Vegetable washer

A vegetable washing machine and inner barrel technology, which is applied to household appliances, food processing, food science, etc., can solve the problems of wasting water, trouble, time-consuming and laborious, and save time, improve washing efficiency, and adapt to a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

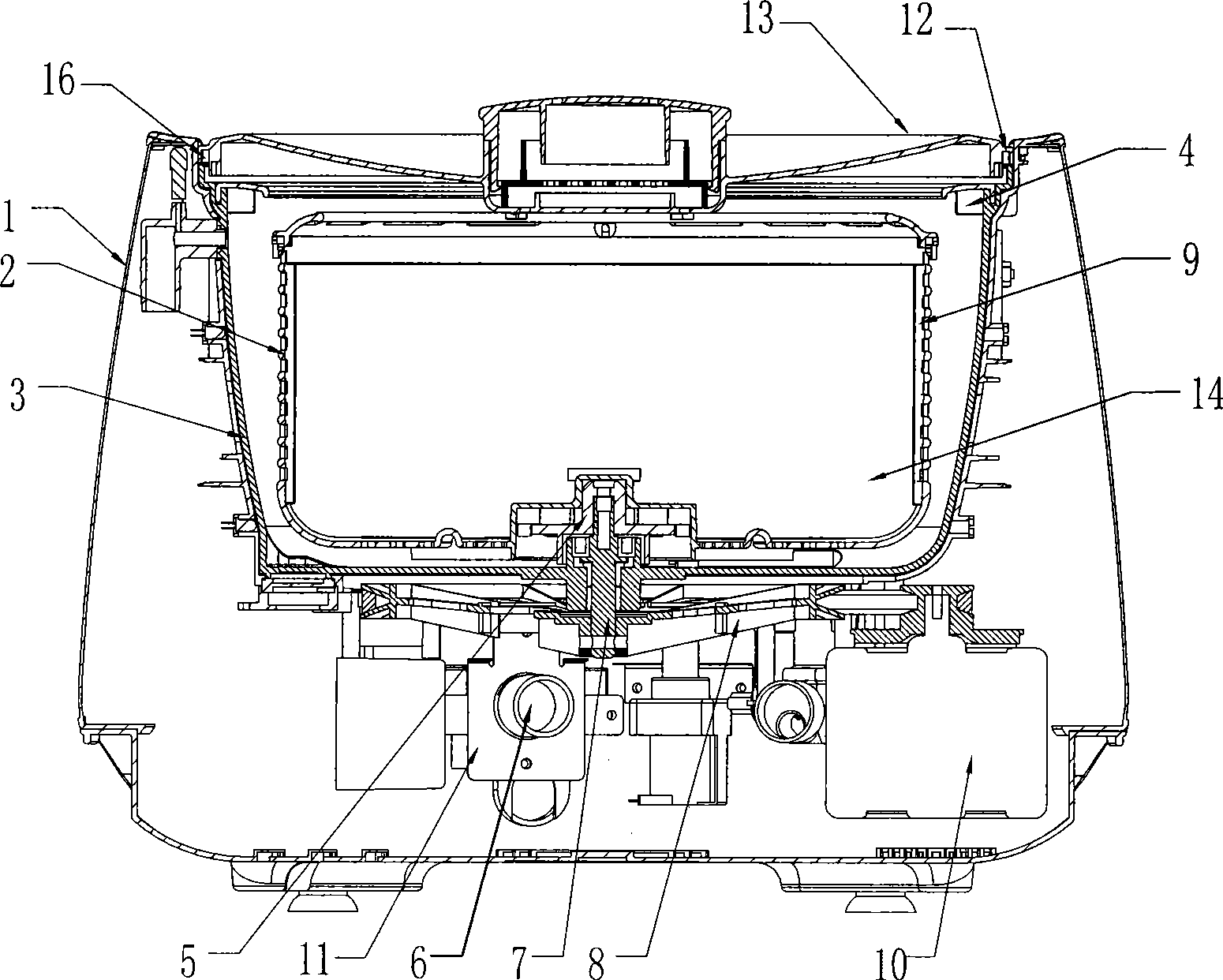

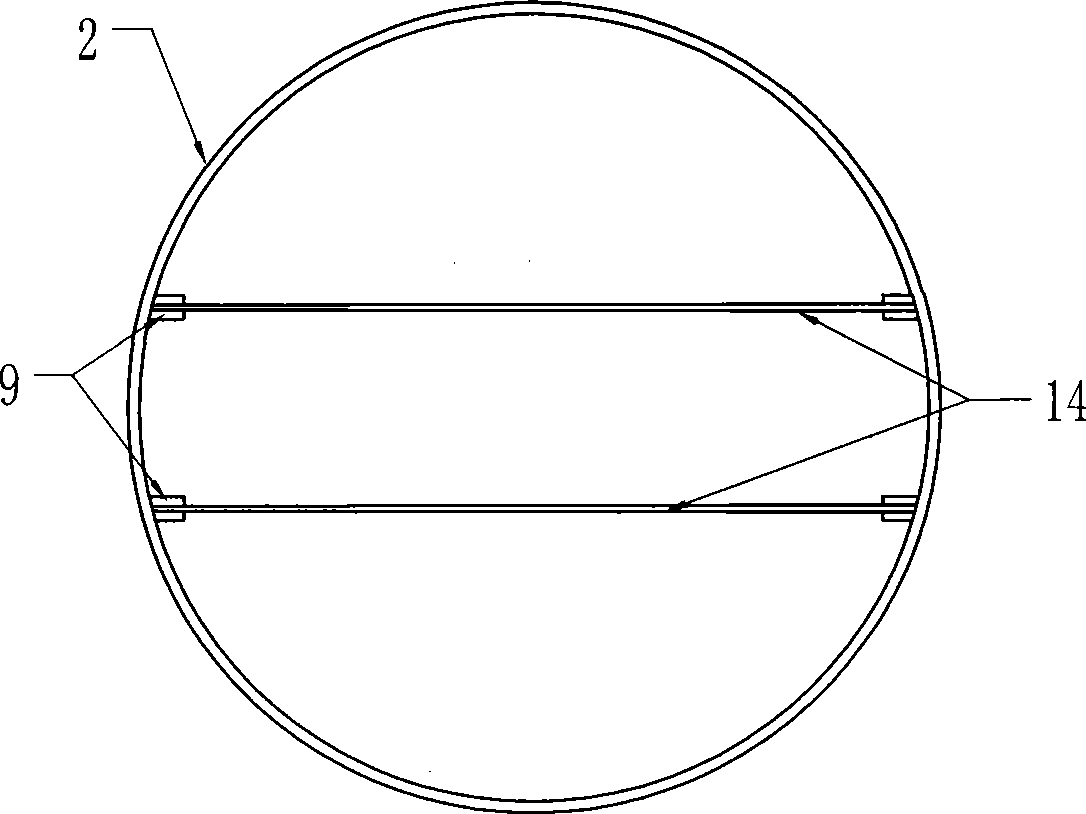

[0020] Embodiment 1, as figure 1 As shown, a vegetable washing machine includes a housing 1, a driving device 10 located in the housing 1, an outer tub 3 and an inner tub 2, wherein the inner tub 2 is concentrically set in the outer tub 3, and the inner tub 2 is provided with a detachable A partition 14, the partition 14 is vertically arranged in the inner barrel 2, a vertical guide groove 9 is provided on the inner side wall of the inner barrel 2, the side of the partition 14 is inserted into the guide groove 9 to fix the partition 14, and the inner barrel 2 separated into left and right parts.

