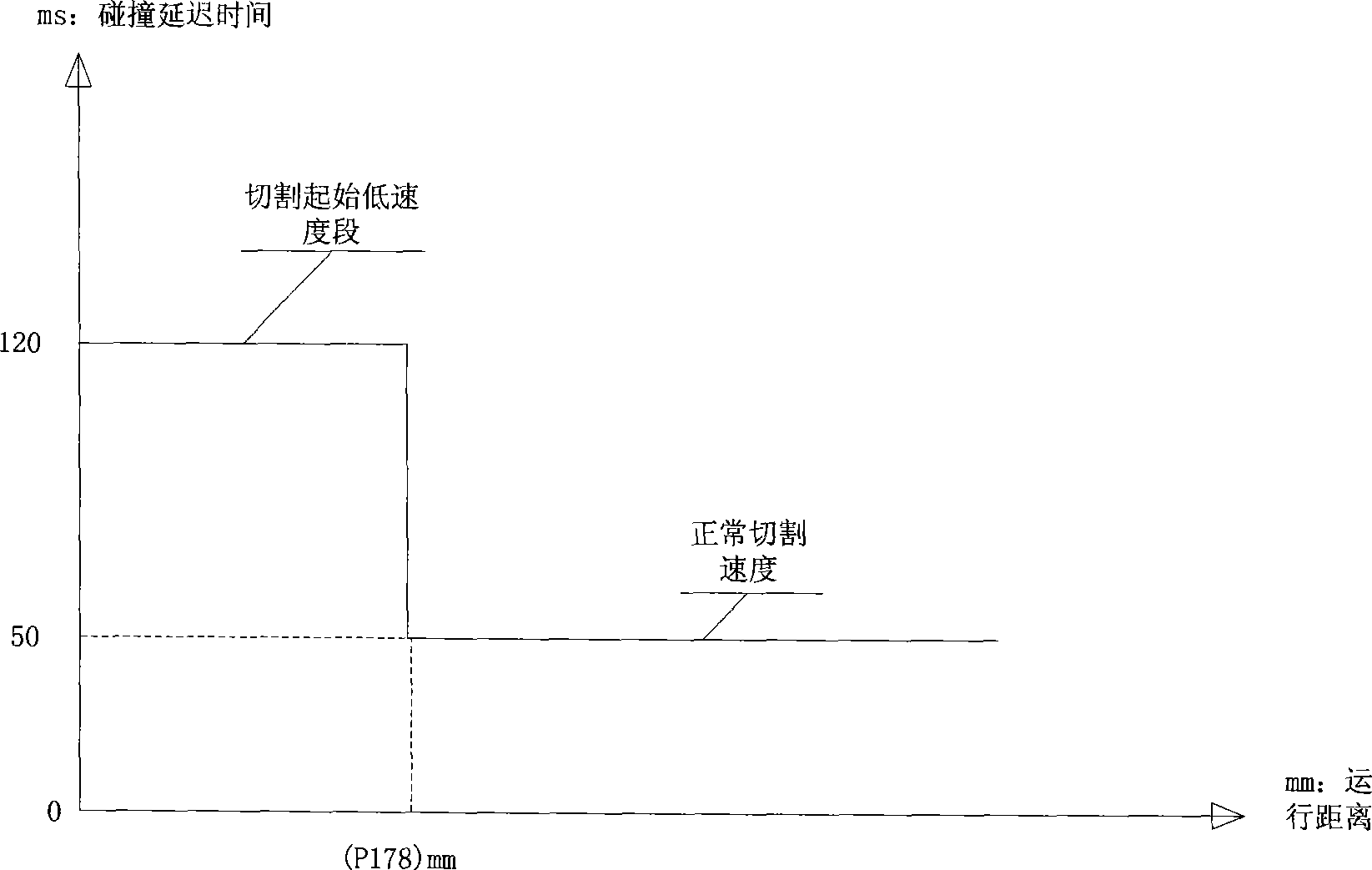

[0013] The laser cutting control method of the present invention is aimed at laser cutting machine tools, which will produce hole slag and whiskers of hole slag after the thick plate (above 3MM) stainless steel plate is perforated, which is easy to touch the laser cutting head height sensor, causing the sensor to collide and protect the alarm. Interrupt the cutting process. In order to make the cutting go on normally, it is necessary to eliminate some ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com