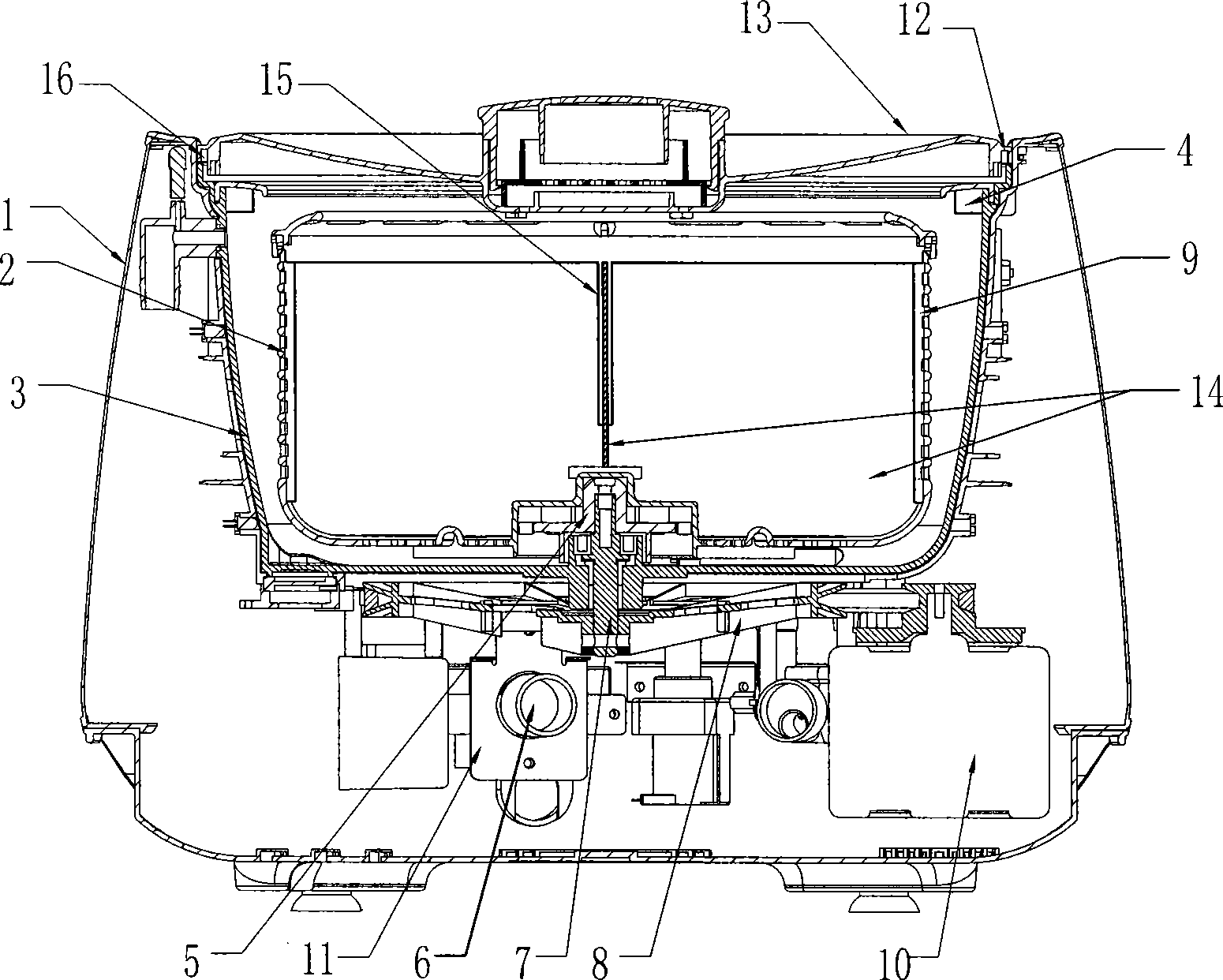

[0021] Such as figure 2 As shown, two partitions 14 intersecting each other are inserted in the inner barrel 2, and the partition 14 has a vertical connection groove 15 from the center to the outer edge, and the two partitions 14 are inserted and fixed together through the connection groove 15. , the inner barrel 2 is divided into four different spaces.

[0022] Such as image 3...

Embodiment 2

[0026] Embodiment 2, as Figure 5 As shown, the partition 14 is horizontally arranged in the inner barrel 2, and separates the inner barrel 2 up and down. Two horizontal convex edges 17, 18 protruding inward are arranged at intervals on the side wall of the inner barrel 2, and the two partitions 14 are respectively Placed on the convex edges 17 and 18, the width of the upper convex edge 17 is smaller than the width of the lower convex edge 18, and the diameter of the partition 14 that cooperates with the lower convex edge 18 is smaller than the inner diameter of the upper convex edge 17 and greater than the inner diameter of the lower convex edge 18. A horizontal partition 14 or a plurality of horizontal partitions 14 can be set, and the partition 14 can be provided with a water-permeable hole or not. In addition, the partition 14 can also be placed on the same height of the inner barrel to arrange a plurality of convex holes. get up.

[0027] The rest of the structure of thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com